SA554 Grade Mt304 mechanical tubing supplier in India

ASTM A554 stainless steel mechanical tube meets specified standards. The ASTM A554 tube has an excellent chemical composition of carbon, manganese, phosphorus, sulphur, silicon, chromium, and nickel. These tubes are more resistant to corrosive and oxidative conditions due to the composition. The mechanical qualities of SA554 Stainless Steel Tubing are outstanding. These tubes can be lengthened by 35% in the system and have a minimum tensile strength of 75ksi and a minimum yield strength of 30ksi. The tubes might be square or rectangular in shape. The ASME SA554 SS Square Tubing is passed through dies before being welded in place. This tubing can also be manufactured in seamless versions.

A554 Grade Mt 316L Rectangular Tube has moderate strength with excellent cold formability and weldability.

This tubing can also be manufactured in seamless versions. They are intended for usage in high-temperature and high-pressure environments. SA554 SS Rectangular Tubes feature increased stability and uneven rectangular cross sections. These tubes are extremely robust and are available in a variety of diameters to satisfy product specifications. ASTM A554 Ornamental Tubes is a gleaming and aesthetically pleasing quality with exceptional strength and durability. These tubes are an excellent replacement for traditional products in a variety of applications. They are a prevalent feature of steel grades 304 and 316.

The ASTM A554 Welded Mechanical Tubing is a tough grade made by flat-rolling steel and welding it in place with an automated welding technique. These tubes do not require any filler material to be welded in place. We maintain various sizes of tubes in stock, which can be purchased at any of our locations. Our supply chain enables us to deliver things to your door in a timely manner. For additional information on these products or their pricing, please contact us or visit any of our locations.

Table of content

| Wall Thickness in Inch | 0.049 – 0.375 Inch |

| Manufacturing Type | DOM / Welded / Seamless / Fabricated / ERW / CDS / CDW / CEW |

| Surface Finish | polished 320 grit, Mill finish, Polished 180 grit |

| Sizes in Inch | ½ – 8 Inch Diameter |

| Standard | JIS, ASTM, EN, SUS, AISI, GB, DIN |

| Service | Decoiling, Bending, Punching, Welding, Cutting, Moulding |

| Technique | Cold rolled, Cold drawn, Hot rolled, Extrusion Tube |

A511M Grade Mt304 Mechanical Tube

ASTM A511 Seamless tube

ASTM A511 grade mt304

ASTM A511 Mt316 Stainless Steel Tube

Cold Finished ASTM A511 Tubing

MT310S large diameter ss tube

| GRADES | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| 304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Our vast inventory and efficient distribution make us the leading stockist and distributor for high-temperature A554 Ornamental Tubing.

