Are you looking for A511M Grade Mt304 Mechanical Tube Supplier in India

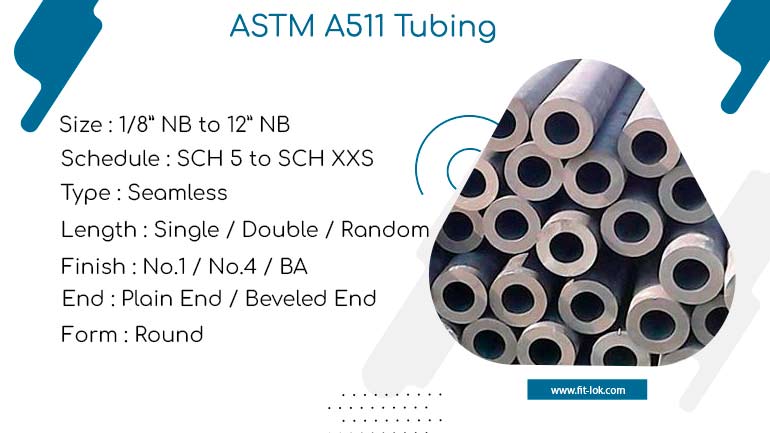

ASTM A511 tube is designed for mechanical applications that require excellent corrosion resistance. The seamless ASTM A511 stainless steel tube has improved dimensional precision. This tube collection contains a variety of material grades. Different forms of tube, such as ASTM A511 Seamless Stainless Steel Mechanical tube and Hollow Bar, are also employed in various applications. The material grades include MT 302, 303, 304, 305, and 347. Manganese, phosphorus, sulphur, silicon, nickel, and chromium are all present in the composition of these grades.

Buy ASTM A511 Mt316 Stainless Steel Tube at low cost

Some ASTM A511 Seamless tube grades also contain molybdenum, titanium, and columbium in varying amounts. Selenium is present in the grade MT303se. The ASTM A511 MT304 is the most commonly used because it is cost effective, has strong strength, and has a long life. When compared to other grades, such as 316, the material’s corrosion resistance is low. According to the custom specifications, the ASTM A511 grade mt304 tubes can range in size from 12 inches to 24 inches and higher. The length of the tubes vary according to requirements and application type. ASTM A511 mt316 is an austenitic stainless steel with chromium, nickel, and molybdenum. It has greater resistance to chloride iron stress corrosion cracking.

As a result, these tubes are preferred in applications such as marine, sea water, food processing, wastewater management, pollution control, and brackish water.

Table of content

| Specifications | ASTM A511/ ASME SA511 | |

| Range | 6NB to 1200NB IN | |

| Size | OD from ¼’’ to 12 3/4’’ | |

| Wall Thickness | 0.02’’ to 1’’ (0.5 mm to 25.4 mm) | |

| Schedule | SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS. |

As the premier stockist and distributor, we offer a comprehensive range of high-temperature Cold Finished ASTM A511 Tubing.

|

Largest Specified

Outside Dimension, Inches |

Wall Thickness,

Inches |

OD

± Inches |

|

To 1-1/4

|

all

|

0.015

|

|

Over 1-1/4 to 2

|

all

|

0.020

|

|

Over 2-1/2 to 5

|

all

|

0.030

|

|

Over 5-1/2

|

all

|

0.060

|

| Grade | Composition, % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbon | Manganese, max | Phosphorus,

max |

Sulfur,

max |

Silicon, max | Nickel | Chromium | Molybdenum | Titanium | Columbium plus Tantalum | Selenium | |

| A511 Seamless Mechanical Tubing MT 302 | 0.08 to 0.20 | 2.00 | 0.040 | 0.030 | 1.00 | 8.0–10.0 | 17.0–19.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 303 | 0.15 max | 2.00 | 0.20 | 0.15 min | 1.00 | 8.0–10.0 | 17.0–19.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 303Se | 0.15 max | 2.00 | 0.040 | 0.040 | 1.00 | 8.0–11.0 | 17.0–19.0 | … | … | … | 0.12–0.2 |

| A511 Seamless Mechanical Tubing MT 304 | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 8.0–11.0 | 18.0–20.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 304L | 0.035 maxA | 2.00 | 0.040 | 0.030 | 1.00 | 8.0–13.0 | 18.0–20.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 305 | 0.12 | 2.00 | 0.040 | 0.030 | 1.00 | 10.0–13.0 | 17.0–19.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 309S | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 12.0–15.0 | 22.0–24.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 310S | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 19.0–22.0 | 24.0–26.0 | … | … | … | … |

| A511 Seamless Mechanical Tubing MT 316 | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 11.0–14.0 | 16.0–18.0 | 2.0–3.0 | … | … | … |

| A511 Seamless Mechanical Tubing MT 316L | 0.035 maxA | 2.00 | 0.040 | 0.030 | 1.00 | 10.0–15.0 | 16.0–18.0 | 2.0–3.0 | … | … | … |

| A511 Seamless Mechanical Tubing MT 317 | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 11.0–14.0 | 18.0–20.0 | 3.0–4.0 | … | … | … |

| A511 Seamless Mechanical Tubing MT 321 | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 9.0–13.0 | 17.0–20.0 | … | B | … | … |

| A511 Seamless Mechanical Tubing MT 347 | 0.08 max | 2.00 | 0.040 | 0.030 | 1.00 | 9.0–13.0 | 17.0–20.0 | … | … | C | … |

