Check sizes and dimensions of 700 Bar Flow Control Check Valve

We are supplier and exporter of 10000 psi directional control valve

A 10,000 PSI check valve functions as a specialized valve which enables fluid direction management within high-pressure systems. The valves play essential roles in high-pressure system applications across industries including oil and gas, aerospace industry and hydraulic systems. 10000 psi hydraulic check valve can safely withstand pressure rating of upto 10000 PSI. These valves are manufactured from materials like stainless steel, Nickel alloy and Titanium.

700 Bar Check Valve are known for their strength, durability and resistance to corrosion in different industries. These valves are designed as per international standards. Male X Male 10000 Psi Check Valve are manufactured using high quality material which ensure that it remains operational even under constant stress and fluctuating high-pressure fluid flows.

We are one of the reliable stockist and supplier of Male X Female 10000 Psi Check Valve and exporting it worldwide in more than 25 countries. We use high quality raw material to manufacture Male X Male 10000 Psi Check Valve which are sourced from trusted suppliers, MTC and third party specification certificates are provided with these valves to ensure the quality and standards. Packaging of 10000 PSI NRV Valve are done as per set packaging methods so that it should not get damaged in transportation.

Table of content

- 10000 PSI Check Valve Specification

- 10000 psi hydraulic check valve manufacturing standard

- Different types of 700 Bar Check Valve

- Price list of 10000 psi flow control check valve

- 10000 PSI High Pressure Check Valve dimensions

- Parts and material of 700 Bar High Pressure Check Valve

- Male X Male 700 Bar Check Valve dimensions

- 10000 Psi Male X Female Check Valve dimensions

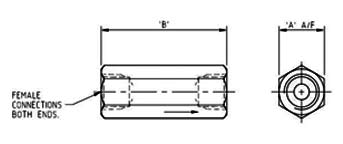

- Female X Female 10000 Psi Check Valve dimensions

- Quality testing of 10000 Psi Pilot Operated Check Valve

- 10000 PSI NRV Valve Application

- Female X Female 10000 Psi Check Valve Advantages

- Working Temperature and Cracking Pressure of 10000 PSI Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

- ASME B16.34

- MSS SP-55

- BS 1868

- ASME B16.10

- API 6D / API 598

- MSS SP-25

- ASME B16.5

10000 psi hydraulic check valve

700 Bar Check Valve

Female X Female 10000 Psi Check Valve

Male X Female 10000 Psi Check Valve

10000 psi flow control check valve

Male X Male 10000 Psi Check Valve

Refer dimensions and price list of 10000 psi hydraulic check valve

| Product | Price (Per Piece) |

|---|---|

| 1/8″ SS Check Valves Female, NPT, 10,000 psi | US $ 20.88 |

| 1/4″ SS Check Valves Female, NPT, 10,000 psi | US $ 25.42 |

| 1″ SS Check Valves Female, NPT, 10,000 psi | US $ 40.42 |

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| Description | Material |

|---|---|

| Body | SS316L |

| Piston | SS316L |

| Gland Washer | SS316L |

| Wheel | SS316L |

| Side Adaptor | SS316L |

| Spring | SS |

| Pressure Rating 100°F (37°C) PSIG | END CONNECTIONS | DIMENSIONS MM | Cv | |

| INLET / OUT LET | L | A/F | ||

| 10000 | 1/8″ | 60 | 19 | 0.82 |

| 10000 | 1/4″ | 68 | 22 | 1.4 |

| 10000 | 3/8″ | 70 | 25 | 1.52 |

| 10000 | 1/2″ | 82 | 27 | 1.7 |

| 10000 | 3/4″ | 85 | 36 | 4.85 |

| 10000 | 1″ | 92 | 45 | 8.3 |

| Pressure Rating 100°F (37°C) PSIG | End Connections |

Hex | Length | |

| Inlet / Out Let | (mm) | (mm) | ||

| 10000 psi | 1/8″ NPT M | 1/8″ NPT F | 19 | 55 |

| 10000 psi | 1/4″ NPT M | 1/4″ NPT F | 22 | 58 |

| 10000 psi | 3/8″ NPT M | 3/8″ NPT F | 25 | 65 |

| 10000 psi | 1/2″ NPT M | 1/2″ NPT F | 27 | 72 |

| 10000 psi | 3/4″ NPT M | 3/4″ NPT F | 36 | 82 |

| 10000 psi | 1″ NPT M | 1″ NPT F | 45 | 85 |

| Pressure Rating 100°F (37°C) PSIG | End Connections | Hex | Length | |

| Inlet / Out Let | (mm) | (mm) | ||

| 10000 psi | 1/8″ NPT F | 1/8″ NPT F | 19 | 55 |

| 10000 psi | 1/4″ NPT F | 1/4″ NPT F | 22 | 58 |

| 10000 psi | 3/8″ NPT F | 3/8″ NPT F | 25 | 65 |

| 10000 psi | 1/2″ NPT F | 1/2″ NPT F | 27 | 72 |

| 10000 psi | 3/4″ NPT F | 3/4″ NPT F | 36 | 82 |

| 10000 psi | 1″ NPT F | 1″ NPT F | 45 | 85 |

Various destructive and non destructive testings are done of 700 Bar Check Valve

- Hydrostatic Testing

- Leak Testing

- Burst Pressure Testing

- Pilot Pressure Sensitivity

- Flow Direction and Blocking Performance

- Material Quality Testing

- Seat Leakage Test

- Pilot Leakage Test

Male X Male 10000 Psi Check Valve are available in NPT, BSP and BSPT threads

- Chemical processing plants

- Hydraulic systems

- Nuclear power plants

- Gas compression systems

- Power plants

- High Pressure Capability

- Reliable Backflow Prevention

- Compact Design

- Multiple Connection Options

- Low Operating Torque

- Factory Tested

| Working Temperature | -10°F to 392°F |

|---|---|

| Cracking Pressure | 1psi to 25psi |