| Material | Yield Strength | Temperure | Tensile Strength | Heat | Elongation |

| Ksi (MPa), Min. | Min.º F(º C) | Ksi (MPa), Min. | Treatment | ||

| 304 | 30(205) | 1900 (1040) | 75(515) | Solution | 35 |

| 304L | 25(170) | 1900 (1040) | 70(485) | Solution | 35 |

| 316 | 30(205) | 1900(1040) | 75(515) | Solution | 35 |

| 316L | 25(170) | 1900(1040) | 70(485) | Solution | 35 |

| UNS | EN-standard Steel no. k.h.s DIN |

SAE grade | EN-standard Steel name |

| S31600 | 1.4408 | 316 | G-X 6 CrNiMo 18-10 |

| S31703 | 1.4438 | 317L | X2CrNiMo18-15-4 |

| S40900 | 1.4512 | 409 | X6CrTi12 |

| S41000 | 410 | ||

| S30100 | 1.4310 | 301 | X10CrNi18-8 |

| 1.4318 | 301LN | X2CrNiN18-7 | |

| S3043 | 1.4307 | 304L | X2CrNi18-9 |

| S31653 | 1.4429 | 316LN | X2CrNiMoN17-13-3 |

| S31000 | 1.4841 | 310 | X22CrNi2520 |

| S30403 | 1.4306 | 304L | X2CrNi19-11 |

| S30453 | 1.4311 | 304LN | X2CrNiN18-10 |

| S30400 | 1.4301 | 304 | X5CrNi18-10 |

| S30409 | 1.4948 | 304H | X6CrNi18-11 |

| S30500 | 1.4303 | 305 | X5CrNi18-12 |

| 312 | X5CrNi30-9 | ||

| S31008 | 1.4845 | 310S | X 5 CrNi 2520 |

| S32100 | 1.4541 | 321 | X6CrNiTi18-10 |

| S32109 | 1.4878 | 321H | X12CrNiTi18-9 |

| S31603 | 1.4404 | 316L | X2CrNiMo17-12-2 |

| S31600 | 1.4401 | 316 | X5CrNiMo17-12-2 |

| S31653 | 1.4406 | 316LN | X2CrNiMoN17-12-2 |

| S31603 | 1.4432 | 316L | X2CrNiMo17-12-3 |

| S31603 | 1.4435 | 316L | X2CrNiMo18-14-3 |

| S31600 | 1.4436 | 316 | X3CrNiMo17-13-3 |

| S31635 | 1.4571 | 316Ti | X6CrNiMoTi17-12-2 |

| S32304 | 1.4362 | 2304 | X2CrNi23-4 |

| S31803/S32205 | 1.4462 | 2205 | X2CrNiMoN22-5-3 |

| S32760 | 1.4501 | J405 | X2CrNiMoCuWN25-7-4 |

| N08904 | 1.4539 | 904L | X1NiCrMoCu25-20-5 |

| N08926 | 1.4529 | X1NiCrMoCuN25-20-7 | |

| S31254 | 1.4547 | 254SMO | X1CrNiMoCuN20-18-7 |

Annealed ASTM A554 Round Tubing provides excellent formability and ease of fabrication.

