Carpenter 20 Hydraulic Check Valve manufacturer in India in size range of 1/2″ to 2″

Nickel alloy 20 Inline Check Valve comes in Threaded, socket weld and Flange End Connection

Alloy 20 Check Valve are normally contain nickel, chromium and molybdenum and widely used in an applications which contains sulfuric acid. Carpenter 20 Hydraulic Check Valve typically have a valve body, a seat, and disc or ball which closes valve opening and prevent the fluid to reverse. Fit-Lok is biggest Alloy 20 Check Valve manufacturer in India which are designed to withstand high pressure and temperature conditions.

We are one of the leading Nickel alloy 20 Inline Check Valve supplier in India and these valves are comply with API 602 and BS 5352 manufacturing standards. UNS N08020 Spring Check Valve comes in different connections type such as socket weld, threaded and flanged in size range of 1/2″ to 4″. These valves are mainly used to prevent accidents caused by sudden power loss in piping system. WERKSTOFF NR. 2.4660 Poppet check valve has a good tensile strength, it also can be welded using standard technique.

We are one of the biggest stockist and supplier of Nickel Alloy 20 Piston Check Valve in India, We manufacture and supply these valves worldwide including Spain, Germany, Algeria and UAE. Carpenter 20 Check Valve are available in large range of sizes, pressure rating and dimensions. We have ready stock of these valves which can be dispatch within a day for urgent requirements. As a Carpenter 20 inline Check Valve manufacturer we source raw material from certified suppliers only. We make sure that these valves passed all the destructive and non destructive testing to use in real world.

Table of content

- Alloy 20 Check Valve specification

- Carpenter 20 check valve types

- Manufacturing standards of UNS N08020 Spring Check Valve

- Price list of Alloy 20 Check Valve

- Flow rate of Nickel Alloy 20 Piston Check Valve

- Dimensions of Alloy 20 Check Valve

- Carpenter 20 Male to Female Check Valves dimensions

- DIN 2.4660 Control Check Valve Chemical composition

- UNS N08020 Instrumenation check valve mechanical properties

- Carpenter 20 inline Check Valve equivalent grade

- Alloy 20 Instrument Air Check Valve Applications

- Different seat materials of CN7M Spring Check Valves

- Testing inspections of Alloy 20 Non Return Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

We are leading exporter of UNS N08020 Spring Check Valve and can deliver it within 7 to 30 days based on location

Alloy 20 Hydraulic Check Valve

Carpenter 20 Inline Check Valve

UNS N08020 Nrv Valve

Nickel Alloy 20 Instrument Air Check Valve

WNR 2.4660 Non Return Valve

Alloy 20 Spring Check Valve

UNS N08020 Instrumentation Check Valve

Carpenter 20 Poppet Check Valve

DIN 2.4660 Instrument Control Valve

- ASME B16.34

- BS 1868

- MSS SP-55

- ASME B16.5

- API 6D / API 598

- ASME B16.10

- MSS SP-25

Price of UNS N08020 Spring Check Valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Carpenter 20 Male to Female Check Valves you can contact us on sales@fit-lok.com

| Flow rate | 1.49 gpm |

|---|

We stock WERKSTOFF NR. 2.4660 Poppet check valve in wide range of sizes, Contact us to get a quote

| Inlet End Connection | L (mm) | A/F (mm) | |

|---|---|---|---|

| Inlet | Outlet | ||

| 1/8″ | 1/8″ | 69 | 19.0 |

| 1/4″ | 1/4″ | 72 | 19.0 |

| 3/8″ | 3/8″ | 74 | 19.0 |

| 1/2″ | 1/2″ | 79 | 22.0 |

| 3/4″ | 3/4″ | 106 | 32.0 |

| 1″ | 1″ | 118 | 35.0 |

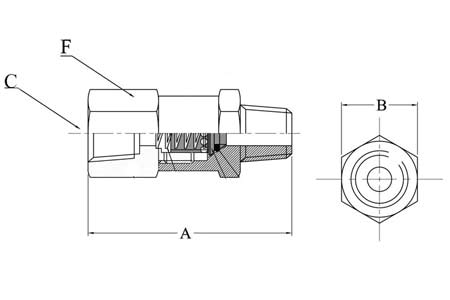

| A | B (A/F) | C | F (A/F) |

| 62 | 19 | 1/8″ | 19 |

| 62 | 19 | 1/4″ | 19 |

| 62 | 22 | 3/8″ | 22 |

| 75 | 28.5 | 1/2″ | 28.5 |

| 78 | 32 | 3/4″ | 32 |

| 90 | 41 | 1″ | 41 |

| Ni | C | Mn | P | Cr | Si | Nb | Mo | S | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 32 – 38 | 0.02 max | 1 – 2 | 0.02 max | 19 – 21 | 0.7 max | 0.1 – 0.3 | 2 – 3 | 0.005 max | 3 – 4 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Elongation | Tensile Strength |

|---|---|---|---|---|

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35,000, MPa – 241 | 30 % | Psi -80,000, MPa -551 |

| WERKSTOFF NR. | EN | AFNOR | UNS |

|---|---|---|---|

| 2.4660 | NiCr20CuMo | Z2NCUD31-20AZ | N08020 |

Nickel Alloy 20 Piston Check Valve are widely used in high concentrations of sulfuric acid applications

- Oil and Gas Industry

- Food and Beverage Industry

- HVAC Systems

- Pharmaceutical Industries

- Air and Gas Systems

- Offshore Applications

- Automotive Systems

- PEEK

- Virgin PTFE

- Shell Test

- Backseat Test

- Seat Leak

- Fugitive Emissions Testing

- Pneumatic Pressure Testing

- Fire Testing

- Cryogenic Testing

- Hydrostatic Pressure Testing