Leading CF8M Wafer Check Valve Manufacturer in India

Exporter of stainless steel wafer check valve wordlwide, View price list of ss316 check valve

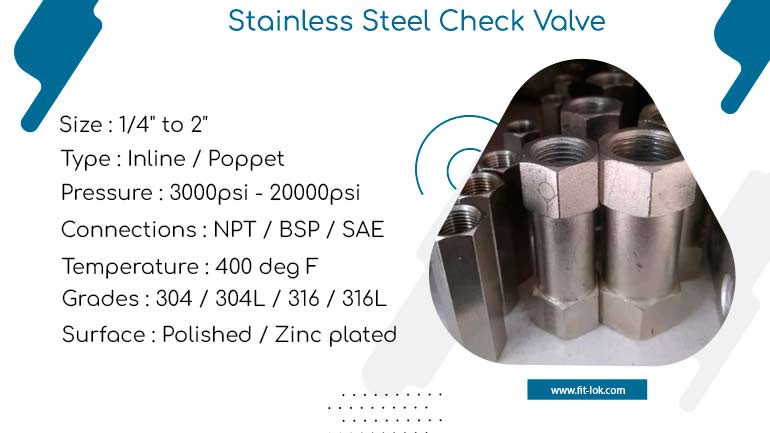

Fit-Lok is one of the most trusted manufacturer and supplier of Stainless steel check valve in wide range of sizes, pressure rating and types. Primary function of CF8M Wafer Check Valve is to keep the flow of media such as oil, gas or water in one direction. Before purchasing these valves please make sure that you know the required pressure rating and size and connection required to fit. We keep ready stock of ss316 check valve in range of 3000 PSI to 20000 PSI. These valves make sure that pressure flow is in right directions especially when the pressure condition of media can reverse the flow.

Stainless steel swing check valve have superior corrosion resistence ability and can withstand a higher temperature range. These valves comes with O-ring seal which helps to secure these valves and minimizes leakage risk. We have established ourselves as trusted Stainless steel check valve manufacturer in India. These valves have to pass through more than 15 destructive and non-destructive tests to make sure that they will not fail in live conditions.

We are exporting AISI 304 spring check valve in USA, UAE, Malaysia and Spain, We are known for delivering before delivery timelines which makes us suitable choice for your application. We also keep ready stock of high pressure stainless steel check valve in standard sizes and pressure rating to immediate dispatch. Simple design and durable material of stainless steel foot valve makes it better choice in various application due to its minimum maintenance requirements and reduced costs.

Table of content

- Stainless steel check valve specification

- Types of SS check valve

- 316 SS check valve price list

- Stainless steel spring check valve chemical composition

- Stainless steel dual check valve mechanical properties

- Stainless steel double check valve equivalent grade

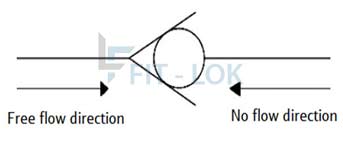

- Symbol of SS instrumentation check valve

- Functions of SS threaded check valve

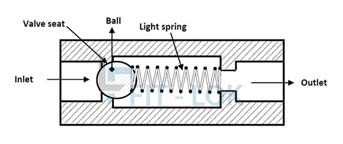

- Diagram of Stainless steel Check Valve

- Dimensions of Stainless steel hydraulic check valve

- Application of CF8M check valve

- Temperature limit and cracking pressure of stainless steel foot valve

- Features of SS316 check valve

- Parts and material of SS check valve

- AISI 304 Male to Male Check valve Dimensions

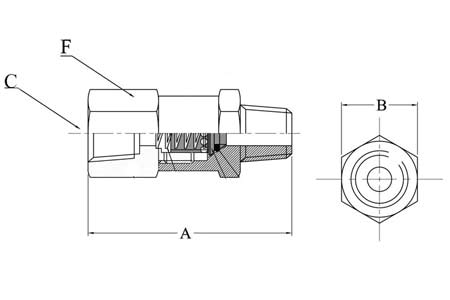

- Stainless steel 316 Male to Female Check valve Dimensions

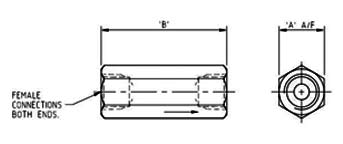

- SS 316L Female to Female Check valve Dimensions

- Size chart of SS 304L Spring Check Valve

- Ready Stock list of SS check valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Various testing are performed on stainless steel swing check valve, Reliable supplier of ss disc check valve

