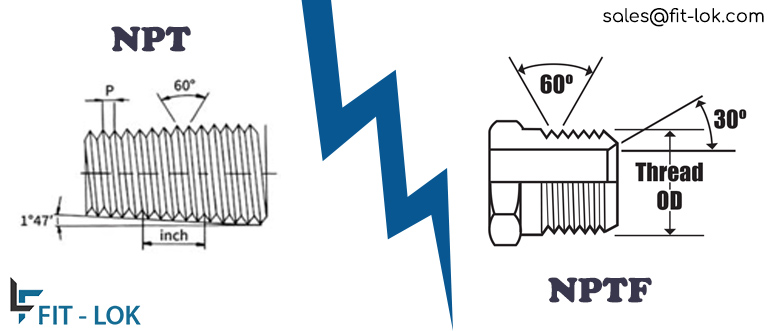

Both the threads are almost same, the difference lies in the way they create a leak proof seal. For NPTF threads there is no need of thread sealant, but while we are installing NPT threads fittings sealant is a very important to create a leak proof seal. Therefore NPFT threads can create leak proof mechanical seal without the use of sealant, its not likely possible with NPT threads. NPT is general purpose tapered pipe thread whereas NPTF is dryseal tapered pipe thread.

Full form and Standard of NPT

NPT = National Pipe Taper Thread (ANSI B1.20.1)

Full form and Standard of NPTF

NPTF = National Pipe Taper Thread Fuel (ANSI B1.20.3)

Know the exact difference between NPT and NPTF Threads

Difference between NPT and FNPT

NPT and FNPT are both tapered thread standards but FNPT specifically refers to the female threads which are internal, whereas NPT can refer to both Male or Female threads. Both NPT and FNPT requires sealant for leak proof connection.

NPT vs NPTF compatibility

NPT and NPTF threads both have same basic form and taper but they are not fully compatible due to there sealing mechanism. We may use NPT fittings with NPTF fittings but its not recommended for high pressure and high temperature applications because of potential for leaks. Using mismatched threads can compromise overall system integrity therefore its not reliable to use NPT and NPTF threads together.

Check NPTF Thread in Hydraulic Fittings Connections

NPT vs. NPTF in Gas Line Applications

For Gas Line application NPTF is much better option in comparison to NPT threads. NPTF is specifically designed for fuel and gas applications where leaks can be very dangerous. Due to the sealant requirement and installation process of NPT threads have higher chances of leak potential if properly not sealed.

NPTF threads are formed as per ASME B1.20.3 standards and specifically developed for fuel and fluid power systems which are high pressure and high temperature applications.

NPT vs. NPTF in Harsh Environments

In harsh enviroments like Corrosive atmospheres, High humidity and Extreme temperatures threaded connection may become vulnerable.

NPT threads relied on sealant to prevent leakage but over a time micro gaps between threads can trap moisture, corrosive chemicals or gas which eventually may lead to Pitting corrosion or Sealant breakdown if maintenance have been not done properly. NPTF threads works on dryseal design which minimizes voids where corrosive elements can enter. Less reliance on sealant and Full thread flank contact makes NPTF threads a good choice in Harsh Environments.

Refer the advantages of ASME B 1.20.3 Thread

Characteristics of NPT threads

- Tapered Design

- Male and Female Thread Compatibility

- Standardized Angles

- Self-Sealing

- Pressure Resistance

- Non-Interchangeability

Are NPT and NPTF interchangeable

NPT and NPTF threads are not fully interchangeable because of the difference between thread profiles and sealing mechanism. Although they appear same but NPTF threads are mainly used for dry seal application whereas NPT threads are for general purpose application.