Supplier And Exporter Of MT310S large diameter ss tube

| Tensile | Yield | Elon- | |

| Grade | Strength, | Strength | gationB in 2 |

| min, | min, | in., or [50 | |

| ksi [MPa] | ksi [MPa] | mm] min., | |

| % | |||

| All austenitic steelsC | 75 [515] | 30 [210] | 35 |

| MT 403 | 60 [415] | 30 [210] | 20 |

| MT 405 | 60 [415] | 30 [210] | 20 |

| MT 410 | 60 [415] | 30 [210] | 20 |

| MT 414 | 100 [690] | 65 [450] | 15 |

| MT 416 Se | 60 [415] | 35 [240] | 20 |

| MT 429/MT 430 | 60 [415] | 35 [240] | 20 |

| MT 431 | 105 [725] | 90 [620] | 20 |

| MT 440 A | 95 [655] | 55 [380] | 15 |

| MT 443 | 70 [485] | 40 [275] | 20 |

| MT 446–1 | 70 [485] | 40 [275] | 18 |

| MT 446–2 | 65 [450] | 40 [275] | 20 |

| 29-4 | 70 [485] | 55 [380] | 20 |

| 29-4-2 | 70 [485] | 55 [380] | 20 |

| S31260 | 100 [690] | 65 [450] | 25 |

| S31803 | 90 [620] | 65 [450] | 25 |

| S32101 | |||

| Wall # 0.187 in. [5.00 mm] | 101 [700] | 77 [530] | 30 |

| Wall > 0.187 in. [5.00 mm] | 94 [650] | 65 [450] | 30 |

| S32205 | 95 [655] | 70 [485] | 25 |

| S32304 | |||

| OD 1 in. [25 mm] and Under | 100 [690] | 65 [450] | 25 |

| OD Over 1 in. [25 mm] | 87 [600] | 58 [400] | 25 |

| S32506 | 90 [620] | 65 [450] | 18 |

| S32550 | 110 [760] | 80 [550] | 15 |

| S32707 | 133 [920] | 101 [700] | 25 |

| S32750 | 116 [800] | 80 [550] | 15 |

| S32760 | 109 [750] | 80 [550] | 25 |

| S32808 | 116 [800] | 80 [550] | 15 |

| S32906 | |||

| Wall below 0.40 in. [10 mm] | 116 [800] | 94 [650] | 25 |

| Wall 0.40 in. [10 mm] | 109 [750] | 80 [550] | 25 |

| and above | |||

| S32950 | 100 [690] | 70 [480] | 20 |

| S39274 | 116 [800] | 80 [550] | 15 |

| N08020 | 80 [550] | 35 [240] | 30 |

| N08367 | |||

| #3⁄16 in. [4.8 mm] wall | 100 [690] | 45 [310] | 30 |

| >3⁄16 in. [4.8 mm] wall | 95 [655] | 45 [310] | 30 |

| N08800 | |||

| cold worked annealed | 75 [515] | 30 [205] | 30 |

| hot-finished annealed | 65 [450] | 25 [170] | 30 |

| N08810 | 65 [450] | 25 [170] | 30 |

| N08811 | 65 [450] | 25 [170] | 30 |

| N08904 | 71 [490] | 31 [215] | 35 |

| N08925 | 87 [600] | 43 [295] | 40 |

| N08926 | 94 [650] | 43 [295] | 35 |

Check properties and weight chart of ASTM A511 Hollow bar

| Grade | Temperature °F [°C] |

| N08020 | 1700–1850 [925–1010]A,B |

| N08367 | 2025 [1105]A |

| N08810 | 2050 [1120]A |

| N08811 | 2100 [1150]A |

| N08904 | 2000 [1100]A |

| N08925 | 2010–2100 [1100–1150]A |

| N08926 | 2010–2100 [1100–1150]A |

| S31260 | 1870-2010 [1020-1100] |

| S31803 | 1870-2010 [1020-1100] |

| S32101 | 1870 [1020] min |

| S32205 | 1870-2010 [1020-1100] |

| S32304 | 1700-1920 [925-1050] |

| S32506 | 1870-2050 [1020-1120] |

| S32550 | 1900 [1040] min |

| S32707 | 1975-2050 [1080-1120] |

| S32750 | 1880-2060 [1025-1125] |

| S32760 | 1960-2085 [1070-1140] |

| S32808 | 1920-2100[1050-1150] |

| S32906 | 1870-2100[1020-1150] |

| S32950 | 1820-1880[990-1025] |

| S39274 | 1880-2060[1025-1125] |

A511M Grade Mt304 Mechanical Tube

ASTM A511 Seamless tube

ASTM A511 grade mt304

ASTM A511 Mt316 Stainless Steel Tube

Cold Finished ASTM A511 Tubing

MT310S large diameter ss tube

Application of A511M Grade Mt304 Mechanical Tube

- Aerospace industry

- Marine applications

- Water treatment

- HVAC systems

- Automotive applications

Packaging of ASTM A511 tubing

Customized packaging methods are implemented for steel tubes, taking into account their varying types and sizes. While we ensure proper packaging for typical pipe types, special attention is required during sealift handling and transportation to minimize potential harm due to movement and bending.

Frequently asked questions

What is the typical material specification covered by ASTM A511 for stainless steel mechanical tubing?

ASTM A511 covers stainless steel mechanical tubing made from various grades, including austenitic, ferritic, and duplex stainless steels.

Is A511M Grade Mt304 Mechanical Tube available in seamless or welded form?

A511M Grade Mt304 Mechanical Tube is available in both seamless and welded forms, providing flexibility in choosing the appropriate manufacturing method for specific application requirements.

What are the common applications of ASTM A511 tubing?

ASTM A511 tubing finds applications in industries such as automotive, construction, aerospace, and manufacturing, where precise dimensional accuracy and high mechanical strength are crucial.

Does ASTM A511 specify any additional requirements for surface finish and appearance?

Yes, ASTM A511 specifies requirements for surface finish, including options such as annealed and pickled, bright annealed, or polished finishes, enhancing the aesthetics and corrosion resistance of the tubing.