Reliable Alloy 2507 Poppet Check Valve Manufacturer in India

View pressure rating and price list of ASTM A479 2507 Spring Check Valves

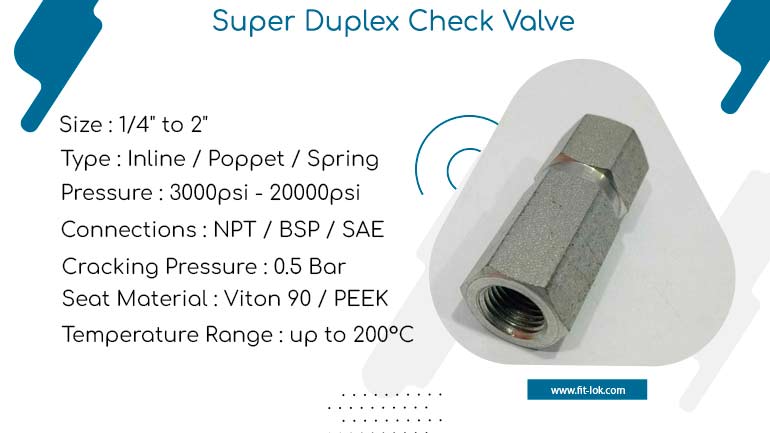

Fit-lok is trusted Super Duplex Check Valve manufacturer in India in different sizes and pressure rating. These valves are known for withstanding high pressure and temperature rating. Alloy 2507 Poppet Check Valve contains upto 25% chromium, 7% nickel and 4% molybdenum. High content of these materials makes Super Duplex 2507 Check Valve extremely resistant chloride pitting and crevice corrosion attack. Uses of these valves should be limited to applications below 600° F.

The 2507 Duplex High Pressure Check Valve has two ports to enable unidirectional gas flow while blocking backward movement. Stress corrosion cracking does not affect the UNS S32750 Instrumentation Check Valve performance. The device allows simple customization for different application needs. The properties of Super Duplex 2507 Check Valve make them suitable for various industrial applications. These valves requires minimum maintenance and can be used for longer period of time.

We are one of the most renowned supplier and exporter of ASTM A276 S32750 One Way Check Valve to the different industries like Oil and Gas, Petroleum industry, seawater desalination plants around the world. UNS S32750 Instrumentation Check Valve are manufactured in the guidance of expert team using quality raw materials and as per international standards. Upon request of clients we also performs third party test and documents are provided for the same.

We are known for our quality ASTM A479 2507 Spring Check Valves and do not compromise in quality of these valves. We are stocking and supplying these Super Duplex Check Valve to various countries Malaysia, Algeria, Bahrain and UAE in different sizes, threads and pressure rating.

Table of content

- Super Duplex Check Valve Specification

- Various types of SDSS Check Valves

- Alloy 2507 Check Valve Price list

- Material of construction of ASTM A479 2507 Spring Check Valves

- Pressure temperature rating of UNS S32750 Spring Check Valves

- Super Duplex 2507 Check Valves Dimensions

- Super duplex hydraulic check valve chemical composition

- SDSS control check valve mechanical properties

- Super Duplex high pressure check valve equivalent grade

- Physical Properties of ASTM A276 S32750 One Way Check Valve

- UNS S32750 Instrumentation Check Valve Testing

- Alloy 2507 Poppet Check Valves Advantages

- SDSS 2507 Instrument Check Valve Applications

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Super Duplex Hydraulic Check Valve

SDSS 2507 Inline Check Valve

ASTM A276 UNS S32750 Nrv Valve

DIN 1.4410 Instrument Air Check Valve

Super Duplex 2507 Non Return Valve

UNS S32760 Spring Check Valve

Alloy 2507 Instrumentation Check Valve

SAF 2507 Poppet Check Valve

25cr duplex ss Instrument Control Valve

Price of UNS S32750 Spring Check Valves depends on several factors such as pressure rating, sizes, design type and grades. It normally range between 25$ to 120$ per piece. For updated price list of Super Duplex 2507 Check Valves contact us at sales@fit-lok.com

