Biggest ASME SA270 Polished Dairy Tube Supplier in India

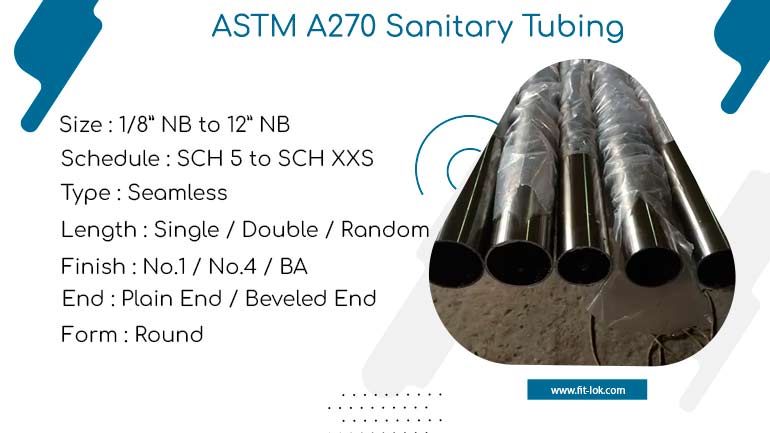

The Stainless Steel Sanitary Tube is a sanitary grade of stainless steel tubing that comes in both welded and seamless forms. ASTM A270 Sanitary Tubing solutions are used in the dairy and food industries, as well as bio processing equipment, and have a particular surface treatment. All of these tubes have been hot-treated. The ASTM A270 standard is used for manufacturing BPE Stainless Steel Tubing solutions.

These tubes are typically constructed from cold-rolled stainless steel strips. Their chemical ingredients are carefully managed to improve weldability. ASME BPE Pipe is also bright annealed in a controlled environment to provide optimal structural integrity.

Don’t forget to check A270 Stainless Steel Tubing Dimensions and Weight Chart

The ASTM A270 Tubing solution is finished in 180, 240, or 320 grit. 180 is a fine grit that aids in the removal of scratches left by coarser grits. The 240 grit also aids in the removal of surface imperfections on metals such as stainless steel. The 320 grit is a very fine grit that is used for gentle sanding.

ASTM A270 tubes are made of acid-resistant austenitic stainless steel. It has been cold worked to achieve a minimum tensile strength of 700 MPa. Sanitary Stainless Steel Tubing Supplier primarily serves the dairy industry with 3A tubing. 3A tubes are sanitary and can be used in food processing equipment.

Sanitary Stainless Steel Tubing Supplier mechanically polishes the surface with various abrasives. Electropolishing on 316 Stainless Steel Sanitary Tubing, on the other hand, employs chemicals and electricity to dissolve the surface. Inclusions cannot be removed by mechanical polish, however electropolish makes the surface featureless.

Table of content

| Specification | ASTM A270 / ASME SA 270 |

| Outer Diameter | 1/2 Inch |

| Wall Thickness | 16 Gauge (0.065 Inch) |

| Length | 20 Inch |

| Polish | Mechanical Polished |

| Type | Seamless |

| Finish | 20Ra Inner Diameter/ 32Ra Outer Diameter |

| Grades | SS 304, SS 304L,SS 316,SS 316L |

| Outer Diameter Tolerance | +/-0.005” / +/-0.13MM |

| Wall Thickness Tolerance | +/-10% |

| Mill Test Certificate | EN10204 3.1 |

| Certification | 3A – Food / Dairy Grade |

| Length Tolerance | +1/8” / +3.18MM |

| Standard | 3A / ASTM A270 / A270M |

A270 Stainless Steel Tubing

ASTM A270 Tp316l

ASTM A270 Tp304

A270 Sanitary Tubing

A270 Polished Dairy Tube

ASTM A270 Tubing

Benefit from competitive rates on top-grade A270 Sanitary Tubing supplied by trusted vendors in India

| Finish Code | Contact Surface Finish Treatment (ID) | Contact Surface (Max Ra)* | Non-Product Contact Surface (Max Ra) |

|---|---|---|---|

| -PM | Electropolished | 15 µ-inch(0.38 µm) | 32 µ-inch(0.81 µm) |

| -PL | Mechanical Polish | 20 µ-inch(0.51 µm) | 32 µ-inch(0.81 µm) |

- Size: 1/2″ – 8″

- WT: .019″ – .145″

- Lengths: 1″ – 60′

We take pride in being the leading stockist and distributor, ensuring prompt availability of high-temperature A270 Polished Dairy Tube.

