Alloy 625 Poppet Check Valves Manufacturer in India

Buy Inconel 600 Instrumentation Check Valve at 20% discounted price

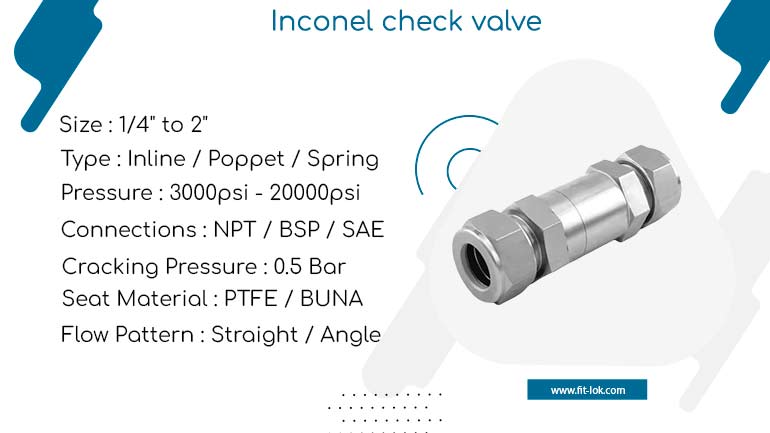

Inconel check valve is known for its high tensile strength, creep strength and fatigue strength. These valves can perform well at low as well as high temperature. Alloy 625 Poppet Check Valves are design to work well in high temperature application but due to its high chromium and molybdenum content it also provides high resistance to corrosive media. These valves are generally resistant to fatigue and chloride pitting stress. We are trusted Inconel check valve manufacturer in India which are widely used in acids, alkalis, and chlorides conditions.

Fit-Lok is reliable supplier and exporter of Alloy 825 Non Return Check Valves which we have exported to UAE, Oman and Qatar. These valves are designed to handle high flow condition without getting damaged. We source raw material from EN 10204 3.1 certified suppliers to maintain quality of our products. Nickel 625 check valve are available in different designs such as lift check, swing, ball and spring-loaded configuration.

Inconel 600 Instrumentation Check Valve uses a single-piece body constructed from bar stock material with socket weld connection ends. These components operate under the highest pressure drops possible. The Incoloy 825 Threaded Check Valve finds applications in highly corrosive environments as well as moderately reducing and oxidizing environments. These valves are widely used in industries like petroleum and oil and gas where downtime of hydraulic system can be very costly.

Every Inconel 600 foot valve is 100% tested and quality checked. These valves are durable, break proof and leak proof. We provide Third party test inspections on demand to our buyers. We have tied up with several shipping companies which ensures that we will deliver our product within a decided time.

Table of content

- Inconel check valve specification

- Alloy 625 check valve price list

- Various types of Inconel check valve

- Weight chart of Inconel 600 Check Valve

- Inconel hydraulic check valve chemical composition

- Inconel alloy Check valve mechanical properties

- Inconel instrument control check valve equivalent grade

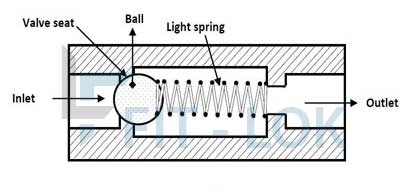

- Diagram of Inconel 600 Instrumentation Check Valve

- Incoloy 825 Threaded Check Valve Features

- Applications of Alloy 825 Non Return Check Valves

- DIN 2.4856 Instrumentation Check Valve standards

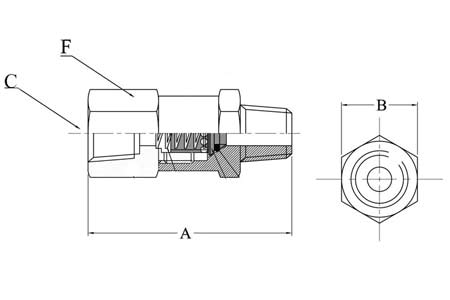

- Inconel 601 Male to Female check valve dimensions

- Pressure temperature rating of Inconel 625 Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Price of Nickel 600 NRV Valve vary between 15$ to 150$ per piece based on pressure rating, size, material, design and flow rate. For updated price list of DIN 2.4856 Spring Check Valve you can contact us on sales@fit-lok.com