NPT thread chart

| Major Diameter mm | Tapping Drill Size | TPI | Pitch P mm | |

|---|---|---|---|---|

| NPT 1/16″ | 7,90 | 6,00 | 27,0 | 0,94 |

| NPT 1/8″ | 10,24 | 8,25 | 27,0 | 0,94 |

| NPT 1/4″ | 13,62 | 10,70 | 18,0 | 1,41 |

| NPT 3/8″ | 17,06 | 14,10 | 18,0 | 1,41 |

| NPT 1/2″ | 21,22 | 17,40 | 14,0 | 1,81 |

| NPT 3/4″ | 26,57 | 22,60 | 14,0 | 1,81 |

| NPT 1″ | 33,23 | 28,50 | 11,5 | 2,21 |

| NPT 1 1/4″ | 41,99 | 37,00 | 11,5 | 2,21 |

| NPT 1 1/2″ | 48,05 | 43,50 | 11,5 | 2,21 |

| NPT 2″ | 60,09 | 55,00 | 11,5 | 2,21 |

| NPT 2 1/2″ | 72,70 | 65,50 | 8,0 | 3,18 |

| NPT 3″ | 88,61 | 81,50 | 8,0 | 3,18 |

| NPT 3 1/2″ | 101,32 | 94,30 | 8,0 | 3,18 |

| NPT 4″ | 113,97 | 107,00 | 8,0 | 3,18 |

| NPT 5″ | 141,30 | 134,38 | 8,0 | 3,18 |

| NPT 6″ | 168,28 | 161,19 | 8,0 | 3,18 |

| NPT 8″ | 219,08 | 211,67 | 8,0 | 3,18 |

| NPT 10″ | 273,05 | 265,31 | 8,0 | 3,18 |

| NPT 12″ | 323,85 | 315,79 | 8,0 | 3,18 |

American Pipe threads in comparison

| NPT ANSI B1.20 |

NPTF ANSI B1.20.3 |

NPSC ANSI B1.20 |

NPSM ANSI B1.20 |

|

|---|---|---|---|---|

| Internal thread | taper | taper | cylindrical | cylindrical |

| External thread | taper | taper | taper (=NPT) | |

| Applications | general applications, non-sealing |

drysealing | general applications, non-sealing |

View NPTF thread chart and angle

NPT vs NPTF sizes

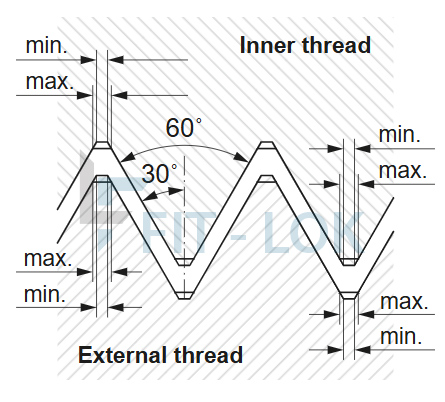

NPT

| height of profile | width of flat of profile | |||

| P [G/"] | min. | max. | min. | max. |

| 8 | 2,356 | 2,540 | 0,122 | 0,229 |

| 11,5 | 1,590 | 1,767 | 0,084 | 0,185 |

| 14 | 1,288 | 1,451 | 0,069 | 0,163 |

| 18 | 0,974 | 1,129 | 0,053 | 0,145 |

| 27 | 0,634 | 0,753 | 0,036 | 0,104 |

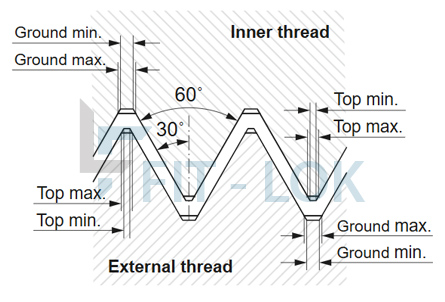

NPTF

| width of flat of profile | ||||

| ground | top | |||

| P [G/"] | min. | max. | min. | max. |

| 8 | 0,203 | 0,279 | 0,152 | 0,203 |

| 11,5 | 0,152 | 0,229 | 0,102 | 0,152 |

| 14 | 0,127 | 0,178 | 0,076 | 0,127 |

| 18 | 0,127 | 0,178 | 0,076 | 0,127 |

| 27 | 0,102 | 0,152 | 0,051 | 0,102 |

Check threads and angle of NPT connections

NPT VS NPTF Thread Dimensions

| Dimension | NPT | NPTF |

| Truncation | Requires sealant, Wider tolerance | Mechanical seal, Tighter tolerance |

| Taper | 1/16 inch per inch | 1/16 inch per inch |

| Standard | ASME B1.20.1 | ASME B1.20.1 |

| Seal Method | Sealant, Thread deformation | Interference fit (mechanical) |

Why NPTF is specifically designed for fuel and fluid systems

Fuel and fluid systems needs to be absolutely leak free to prevent any unwanted situation. Metal to Metal seal from NPTF threads significantly reduces this risk of leakage. These are specifically engineered to meet the stringent requirements of fuel lines, where leaks can cause contamination or fuel loss. NPTF threads performs better in high pressure environments. Therefore due to safety and performace factors NPTF threads are used in fuel and fluid systems.

Can I use PTFE tape with NPTF fittings?

NPTF fittings are not required sealants due to their dry seal mechanism even though you can use PTFE tape as a sealant for extra protection in high pressure application.

How to choose the right thread type for my system?

To select a right thread you need to consider a fluid type, pressure requirements and the region in which you are working because NPT threads are normally use in American region whereas BSP threads are widely use in Europe region. Also make sure thread type is same throughout the system to prevents leaks and failures.

Why NPTF threads are used instead of NPT threads

Since there is no need of sealant in NPTF threads due to there dryseal mechanism, Its is used in application where sealants could contaminate the gases or fluids flowing through it. Sometimes sealant may fail due to high pressure and high temperature condition to prevent it to happen NPTF threads are used.