Top notch Hydraulic SAE Mono Flanges manufacturer in India

Our SAE 6162 Mono Flanges are used for Hose assembly where required removal of piping may be possible within close area Mono Flanges are in two halves attached by Weld nozzle along with Allen bolts, Nuts & O-ring Seal.

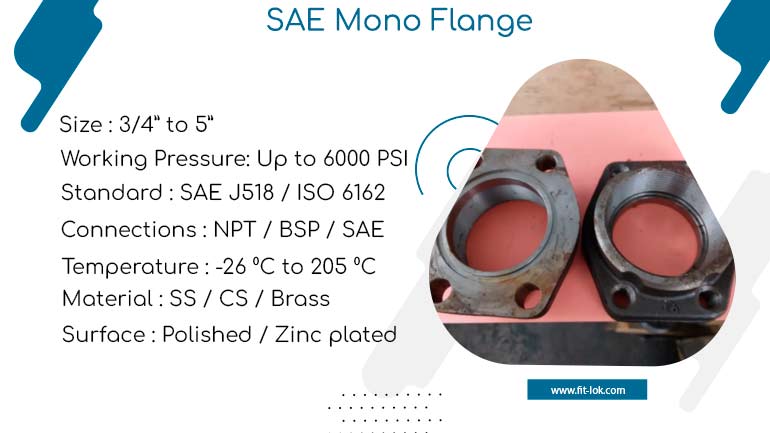

SAE 6162 Mono Flanges, single or known as one piece flanges, are Hydraulic connectors for joining elements in the fluid power system. Mono flanges differ from split flanges in that the piece is created monolithically, making it easier for them to be put in place without needing to join two parts using bolts. These flanges have an O-ring groove to contain a sealing component to minimize or eradicate leakage at high pressure conditions. There are lots of tube sizes that are on the markets today and Mono Flanges can accommodate both metric and inch-sized tubes. Fit-Lok is a trusted SAE Mono Flanges manufacturer in India in wide range of sizes.

Mono Flanges are available in size range of 3/8″ to 5″

Made out of high quality carbon steel, stainless steel or alloy steel materials, these flanges showcase tremendous amounts of wear, corrosion and mechanical abuse. Categorized for usage under pressures higher than 6,000 psi and more, the SAE 6162 Mono Flanges do not disappoint in performance.

We are exporter and supplier of Mono flanges in more than 20 countries including Spain, USA and Saudi Arabia. When it comes to sealing against fluctuating temperatures and pressures, the O-ring groove is most accurately tooled in such a manner. As with all the mono flanges, one piece means you do not have to align two halves and bolt them, thus saving time during installation. The following are the highlights of these flanges; While they come in different sizes, they can effectively fit different applications, right from the small machinery to the industrial ones.

When selecting a correct mono flange for an application the user has to consider aspects such as the operating pressure, the type of fluid, as well as the environemental conditions. Where there is high pressure it may be necessary to use alloy steel material, while where the conditions are acidic or otherwise causing corrosion, stainless steel materials are used. Proper installation is critical and a must to guarantee direction of service of the flange; this entails right tightening of the bolt and checking if the O-ring is in its right position.

Table of content

| Type | SAE 6162 Mono Flanges |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE 6162 Mono Flanges

Hydraulic SAE Mono Flanges

Mono Flanges

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Versatility

- Material Variety

- Standardized Design

- High Pressure Capability

- Leakage Prevention

- Building Machinery

- Agricultural Machinery

- Forestry Machinery

- Paper Processing

- Mobile Hydraulics

- Lifting and Material Handling Equipment