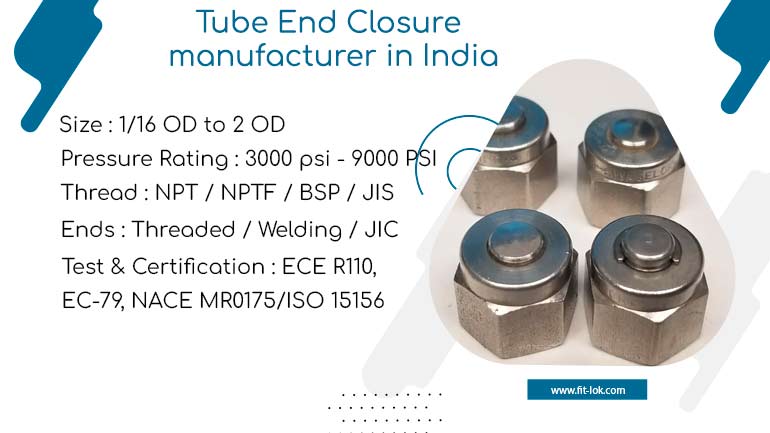

We are leading SS pipe end closures manufacturer in India

Tube end closures, also known as tube end caps or tube end plugs, fulfil this critical function by providing a dependable and leak-free seal for tube ends. Tube end closures are specialised fittings used to securely close off the open ends of tubes and pipes. They are available in a variety of forms and sizes to accommodate various tube dimensions and materials. Tube end closures can be threaded to screw into the male threads of the tube or have a smooth inner surface to fit over the outside diameter of the tube. Their principal function is to form a tight seal, preventing fluids or gases from escaping and protecting the fluid system’s integrity.

Refer dimensions and sizes of Double Ferrule Fittings

Tube end closures’ principal function is to seal off the open ends of tubes and pipes. It provides a secure and leak-free seal by putting the closure over the open end of the tube or screwing it into the tube’s male threads. Tube end closures keep fluids or gases kept within the system, reducing the danger of leaks, contamination, and damage. Because of their capacity to form secure seals, ease of installation, and versatility, they are vital in a wide range of plumbing and industrial applications.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

pipe end closures

Tube End Closure Double Ferrule Fittings

End Closure fittings

Stainless steel Tube End Closure

SS pipe end closures

Fitting End Closure

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

End Closure fittings supplier in India, cheapest rates

- Automotive applications

- Aerospace industry

- Water treatment

- Marine applications

- HVAC systems

Manufacturer of medium pressure SS pipe end closures up to 22 500 psi

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Exporter of Fitting End Closure, Easy installation which result 80% reduction in labor cost

Packaging of tube end closures

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

Is it possible to standardize tube end closures?

Standard sizes and designs for tube end closures exist, particularly for threaded fittings or flanges that adhere to industry standards such as ANSI, DIN, or ISO. However, depending on the application, customized or specialized tube end closures may be required.

Is it possible to reuse pipe end closures?

Pipe end closures that are in good shape and have not been damaged or deformed during previous use can typically be reused. However, before reusing them, inspect them for signs of wear, corrosion, or deterioration to ensure they maintain a stable seal.