| Size Outer Diameter | Wall Thickness | Length Tolerance | Outside Diameter Tolerance | Wall Thickness Tolerance | ||||

|---|---|---|---|---|---|---|---|---|

| mm | Inch | mm | Inch | mm | Inch | mm | Inch | () |

| 50.8 | 2 | 1.65 | 0.065 | 3.18 | ⅛ | 0.20 | 0.008 | 10.0 |

| 19.1 | ¾ | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 38.1 | 1½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.20 | 0.008 | 10.0 |

| 12.7 | ½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 63.5 | 2½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.25 | 0.010 | 10.0 |

| 25.4 | 1 | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 76.2 | 3 | 1.65 | 0.065 | 3.18 | ⅛ | 0.25 | 0.010 | 10.0 |

| 101.6 | 4 | 2.11 | 0.083 | 3.18 | ⅛ | 0.38 | 0.015 | 10.0 |

| 152.4 | 6 | 2.77 | 0.109 | 25.4 | 1 | 0.76 | 0.030 | 10.0 |

| Nominal Pipe Size in Inch | Schedule 40 | Schedule 10 | ||

|---|---|---|---|---|

| 304L | 316L | 304L | 316L | |

| 1/2 | A312P4-4050 | A312P4-6050 | A312P1-4050 | A312P1-6050 |

| 3/4 | A312P4-4075 | A312P4-6075 | A312P1-4075 | A312P1-6075 |

| 1 | A312P4-4100 | A312P4-6100 | A312P1-4100 | A312P1-6100 |

| 1-1/4 | A312P4-4125 | A312P4-6125 | A312P1-4125 | A312P1-6125 |

| 1-1/2 | A312P4-4150 | A312P4-6150 | A312P1-4150 | A312P1-6150 |

| 2 | A312P4-4200 | A312P4-6200 | A312P1-4200 | A312P1-6200 |

| 2-1/2 | A312P4-4250 | A312P4-6250 | A312P1-4250 | A312P1-6250 |

| 3 | A312P4-4300 | A312P4-6300 | A312P1-4300 | A312P1-6300 |

| 4 | A312P4-4400 | A312P4-6400 | A312P1-4400 | A312P1-6400 |

| 6 | A312P4-4600 | A312P4-6600 | A312P1-4600 | A312P1-6600 |

| 8 | A312P4-4800 | A312P4-6800 | A312P1-4800 | A312P1-6800 |

| 10 | A312P4-41000 | A312P4-61000 | A312P1-41000 | A312P1-61000 |

| 12 | A312P4-41200 | A312P4-61200 | A312P1-41200 | A312P1-61200 |

| Outer diameter in Inch | Dimensions | ||

| Wall Thickness | Inner Diameter | Gauge | |

| 1 | 0.065 | 0.870 | 16 |

| 2 | 0.065 | 1.870 | 16 |

| 4 | 0.065 | 3.870 | 16 |

| 3 | 0.120 | 2.760 | 11 |

| 2 | 0.120 | 1.760 | 11 |

| 2-1/2 | 0.065 | 2.370 | 16 |

| 1/2 | 0.065 | 0.370 | 16 |

| 3 | 0.065 | 2.870 | 16 |

| 4 | 0.083 | 3.834 | 14 |

| 1-1/2 | 0.065 | 1.370 | 16 |

| 6 | 0.083 | 5.834 | 14 |

| 3/4 | 0.065 | 0.620 | 16 |

| 6 | 0.109 | 5.782 | 12 |

| 8 | 0.109 | 7.782 | 12 |

| 10 | 0.109 | 9.782 | 12 |

| 5 | 0.083 | 4.834 | 14 |

| 12 | 0.109 | 11.782 | 12 |

Cost-effective ASTM A270 Tubing from trusted suppliers in India

| Elements | Composition |

|---|---|

| Phosphorus | 0.045 |

| Sulphur | 0.030 |

| Sulphur | 0.005-.017 |

| Silicon | 0.750 |

| Manganese | 2.000 |

| Nickel | 10.0-14.0 |

| Carbon | 0.030 |

| Chromium | 16.0-18.0 |

| Molybdenum | 2.0-3.0 |

Application of Astm A270 Tubing

- Marine applications

- Aerospace industry

- Water treatment

- Automotive applications

- HVAC systems

Packaging of ASTM A270 TP 304 Seamless Tube

The packaging approach for steel tubes is tailored to each pipe’s type and dimensions. Our packaging methods cater to the standard pipe types, but added precautions are advised during sealift handling and transportation to prevent damages related to movement and bending.

Frequently asked questions

What is ASTM A270 and how does it define the specifications for sanitary tubing?

ASTM A270 is a standard specification for seamless and welded austenitic stainless steel sanitary tubing, providing requirements for dimensions, surface finish, and material properties.

What are the common materials used in A270 Stainless Steel Tubing?

Common materials used in A270 Stainless Steel Tubing include stainless steel grades such as 304, 304L, 316, and 316L.

What are the surface finish requirements specified by ASTM A270 for sanitary tubing?

ASTM A270 specifies various surface finishes for sanitary tubing, including mechanically polished, electropolished, and unpolished options.

What are the dimensional tolerances and mechanical properties outlined in ASTM A270 for sanitary tubing?

ASTM A270 sets dimensional tolerances and mechanical properties for sanitary tubing, ensuring precise dimensions and appropriate strength and corrosion resistance.

How does ASME SA270 ensure the hygienic and sanitary properties of tubing used in industries such as food, beverage, and pharmaceutical?

ASME SA270 ensures the hygienic and sanitary properties of tubing used in industries like food, beverage, and pharmaceutical by setting strict standards for cleanliness, smoothness, and compatibility with cleaning and sterilization processes.