View Purge control valve Sizes and Price

Leading stockist and supplier of air dryer purge valve

Purge valve is a important component of vehicle’s evaporative emission control (EVAP) system. Its used to remove excess fuel vapor from EVAP system. Purge control valve is very essential component for maintaining a vehicles performance, fuel efficiency and compliance with emissions regulations. We are one of the leading Purge valve manufacturer in India in different sizes and specification.

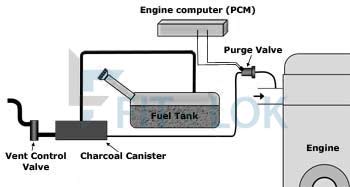

Material flow through the Vapor Canister Purge Valve is regulated by one of its two components. As a vital emission control component the Evap Purge Solenoid Valve permits the required level of fuel vapors to pass through the engine intake manifold. The computer system inside the engine operates the electrically activated Vapor Canister Purge Valve through solenoid control. Failure of the Purge Vent Valve creates a vacuum leak which impacts engine idle speed.

We specialize in manufacturing air dryer purge valve which is known for its corrosion resistance, tolerance capacity and tensile strength. We source raw materials from certified suppliers to manufacture these valves. Every valve manufactured by us are tested properly to ensure that its not leaking and closes properly. Our company produces efficient Canister Purge Valve to deliver driving satisfaction and prevent customers from frequenting mechanics for vehicle services.

Fit-Lok is supplier and exporter of N80 purge valve in Dubai, Spain, Germany and UK. These valve are tested on various parameters to ensure that they are dimensionally stable, rustproof and durable. We make sure that packaging should be top notch so that there should not be any damage in products while received by customers.

Table of content

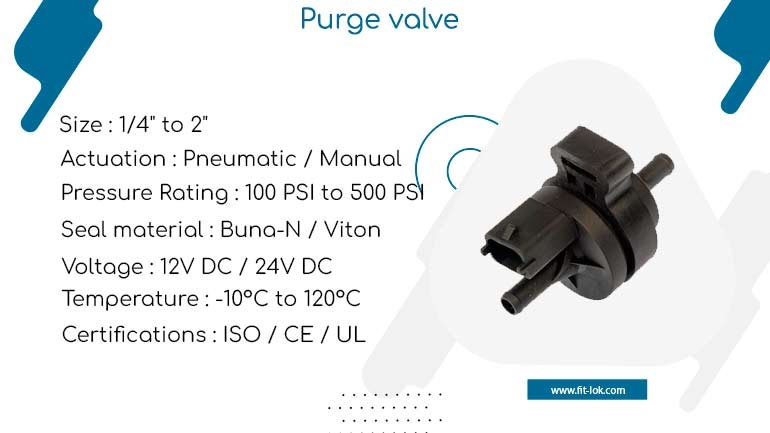

- Purge valve Specification

- Types of Purge control valve

- Price list of Air dryer purge valve

- N80 purge valve function

- Evap Purge Solenoid Valve working

- Diagram of Vapor Canister Purge Valve

- What Causes Code P0443?

- Temperature range of purge control valve

- What are the symptoms of faulty Purge Vent Valve

- Benefits of canister purge valve

| Size Range | 1/8″ TO 2″ |

| Voltage/frequancy range | 10.5 to 16.0 V/8 to 35 Hz square pulse |

| Maximum volume flow | 135 L/min @ ISO +20° C/1013 mbar |

| Low HC emission level | < 1 mg/48h |

| Filter | 70 µ mesh |

| Threads |

|

We keep ready stock Vapor Canister Purge Valve in pressure rating upto 6000 Psi

Purge Vent Valve

Evap Purge Solenoid Valve

Purge control valve

Air dryer purge valve

N80 purge valve

Vapor Canister Purge Valve

Price of Air dryer purge valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Purge control valve you can contact us on sales@fit-lok.com

- Purging Unwanted Gases or Contaminants

- Pressure Relief and Flow Control

- Safety Function

- Regulating Gas or Fluid Flow

- Gas Recovery and Efficiency

- Flow Monitoring and Regulation

- Preventing Contamination

Evap Purge Solenoid Valve can be used in application up to 4000 psig and temperature from -65 to 600°F

When the PCM sends a signal to open the valve, the valve allows the fuel vapors to flow into the engine. When the valve is closed, the fuel vapors are trapped in the evaporative canister and held until the next time the valve opens. Some purge valves also have a pressure sensor to detect when the EVAP system leaks.

Below listed problems can cause Code P0443:

- Faulty Purge Valve

- Electrical Issues

- Faulty Purge Valve Solenoid

- Bad Purge Valve Circuit

- Faulty Engine Control Module

- Vacuum Leaks

- Failed Charcoal Canister

| Temperature range | -40 up to +140° C |

|---|

Purge Vent Valve controls the flow of fuel vapors in a vehicle’s EVAP system

- Triggering the check engine light

- Poor engine performance

- Rough idle

- Reduced fuel efficiency

- Increased emissions

- Difficulty starting the engine

- Reduction of Harmful Emissions

- Improved Fuel Efficiency

- Prevention of Fuel Tank Overpressure

- Enhanced Vehicle Performance

- Helps Pass Emissions Inspections

- Longer Lifespan of the EVAP System

- Improved Environmental Impact