We are ASME SA 269 TP 316 Seamless Tubing Supplier in India

Our SA269 Tubing are manufactured using high-grade material, ensuring excellent corrosion resistance and durability.

Table of content

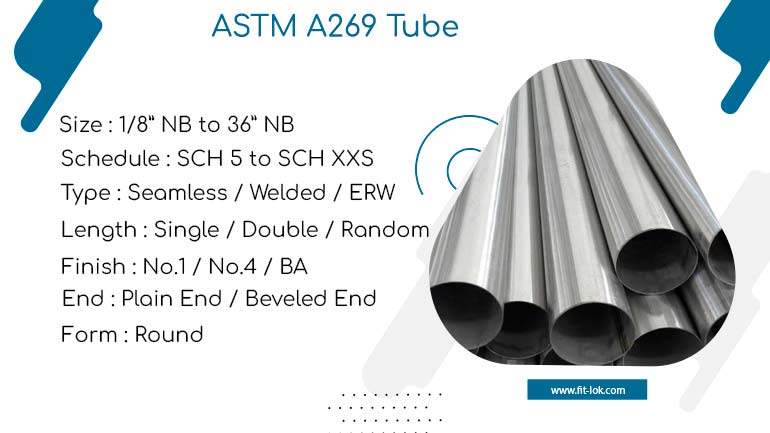

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

View Schedule Chart and updated price list of ASME SA269 Tubes

ASME SA 269 TP 316 Seamless Tubing

ASME SA269 Tubes

ASTM A269 Seamless Tubing

ASTM A269 SS Tubing

ASME SA 269 Seamless Tube

ASTM A269 Standard Tubing

ASTM A269 Seamless Tubing manufacturer in Mumbai

| Grade | Carbon | Nickel | Manganese | Sulfur | Silicon | Phosphorus | Chromium | Niobium | Molybdenum | Titanium |

|---|---|---|---|---|---|---|---|---|---|---|

| TP321 | 0.08 | 9.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 17.0-19.0 | 5C -0.70 | ||

| TP304 | 0.08 | 8.0-11.0 | 2.00 | 0.030 | 1.00 | 0.045 | 18.0-20.0 | |||

| TP316 | 0.08 | 10.0-14.0 | 2.00 | 0.030 | 1.00 | 0.045 | 16.0-18.0 | 2.00-3.00 | ||

| TP304L | 0.035 | 8.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 18.0-20.0 | |||

| TP316L | 0.035 D | 10.0-15.0 | 2.00 | 0.030 | 1.00 | 0.045 | 16.0-18.0 | 2.00-3.00 | ||

| TP347 | 0.08 | 9.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 17.0-19.0 | 10C -1.10 |

| Grade | Temperure F (C) | Heat treatment | Hardness | |

|---|---|---|---|---|

| Brinell | Rockwell | |||

| TP304 | 1900 (1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP304L | 1900 (1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP316 | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP316L | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP321 | 1900(1040) F | Solution | 192HBW/ 200HV | 90HRB |

| TP347 | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| SAE grade | EN-standard Steel name |

UNS | EN-standard |

|---|---|---|---|

| 409 | X6CrTi12 | S40900 | 1.4512 |

| 410 | S41000 | ||

| 301 | X10CrNi18-8 | S30100 | 1.4310 |

| 301LN | X2CrNiN18-7 | 1.4318 | |

| 304L | X2CrNi18-9 | S3043 | 1.4307 |

| 316 | G-X 6 CrNiMo 18-10 | S31600 | 1.4408 |

| 304L | X2CrNi19-11 | S30403 | 1.4306 |

| 304LN | X2CrNiN18-10 | S30453 | 1.4311 |

| 310 | X22CrNi2520 | S31000 | 1.4841 |

| 304 | X5CrNi18-10 | S30400 | 1.4301 |

| 304H | X6CrNi18-11 | S30409 | 1.4948 |

| 316LN | X2CrNiMoN17-12-2 | S31653 | 1.4406 |

| 305 | X5CrNi18-12 | S30500 | 1.4303 |

| 312 | X5CrNi30-9 | ||

| 310S | X 5 CrNi 2520 | S31008 | 1.4845 |

| 321 | X6CrNiTi18-10 | S32100 | 1.4541 |

| 316 | X3CrNiMo17-13-3 | S31600 | 1.4436 |

| 321H | X12CrNiTi18-9 | S32109 | 1.4878 |

| 2304 | X2CrNi23-4 | S32304 | 1.4362 |

| 316L | X2CrNiMo17-12-2 | S31603 | 1.4404 |

| 316 | X5CrNiMo17-12-2 | S31600 | 1.4401 |

| 316L | X2CrNiMo17-12-3 | S31603 | 1.4432 |

| 316L | X2CrNiMo18-14-3 | S31603 | 1.4435 |

| 316Ti | X6CrNiMoTi17-12-2 | S31635 | 1.4571 |

| 316LN | X2CrNiMoN17-13-3 | S31653 | 1.4429 |

| 317L | X2CrNiMo18-15-4 | S31703 | 1.4438 |

| 2205 | X2CrNiMoN22-5-3 | S31803/S32205 | 1.4462 |

| J405 | X2CrNiMoCuWN25-7-4 | S32760 | 1.4501 |

| 904L | X1NiCrMoCu25-20-5 | N08904 | 1.4539 |

| X1NiCrMoCuN25-20-7 | N08926 | 1.4529 | |

| 254SMO | X1CrNiMoCuN20-18-7 | S31254 | 1.4547 |

For reliable and superior-grade high-temperature ASTM A269 SS Tubing, our leading stockist and distributor services are unmatched.

| Nominal Pipe Size | Tolerance, % | |

|---|---|---|

| + | – | |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

Application of ASTM A269 SS Tubing

- Water treatment

- HVAC systems

- Automotive applications

- Aerospace industry

- Marine applications

Packaging of ASME SA 269 Seamless Tube

Packaging methods for steel pipe would vary depending on the type and size of the tubes. We will provide the packaging methods applied for the most common types of piping,but additional packaging precautions should be taken in some cases to prevent damages mainly caused by the wiggling and bending during the sealift handing and transportation stages and process.

Frequently asked questions

What is ASTM A269?

ASTM A269 is a standard specification for seamless and welded stainless steel tubes

What are the common grades of stainless steel used in ASME SA269 Tubes?

Common grades of stainless steel used in ASME SA269 Tubes include 304, 304L, 316, and 316L, among others.

What are the available sizes and dimensions of ASTM A269 Seamless Tubing?

ASTM A269 Seamless Tubing are available in various sizes and dimensions, ranging from small to large diameters, with specific wall thicknesses as per the standard.

What are the specific requirements for surface finish and tolerances in ASTM A269 SS Tubing?

ASTM A269 SS Tubing have specific requirements for surface finish, including options such as annealed and pickled, bright annealed, or polished finishes, and tight tolerances for dimensions and mechanical properties.

What are the typical applications for ASME SA 269 Seamless Tube in industries such as pharmaceutical, food processing, and chemical processing?

ASME SA 269 Seamless Tube find typical applications in industries such as pharmaceutical, food processing, and chemical processing, where high-quality, corrosion-resistant stainless steel tubes are required for sanitary and fluid transfer applications.