Inconel Hydraulic Check Valve

Alloy 601 Inline Check Valve

Nickel 600 Nrv Valve

Inconel 625 Instrument Air Check Valve

Inconel 600 Non Return Valve

DIN 2.4856 Spring Check Valve

UNS N06625 Instrumentation Check Valve

Incoloy 825 Poppet Check Valve

Nickel 625 Instrument Control Valve

View sizes and dimensions of Incoloy 825 Threaded Check Valve and Inconel 625 Check Valve

| BW | lb | 44 | 33 | 51 | 113 | 93 | 149 |

| kg | 20 | 15 | 23 | 51 | 42 | 67 | |

| RF | lb | 444 | 289 | 667 | 1236 | 1002 | – |

| kg | 200 | 130 | 300 | 556 | 451 | – | |

| Size | IN | 10 | 8 | 12 | 16 | 14 | – |

| DN | 250 | 200 | 300 | 400 | 350 | – | |

| RF | lb | 53 | 42 | 62 | 140 | 107 | 176 |

| kg | 24 | 19 | 28 | 63 | 48 | 79 | |

| Size | IN | 2.5 | 2 | 3 | 5 | 4 | 6 |

| DN | 65 | 50 | 80 | 130 | 100 | 150 | |

| BW | lb | 360 | 262 | 524 | 1042 | 716 | – |

| kg | 162 | 118 | 236 | 469 | 322 | – |

| Grade | Ni | C | S | Mn | Si | Cu | Fe | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72.00 min | 0.15 max | 0.015max | 1.00 max | 0.50 max | 0.50 max | 6.00 – 10.00 | 14.00 – 17.00 |

| Inconel 601 | 58.0 – 63.0 | 0.10 max | 0.015 max | 1.0 max | 0.5 max | 1.0 max | Balance | 21.0 – 25.0 |

| Inconel 625 | 58.0 min | 0.10 max | 0.015 max | 0.50 max | 0.50 max | – | 5.0 max | 20.0 – 23.0 |

| Inconel 718 | 50.00 – 55.00 | 0.08 max | 0.015 max | 0.35 max | 0.35 max | 0.30 max | – | 17.00 – 21.00 |

| Element | Elongation | Tensile Strength | Density | Melting Point | Yield Strength (0.2%Offset) |

|---|---|---|---|---|---|

| Inconel 600 | 40 % | Psi – 95,000 , MPa – 655 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 45,000 , MPa – 310 |

| Inconel 601 | 30 % | Psi – 80,000 , MPa – 550 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 30,000 , MPa – 205 |

| Inconel 625 | 42.5 % | Psi – 1,35,000 , MPa – 930 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 517 |

| Inconel 718 | 45 % | Psi – 1,35,000 , MPa – 930 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 482 |

| STANDARD | UNS | WNR | BS | JIS | EN | GOST | AFNOR |

| Inconel 600 | N06600 | 2.4816 | NA 13 | NCF 600 | NiCr15Fe | МНЖМц 28-2,5-1,5 | NC15FE11M |

| Inconel 601 | N06601 | 2.4851 | NA 49 | NCF 601 | NiCr23Fe | XH60BT | NC23FeA |

| Inconel 625 | N06625 | 2.4856 | NA 21 | NCF 625 | NiCr22Mo9Nb | ХН75МБТЮ | NC22DNB4M |

Alloy 825 Non Return Check Valves comes in various threads such as NPT, BSPP, BSPT and UNF thread

- Pressure and Temperature Resistance

- Durability

- Compact Design

- Versatility

- Ease of Maintenance

Inconel 600 foot valve widely used in pressure transmitters and pressure gauges

- Aerospace Industry

- Oil and Gas Industry

- Nuclear Power Plants

- Power Generation

- Chemical Processing

- Offshore Platforms

- Industrial Gas Systems

- DIN3352

- ASME B16.34

- ASME B16.5

- ASME B16.10

- ASME B16.25

- ASME B16.11

- BS 5352

- ASTM A494 / ASME SA494 API 602

- ASME B1.20.1

| A | B (A/F) | C | F (A/F) |

| 62 | 19 | 1/8″ | 19 |

| 62 | 19 | 1/4″ | 19 |

| 62 | 22 | 3/8″ | 22 |

| 75 | 28.5 | 1/2″ | 28.5 |

| 78 | 32 | 3/4″ | 32 |

| 90 | 41 | 1″ | 41 |

| Material | Alloy 625 | Alloy 825 |

|---|---|---|

| Temperature, °F (°C) | Working Pressure, psig (bar) | |

| –10 (–23) to 100 (37) | 6000 (413) | 6000 (413) |

| 200 (93) | 6000 (413) | 5510 (379) |

| 250 (121) | 6000 (413) | 5370 (369) |

| 300 (148) | 6000 (413) | 5225 (360) |

| 350 (176) | 5940 (409) | 5110 (352) |

| 400 (204) | 5880 (405) | 4995 (344) |