Biggest Instrument Air Header Manufacturer in India

An instrument air header is defined as pressurized air that supplies a number of instruments, control valves, and other appliances within an industrial plant. These headers are customarily applied in the oil and gas, petrochemicals, and power production and many other sectors in which precise control is mandatory. It contains apart from cleaning and drying compressed air, regulating of compressed air that will enable correct working of the instruments and devices in the header.

In particular, it is necessary to indicate that instrument air headers are supposed to withstand pressure. They are usually stamped for pressure ranges of 150psi-1000 psi or according to the design requirements. However, it is required that the pressure rating of the instrument air header is able to address the requirements of the devices and systems that are to be supplied with compressed air by the instrument air header. Instrument air headers are standard as well as customizable depending on the flow rate and pressure needed. The size of the instrument air header must be determined, therefore, by the peak flow rate and absolute pressure that will be required to serve the devices and systems supplied with instrument air.

We keep ready stock of Compressed Air Header

Among the main advantages of instrument air headers is that it offers you a constant and consistent supply of compressed air for your operations. This serves to make sure that your tools as well as machinery are well maintained enabling them achieve their greatest levels of productivity thus producing minimal output. The compressed air created by instrument air headers can be employed to operate diverse apparatus including pneumatic tools, actuators, valves and control systems.

Table of content

- Specification of Air Header

- Compressed Air Header types

- Advantage Of Air compressor header

- How to choose Air header

- Max allowable pressure and temperature of compressed air header

- Properties of Instrument air headers

- Benefits of air compressor header

- Pneumatic air header application

- What is the use of instrument air header

| BODY SIZE | 1″ NB TO 4″ NB |

| SCHEDULE | SCH 40, SCH 80, SCH 160, SCH XXS |

| LENGTH | 8″ OR LARGER |

| NO. OF OUTLET PORTS | 2 WAYS TO 20 WAYS |

| VALVE TYPE | BALL VALVE & NEEDLE VALVE |

| VALVE END CONNECTION | FEMALE THREADED, MALE THREADED, TUBE END |

| CONNECTION SIZE | UPTO 1/2″ |

| INLET & OUTLET CONNECTION | BALL VALVE, NEEDLE VALVE, FLANGED |

| WORKING PRESSURE | UPTO 10,000 PSI |

| THREADS | NPT, BSPP, BSPT |

| SEALS | PTFE, GRAPHITE, PEEK |

| BODY TYPE | SEAMLESS PIPE, BAR STOCK |

| OPTIONS | MOUNTING BRACKET |

| MATERIAL | SS 316, SS 304, SS 316 TI, COPPER, BRASS, DUPLEX, CS, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L, TITANIUM & ALL OTHER ALLOYS |

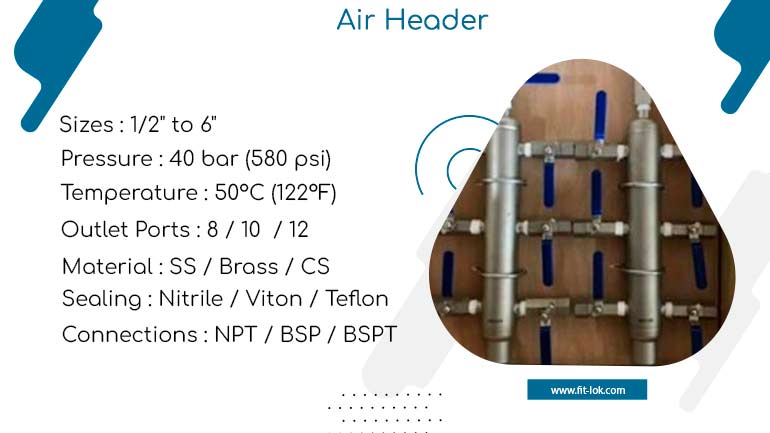

Air Header

Instrument Air Header

Compressed Air Header

- Every Air Header is factory tested

- Multiple Valve inlets and Outlets save on Cost

- Customized Compact design

- Variety of end connections

- Pipe size

- Pipe length

- Pipe diameter

- Air pressure

- Air flow

- Air headers

| Max. allowable Pressure | Max. allowable Temperature |

| 40 bar (580 psi) | 50°C (122°F) |

- Size

- Pressure rating

- Material

- Fittings and connections

- Quality of air

- Increased Efficiency

- Enhanced Safety

- Improved Process Control

- Reduced Maintenance

- Cost Savings

- Pneumatic tools

- HVAC System

- Industries processes

- Food and Beverage Processing

- Safety control

- Power Generation Industry

- Petrochemical Industry

It is utilized in safety valve and emergency shutdown systems, together with guaranteeing that instruments and valves maintain their optimal state.

- Reliable air supply

- Pressure regulation

- Air distribution

- Instrument accuracy