Stainless steel Hydraulic Check Valve

SS Inline Check Valve

Stainless Steel 304 Nrv Valve

SS 316 Non Return Valve

AISI 316L Spring Check Valve

Alloy 304L Instrumentation Check Valve

Stainless steel 316 Poppet Check Valve

SUS 304 Instrument Control Valve

SS 304 Instrument Air Check Valve

| Product | Price (Per Piece) |

| 1/4″ SS NPT Check Valve | US $ 28.33 |

| SS 304 hydraulic check valve, G 1/8″, PN350 | US $ 24.48 |

For more updated and latest price list contact on sales@fit-lok.com

| Grade | S | Mn | C | Si | Ni | P | Cr | Mo | Ti | N | Fe | |

| 304 | min. | 8.0 | 18.0 | |||||||||

| max. | 0.030 | 2.0 | 0.08 | 0.75 | 10.5 | 0.045 | 20.0 | 0.10 | ||||

| 304L | min. | 8.0 | 18.0 | |||||||||

| max. | 0.030 | 2.0 | 0.030 | 0.75 | 12.0 | 0.045 | 20.0 | 0.10 | ||||

| 316 | min. | 10.0 | 16.0 | 2.03.0 | ||||||||

| max. | 0.030 | 2.0 | 0.035 | 0.75 | 14.0 | 0.045 | 18.0 | |||||

| 316L | min. | 10.0 | 16.0 | 2.03.0 | ||||||||

| max. | 0.030 | 2.0 | 0.035 | 0.75 | 14.0 | 0.045 | 18.0 | |||||

| 317 | 0.030 max | 2 max | 0.08 max | 1 max | 0.045 max | 18.00 20.00 | 3.00 4.00 | 57.845 min | ||||

| SS 317L | 0.030 max | 2.0 max | 0.035 max | 1.0 max | 11.00 15.00 | 0.045 max | 18.00 20.00 | 3.00 4.00 | 57.89 min | |||

| SS 321 | 0.030 max | 2.0 max | 0.08 max | 1.0 max | 9.00 12.00 | 0.045 max | 17.00 19.00 | 5(C+N) 0.70 max | 0.10 max | |||

| SS 321H | 0.030 max | 2.0 max | 0.04 0.10 | 1.0 max | 9.00 12.00 | 0.045 max | 17.00 19.00 | 4(C+N) 0.70 max | 0.10 max | |||

| 347/ 347H | 0.030 max | 2.0 max | 0.08 max | 1.0 max | 9.0013.00 | 0.045 max | 17.00 20.00 | |||||

| 904L | min. | 23.00 | 19.0 | 4.00 | 0.10 | |||||||

| max. | 0.035 | 2.00 | 0.20 | 1.00 | 28.00 | 0.045 | 23.0 | 5.00 | 0.25 | |||

| Grade | Elongation | Melting Point | Yield Strength (0.2%Offset) | Density | Tensile Strength |

| 304/ 304L | 35 % | 1400 °C (2550 °F) | Psi 30000 , MPa 205 | 8.0 g/cm3 | Psi 75000 , MPa 515 |

| 310 | 40 % | 1402 °C (2555 °F) | Psi 30000 , MPa 205 | 7.9 g/cm3 | Psi 75000 , MPa 515 |

| 316 | 35 % | 1400 °C (2550 °F) | Psi 30000 , MPa 205 | 8.0 g/cm3 | Psi 75000 , MPa 515 |

| 316L | 35 % | 1399 °C (2550 °F) | Psi 30000 , MPa 205 | 8.0 g/cm3 | Psi 75000 , MPa 515 |

| 317 | 35 % | 1400 °C (2550 °F) | Psi 30000 , MPa 205 | 7.9 g/cm3 | Psi 75000 , MPa 515 |

| 321 | 35 % | 1457 °C (2650 °F) | Psi 30000 , MPa 205 | 8.0 g/cm3 | Psi 75000 , MPa 515 |

| 347 | 35 % | 1454 °C (2650 °F) | Psi 30000 , MPa 205 | 8.0 g/cm3 | Psi 75000 , MPa 515 |

| 904L | 35 % | 1350 °C (2460 °F) | Psi 32000 , MPa 220 | 7.95 g/cm3 | Psi 71000 , MPa 490 |

| STANDARD | AFNOR | EN | UNS | BS | JIS | GOST | WERKSTOFF NR. |

| 304 | Z7CN18‐09 | X5CrNi18-10 | S30400 | 304S31 | SUS 304 | 08Х18Н10 | 1.4301 |

| 304L | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 | S30403 | 3304S11 | SUS 304L | 03Х18Н11 | 1.4306 / 1.4307 |

| 310 | – | X15CrNi25-20 | S31000 | 310S24 | SUS 310 | 20Ch25N20S2 | 1.4841 |

| 316 | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | S31600 | 316S31 / 316S33 | SUS 316 | – | 1.4401 / 1.4436 |

| 316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | S31603 | 316S11 / 316S13 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 1.4404 / 1.4435 |

| 317 | – | – | S31700 | – | SUS 317 | – | 1.4449 |

| 317L | – | X2CrNiMo18-15-4 | S31703 | – | SUS 317L | – | 1.4438 |

| 321 | – | X6CrNiTi18-10 | S32100 | – | SUS 321 | – | 1.4541 |

| 321H | – | X12CrNiTi18-9 | S32109 | – | SUS 321H | – | 1.4878 |

| 347 | – | X6CrNiNb18-10 | S34700 | – | SUS 347 | 08Ch18N12B | 1.4550 |

| 347H | – | X6CrNiNb18-12 | S34709 | – | SUS 347H | – | 1.4961 |

| 904L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 | N08904 | 904S13 | SUS 904L | STS 317J5L | 1.4539 |