We manufacture Super Duplex 2507 Check Valve in 2 Mm To 40 Mm Orifice Sizes or as per requirement

| Component | Material Grade/ ASTM Specification |

| Inlet body | Alloy 2507/A479 |

| Poppet | Fluorocarbon FKM-bonded alloy C-276/B574 |

| Poppet stop | Alloy C-276/B575 |

| Spring | Alloy X-750 /AMS 5699 |

| O-ring | Fluorocarbon FKM |

| Backup ring | PTFE/D1710 |

| Outlet body | Alloy 2507/A479 |

| Lubricant | PTFE-based |

We are stockist and distributor of 2507 Duplex High Pressure Check Valve in Pressure range of upto 15000 PSI

| Material | Alloy 2507 |

| Temperature, °F (°C) | |

| –10 (–23) to 100 (37) | 6000 (413) |

| 200 (93) | 5980 (412) |

| 250 (121) | 5820 (400) |

| 300 (148) | 5655 (389) |

| 350 (176) | 5555 (382) |

| 400 (204) | 5455 (375) |

| End Connections | Pressure Rating at 100°F (37°C) psig (bar) |

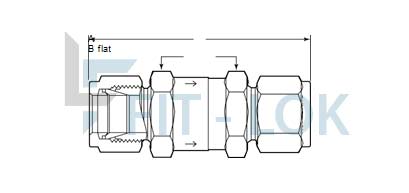

Cv | Dimensions in. (mm) |

||

| Type | Size in. | SDSS 2507 | A | B | |

| Fractional tube fitting | 1/4 | 6000 (413) | 0.67 | 2.43 (61.7) | 11/16 |

| 3/8 | 1.8 | 2.75 (69.9) | 1 1/16 | ||

| 1/2 | 6000 (413)① | 2.96 (75.2) | |||

| 3/4 | — | 4.7 | 3.52 (89.4) | 1 5/8 | |

| 1 | 3.88 (98.6) | ||||

| Female NPT | 1/4 | 6000 (413) | 0.67 | 2.13 (54.1) | 11/16 |

| 3/8 | 5300 (365) | 1.8 | 2.55 (64.8) | 1 1/16 | |

| 1/2 | 4900 (337) | 3.03 (77.0) | |||

| 3/4 | — | 4.7 | 3.23 (82.0) | 1 5/8 | |

| 1 | 3.83 (97.3) | ||||

| Male NPT | 1/4 | 6000 (413) | 0.67 | 2.17 (55.1) | 11/16 |

| 3/8 | 1.8 | 2.36 (59.9) | 1 1/16 | ||

| 1/2 | 6000 (413)① | 2.73 (69.3) | |||

| 3/4 | — | 4.7 | 3.29 (83.6) | 1 5/8 | |

| 1 | 3.67 (93.2) | ||||

| Grade | C | S | Si | P | Mo | Cr | Fe | Ni | Mn | N |

|---|---|---|---|---|---|---|---|---|---|---|

| S32750 | 0.030 max | 0.020 max | 0.80 max | 0.035 max | 3.00 – 5.00 | 24.00 – 26.00 | 58.095 min | 6.00 – 8.00 | 1.20 max | 0.24 – 0.32 |

| S32760 | 0.05 max | 0.010 max | 1.00 max | 0.030 max | 3.00 – 4.00 | 24.00 – 26.00 | 57.61 min | 6.00 – 8.00 | 1.00 max | 0.20 – 0.30 |

| Grades | Density (lb/in 3) | Density (g/cm 3) | Melting Point (°F) | Melting Point (°C) |

|---|---|---|---|---|

| S32750 / S32760 | 0.281 | 7.8 | 2460 | 1350 |

| STANDARD | UNS | WERKSTOFF NR. |

| Super Duplex 2507 | S32750 / S32760 | 1.4410 |

| Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|

| 13.5 μm/m °C (25 – 100 °C) | 77 kN/mm² | 200 kN/mm² |

| 7.5 x 10-6 in/in °F (70 – 200 °F) | 11000 ksi | 29000 ksi |

Various Destructive and Non destructive test are conducted on ASTM A276 S32750 One Way Check Valve

- Shell Test

- Fire Testing

- Cryogenic Testing

- Pneumatic Pressure Testing

- Backseat Test

- Fugitive Emissions Testing

- Seat Leak

- Hydrostatic Pressure Testing

- High-Temperature Resistance

- Corrosion and Oxidation Resistance

- High Strength

- Durability

- Compact Design

- Backflow Prevention

- Threaded Connections

- Ease of Maintenance

- Offshore Applications

- Automotive Systems

- Food and Beverage Industry

- Oil and Gas Industry

- Air and Gas Systems

- HVAC Systems

- Pharmaceutical Industries