We are trusted Alloy 2507 BSPT Couplings manufacturer in India

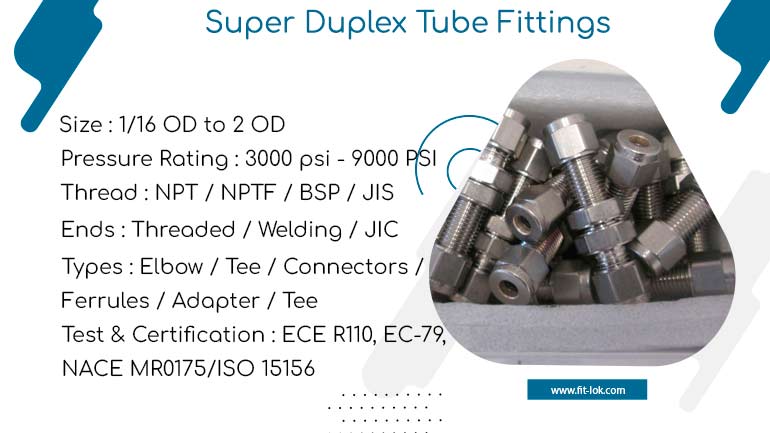

Fit-lok manufactures a comprehensive assortment of Super Duplex 2507 Compression Tube Fittings. The fittings are rigorously designed by the company’s engineers to ensure their versatility and compatibility for a wide range of applications. They employ exceptional raw materials and adhere to worldwide production and quality standards, assuring that their products are of the highest quality.

Fit-lok’s dedicated specialists work hard and constantly update their expertise to fulfil the varying needs of various sectors. The organisation trains its professionals to keep them up to date on the latest breakthroughs in the area.

Discover the impact strength and flexural modulus properties of our en 1.4410 high pressure compression fittings for reliable functionality.

Fit-lok is capable of creating a number of goods in various sizes, shapes, and customised forms, matching the precise operational demands of their clients, using cutting-edge machinery and processes. Super Duplex Compression Tube Fittings are especially beneficial in marine, oil and gas pipes, pharmaceuticals, chemicals, heat exchangers and milling applications.

Fit-lok remains a trustworthy supplier of Super Duplex 2507 Compression Tube Fittings due to their commitment to quality, cutting-edge technology, and professional personnel, responding to the unique requirements of numerous sectors and assuring efficient performance in tough circumstances.

Table of content

- Super duplex 2507 tube fittings Specification

- Types of alloy 2507 compression fittings

- 2507 super duplex male connector chemical composition

- super duplex 1.4501 instrumentation fittings mechanical composition

- en 1.4410 high pressure compression fittings equivalent grade

- Size chart of 25cr super duplex ferrule fittings

- 2507 stainless steel hydraulic fittings Pressure rating

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

|---|---|

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

2507 super duplex male connector

super duplex 1.4501 instrumentation fittings

en 1.4410 high pressure compression fittings

25cr super duplex ferrule fittings

2507 stainless steel hydraulic fittings

1.4507 super duplex flare fittings

| Cr | Ni | Mo | C | N | Mn |

| 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.030 Max | .24-.32 | 1.20 Max |

| Si | Cu | P | S | Fe | |

| 0.80 Max | 0.50 Max | 0.035 Max | 0.020 Max | Balance |

Count on us for high-quality 25cr super duplex ferrule fittings that are suitable for both instrumentation and industrial purposes.

| S32750 / S32760 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000, MPa-550 | Psi – 116000 , MPa – 800 | 15% |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 2507 | S32750/S32760 | – | – | 1.4410 | – | – | – |

You can purchase 2507 stainless steel hydraulic fittings from the supplier at reasonable prices.

| Tube OD (in) | Thread Size (in) | Hex Flat (in) |

|---|---|---|

| 1/16 | 1/16 | 0.31 |

| 1/8 | 1/8 | 0.38 |

| 3/16 | 1/8 | 0.38 |

| 1/4 | 1/4 | 0.46 |

| 5/16 | 1/4 | 0.46 |

| 3/8 | 3/8 | 0.54 |

| 1/2 | 1/2 | 0.71 |

| 5/8 | 1/2 | 0.71 |

| 3/4 | 3/4 | 0.83 |

| 7/8 | 3/4 | 0.83 |

| 1 | 1 | 1.02 |

| Dash Size | Nominal Tube/Pipe Size | SAE100R2 | National Pipe Tapered Fuel (NPTF) | National Pipe Straight Mechanical (NPSM) | JIC 37° Flare Hydraulic SAE J514 | Flareless Compression SAE J514 | ||

| Male | Female | Female Swivel | Male | Female Swivel | ||||

| -02 | 1/8″ | 10000 | 5000 | 6000 | ||||

| -04 | 1/4″ | 5000 | 9500 | 4500 | 5000 | 8500 | 5500 | 6000 |

| -05 | 5/16″ | 4250 | 8500 | 5000 | ||||

| -06 | 3/8″ | 4000 | 8000 | 3500 | 4000 | 7000 | 4000 | 6000 |

| -08 | 1/2″ | 3500 | 6000 | 3500 | 3500 | 6000 | 4000 | 6000 |

| -10 | 5/8″ | 2750 | 5500 | 3000 | 5000 | |||

| -12 | 3/4″ | 2250 | 5000 | 3000 | 3500 | 4000 | 3000 | 4500 |

| -14 | 7/8″ | 2000 | 4000 | 3000 | ||||

| -16 | 1″ | 2000 | 4000 | 2500 | 3000 | 3500 | 2500 | 4000 |

| -20 | 1-1/4″ | 1625 | 3000 | 2000 | 2000 | 3500 | 2000 | |

| -24 | 1-1/2″ | 1250 | 2000 | 1500 | 1500 | 2000 | 1500 | |

| -32 | 2″ | 1125 | 2000 | 1400 | 1500 | 1250 | 1250 | |

Trusted manufacturer of high pressure super duplex 2507 flare fittings

Application of 25cr super duplex ferrule fittings

- Marine applications

- Brewing equipment

- Automotive manufacturing

- Aerospace industry

- Dairy equipment

Packaging of 2507 super duplex male connector

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

Are there any export restrictions or trade compliance requirements for alloy 2507 compression fittings?

Export restrictions and trade compliance requirements for alloy 2507 compression fittings may vary depending on the destination country, and adherence to customs regulations and export control laws is crucial.

What type of testing is performed to ensure the quality of 2507 super duplex male connector?

2507 super duplex male connector undergo a range of tests, including pressure testing, non-destructive testing (NDT), and metallurgical analysis, to verify their mechanical properties and integrity.

How are super duplex 1.4501 instrumentation fittings packed to ensure safe transportation?

super duplex 1.4501 instrumentation fittings are carefully packed in suitable packaging materials, such as wooden crates or boxes, with proper cushioning and protection, to prevent damage during transit.

What certifications are available for en 1.4410 high pressure compression fittings?

en 1.4410 high pressure compression fittings can be accompanied by certifications such as ISO 9001:2015 quality management system certification, NACE MR0175 compliance, and PED (Pressure Equipment Directive) certification, demonstrating their quality and compliance with industry standards.

Are 25cr super duplex ferrule fittings eligible for material traceability documentation?

Yes, 25cr super duplex ferrule fittings can be provided with material traceability documentation, including heat numbers, lot numbers, and mill test reports (MTRs), to ensure the traceability of the materials used in their manufacturing process.