- It prevents backflow

- Its used to maintain system pressure

- Ensure safety

- Protect Equipment

Check sizes and dimensions of stainless steel foot valve, Refer AISI 304 spring check valve working principle

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

- Aerospace

- HVAC Systems

- Food Processing

- Water Treatment

- Oil and Gas

- Marine Engineering

| Working Temperature | Cracking Pressure |

|---|---|

| -10°F (-23°C) to 392°F (200°C) | 1psi to 25psi |

We manufacture high pressure stainless steel check valve which can withstand pressure rating in range of 3000PSI to 10000PSI

- Non-return valve

- Durability

- Ease of Installation

- Corrosion-resistant

- Minimal maintenance

| Component | Material |

| Body | SS 316 |

| Spring | SS 316 |

| Poppet | SS 316 |

| Nut | SS 316 |

| O-ring | Viton |

| Joint (O-ring) | Viton |

| Adaptor | SS 316 |

| Front Ferrule | SS 316 |

| Back Ferrule | SS 316 |

| END CONNECTIONS | DIMENSIONS in MM | PRESSURE RATING 100°F (37°C) PSIG | Cv | ||

| INLET / OUT LET | L | A/F | |||

| MALE x MALE NPT | 1/8″ | 60 | 19 | 6000 | 0.82 |

| 1/4″ | 68 | 22 | 6000 | 1.40 | |

| 3/8″ | 70 | 25 | 6000 | 1.52 | |

| 1/2″ | 82 | 27 | 6000 | 1.70 | |

| 3/4″ | 85 | 36 | 6000 | 4.85 | |

| 1″ | 92 | 45 | 6000 | 8.30 | |

| A | B (A/F) | C | F (A/F) |

| 62 | 19 | 1/8″ | 19 |

| 62 | 19 | 1/4″ | 19 |

| 62 | 22 | 3/8″ | 22 |

| 75 | 28.5 | 1/2″ | 28.5 |

| 78 | 32 | 3/4″ | 32 |

| 90 | 41 | 1″ | 41 |

| END CONNECTIONS | PRESSURE RATING 100°F (37°C) PSIG | Hex | Length | |

| INLET / OUT LET | (mm) | (mm) | ||

| 1/8″ NPT F | 1/8″ NPT F | 15000 psi | 19 | 55 |

| 1/4″ NPT F | 1/4″ NPT F | 15000 psi | 22 | 58 |

| 3/8″ NPT F | 3/8″ NPT F | 15000 psi | 25 | 65 |

| 1/2″ NPT F | 1/2″ NPT F | 15000 psi | 27 | 72 |

| 3/4″ NPT F | 3/4″ NPT F | 15000 psi | 36 | 82 |

| 1″ NPT F | 1″ NPT F | 15000 psi | 45 | 85 |

Condition

Minimum Opening Pressure: 1 PSI

Minimum Pressure: 3,000 psi @ 70° F

Temperature Range: 35° – 300° F

| Pipe Size |

Flow Coefficient (Cv) |

End—End Lg.0 |

|

NPT Female × NPT Female

|

||

| 3/4 | 9 | 3 5/16″ |

| 3/8 | 3.09 | 2 5/8″ |

| 1/4 | 1.01 | 2 5/8″ |

| 1/2 | 4.03 | 2 5/8″ |

| 1 | 11.09 | 3 11/16″ |

|

NPT Male × NPT Male

|

||

| 3/4 | 9 | 3 13/16″ |

| 3/8 | 3.09 | 3 13/16″ |

| 1/4 | 1.01 | 3 13/16″ |

| 1/2 | 4.03 | 3 13/16″ |

| SS 316L High Pressure Check Valve | Stainless steel 304 Female to Female Check valve |

| SS 304L Female to Male Check valve | Stainless steel 316 Spring Check Valve |

| 3/4″ NPTF SS 347 Check Valve | 304 Stainless steel Inline Check Valve |

| SUS 316L Instrument Control Valve | 316L Stainless steel Piston Check Valve |

| 3/4″ NPTM x 3/4″ NPTM Stainless steel 316L Check Valve | 316 Stainless steel Poppet Check Valve |

| 1/2″ NPTF AISI 321 Check Valve | Stainless steel Male to Female Check valve |

| AISI 316 Male to Male Check valve | 316 Stainless steel Instrument Air Check Valve |

| Stainless steel 316 NRV Valve | SS Instrumentation Check Valve |

| 1/2″ NPTM x 1/2″ NPTM 304L SS Check Valve | Stainless steel 316L Hydraulic Check Valve |

| AISI 304L Non Return Valve | 1/4″ NPTM x 1/4″ NPTM AISI 304 Check Valve |

| 1/4″ NPTF 316 SS Check Valve | 1″ NPTF Stainless steel 904L Check Valve |