Buy Hydraulic metering valve at best price

Top notch supplier of automatic metering valve in India

Metering valve is an instrument which regulates the flow by controlling the amount of fluid or gas passes through it. It ensures precise flow rates and pressure level. It provides adjustable timed cycle for the flow of media through valve which can be ranged between 5 to 60 seconds. Hydraulic metering valve is crucial for industries which requires precise flow of fluid whether its for dosing, dispensing or mixing liquids and gases. Due to accurate flow rate management of these valves they are widely used in critical application like food industry, health tech or oil and gas industry.

Metering ball valve are known for their high precision, efficiency, adaptability and customization. Its lightweight and compact design, low power consumption and noiseless operation makes it suitable choice in various industries. Stainless steel metering valve can deliver flow coefficients from 0.004 to 0.16.

Fit-lok is well know Metering valve manufacturer in India in different sizes and pressure rating. Our state of the art manufacturing facility make sure that Automatic metering valve tested on all the parameters before supplying it to customers. We are one of the reliable Fuel metering valve supplier in India and have exported these valves to countries like Spain, Germany and UK. We make sure that our product is high quality to meet all the international standards and have longer lifespan. If you are looking to buy high pressure metering valve please contact us as we have latest machinery and equipment and highly skilled workforce to manufacture these valves. We make sure that packaging of steam metering valve are top notch so that they did not get damaged in transportation.

Table of content

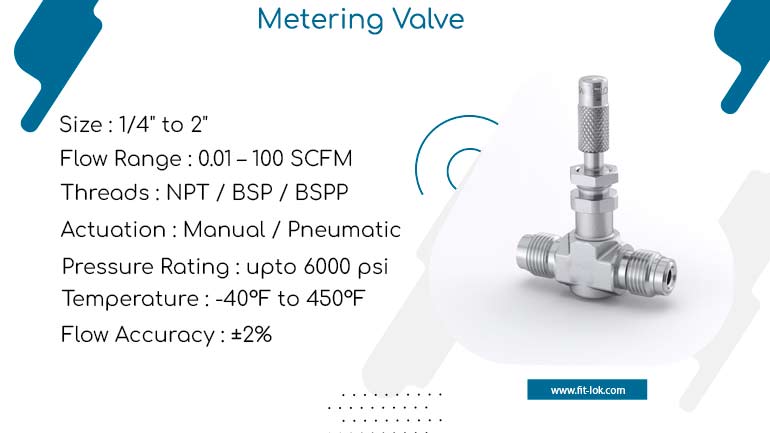

- Metering valve Specification

- Price list of hydraulic metering valve

- Different types of Metering valve

- Working principle of steam metering valve

- Fuel metering control valve Advantages

- Symbol of Gas metering valve

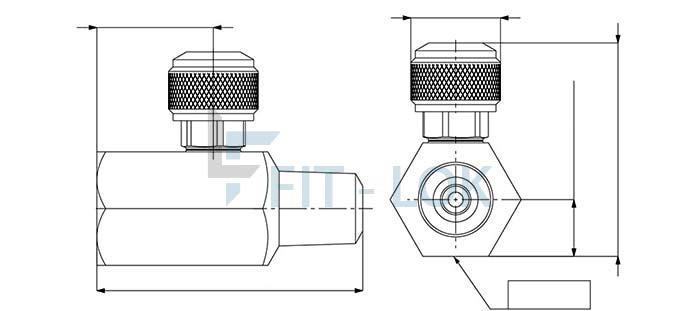

- Drawing of Metering valve with needle

- Function of metering ball valve

- Difference between Metering Valve Vs Proportioning Valve

- Fuel metering valve Applications

- Pressure-Temperature Ratings of Stainless steel metering valve

- Technical Data of low pressure metering valve

- Maximum Flow of Fuel metering valve

- High pressure metering valve O-ring material properties

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Pressure Rating |

|

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Price of High Pressure Metering Valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Metering Ball Valve you can contact us on sales@fit-lok.com

View sizes and weight chart of metering ball valve

Fuel Pump Metering Valve

High Pressure Metering Valve

Steam Metering Valve

Gas Metering Valve

Metering Ball Valve

Hydraulic Metering Valve

Fuel metering valve are used to provide accuracy and stability of flow rates

Metering valve is designed to measure mass flow of saturated and superheated steam. The sensing element of flow is the well designed and calibrated orifice plate assembly which gives differential pressure drop across the orifice plate.

- Precise Fuel Flow Regulation

- Improved Fuel Efficiency

- Enhanced Engine Performance

- Emissions Control

- Adaptability to Changing Conditions

- Reliability and Durability

- Prevents Engine Knock

Refer diagram and functions of stainless steel metering valve

- Precise Flow Control

- Adjustable Flow

- Minimal Flow Resistance

- Throttling Capability

- Versatility

| Metering Valve | Proportioning Valve |

|---|---|

| Control the flow rates of fluids for precise delivery | Controls the pressure or flow ratio of fluid between two circuits |

| Regulate amount of fluid | Maintains a fixed proportion of fluid |

| Its used for flow control | Its used for pressure control |

- Aerospace

- Automotive

- Marine Engines

- Oil and Gas Industry

- Agricultural Equipment

- Industrial Gas Turbines

| Temperature, °F (°C) | Working Pressure, psig (bar) |

| –65 (–53) to 100 (37) | 5000 (344) |

| 200 (93) | 4295 (295) |

| 300 (148) | 3875 (266) |

| 400 (204) | 3560 (245) |

| 450 (232) | 3435 (236) |

| 500 (260) | 3310 (228) |

| 600 (315) | 3130 (215) |

| 650 (343) | 3080 (212) |

| 700 (371) | 3000 (206) |

| 750 (398) | 2930 (201) |

| 800 (426) | 2880 (198) |

| 850 (454) | 2815 (193) |

| Temperature, °F (°C) | Working Pressure, psig (bar) |

| –65 (–53) to 100 (37) | 5000 (344) |

| 200 (93) | 4295 (295) |

| 300 (148) | 3875 (266) |

| 400 (204) | 3560 (245) |

| 450 (232) | 3435 (236) |

| 500 (260) | 3310 (228) |

| 600 (315) | 3130 (215) |

| 650 (343) | 3080 (212) |

| 700 (371) | 3000 (206) |

| 750 (398) | 2930 (201) |

| 800 (426) | 2880 (198) |

| 850 (454) | 2815 (193) |

| Pressure Drop to Atmosphere psi (bar) | Air Flow std ft3/min (std L/min) | Water Flow U.S. gal/min (L/min) |

| 10 (0.68) | 0.04 (1.1) | 0.01 (0.03) |

| 50 (3.4) | 0.10 (2.8) | 0.02 (0.07) |

| 100 (6.8) | 0.20 (5.6) | 0.04 (0.15) |

| O-Ring Material | Temperature Rating °F (°C) |

Body Seal Material |

| Buna N | –10 to 300 (–23 to 148) |

Standard |

| Ethylene propylene | –10 to 300 (–23 to 148) |

PTFE |

| Fluorocarbon FKM | –10 to 400 (–23 to 204) |

Standard |

| Kalrez | 0 to 300 (–17 to 148) |

PTFE |

| Neoprene | –10 to 250 (–23 to 121) |

PTFE |