| Gauge | 7 | 16 | 3/8 | 14 | 1/4 | 18 | 11 |

|---|---|---|---|---|---|---|---|

| Inches | 0.180 | 0.065 | 0.375 | 0.083 | 0.250 | 0.049 | 0.120 |

| 1-3/4 | 3.75 | 1.49 | 1.88 | 1.13 | 2.66 | ||

| 5/8 | 0.40 | 0.38 | |||||

| 3/4 | 65.00 | 0.81 | 0.50 | 1.13 | |||

| 1 | 2.17 | 0.83 | 1.03 | 0.63 | 1.45 | ||

| 3-1/2 | 8.06 | 10.89 | 5.67 | ||||

| 6 | 14.07 | 28.53 | 18.77 | 9.46 | |||

| 8 | 38.55 | 26.03 | |||||

| 1/2 | 0.39 | 0.30 | |||||

| 1-1/4 | 2.99 | 1.08 | 1.37 | 0.82 | 1.93 | ||

| 1-1/2 | 3.63 | 1.27 | 1.61 | 4.41 | 0.97 | 2.26 | |

| 2 | 4.46 | 1.69 | 2.14 | 6.01 | 1.30 | 3.06 | |

| 2-1/2 | 5.68 | 2.72 | 7.67 | 3.88 | |||

| 3 | 6.90 | 3.29 | 9.35 | 4.97 | |||

| 4 | 9.27 | 18.52 | 12.68 | 6.26 | |||

| 5 | 11.90 | 23.53 | 16.35 | 8.02 |

We offer A554 Tubing that is cut to length in any size

| Largest Specified Outer Diameter (in Inches/ mm) |

Outer Diameter | Wall Thickness | ||

| inches | mm | inches | mm | |

| ½ to 1 (12.7 to 25.4) | 00.005 | 00.13 | 00.020 to 0.065 | 00.51 to 1.65 |

| ½ to 1 (12.7 to 25.4) | 00.010 | 00.25 | 0.065 to 0.134 | 1.65 to 3.40 |

| 2 to 2½ | 00.012 | 00.30 | 00.032 to 0.065 | 00.81 to 1.65 |

| 1 to 1½ | 00.008 | 00.20 | 00.025 to 0.065 | 00.64 to 1.65 |

| 5 to 7½ | 00.030 | 00.76 | 0.250 | 6.35 |

| 3½ to 5 | 00.020 | 00.51 | 00.035 to 0.165 | 00.89 to 4.19 |

| 1 to 1½ | 00.010 | 00.25 | 0.065 to 0.134 | 1.65 to 3.40 |

| 1½ to 2 | 00.010 | 00.25 | 00.025 to 0.049 | 00.64 to 1.24 |

| Under ½ (12.7) | 00.004 | 00.10 | 00.020 to 0.049 | 00.51 to 1.24 |

| 1½ to 2 | 00.011 | 00.28 | 0.049 to 0.083 | 1.24 to 2.11 |

| 1½ to 2 | 00.012 | 00.30 | 0.083 to 0.149 | 2.11 to 3.78 |

| 7½ to 16 | 00.00125 in./ in. or mm/ mm of circumstances | all | all | |

| 2 to 2½ | 00.013 | 00.33 | 0.065 to 0.109 | 1.65 to 2.77 |

| 2 to 2½ | 00.014 | 00.36 | 0.109 to 0.165 | 2.77 to 4.19 |

| 2½ to 3½ | 00.014 | 00.36 | 00.032 to 0.165 | 00.81 to 4.19 |

| 2½ to 3½ | 00.020 | 00.51 | 0.165 | 4.19 |

| 3½ to 5 | 00.025 | 00.64 | 0.165 | 4.19 |

| 5 to 7½ | 00.025 | 00.64 | 00.049 to 0.250 | 1.24 to 6.35 |

Application of SA554 tubing

- Automotive applications

- Aerospace industry

- Water treatment

- Marine applications

- HVAC systems

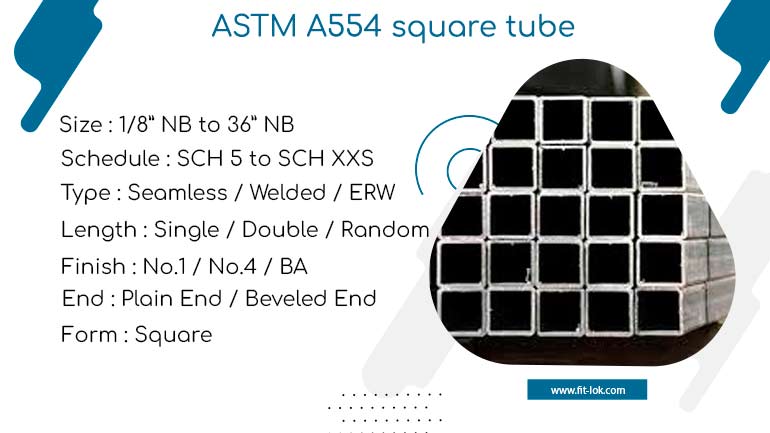

Packaging of ASTM A554 square tube

The packaging techniques for steel tubes differ based on their type and size. While we offer packaging methods for common pipe types, extra precautions may be necessary in certain instances to safeguard against damages caused by wiggling and bending during sealift handling and transportation.

Frequently asked questions

What are the key properties of ASTM A554 Rectangular Tube in terms of corrosion resistance, strength, and weldability?

ASTM A554 Rectangular Tube exhibit excellent corrosion resistance, high strength, and good weldability due to the use of stainless steel.

What are the common export requirements for A554 Tubing, such as packaging, documentation, and compliance with international standards?

Common export requirements for A554 Tubing include proper packaging to ensure product integrity, accurate documentation for customs clearance, and compliance with international standards and regulations.

How does the surface finish of ASTM A554 304 Tube affect their appearance and durability?

The surface finish of ASTM A554 304 Tube plays a significant role in both aesthetics and durability, with options such as brushed, mill, and polished finishes offering different levels of shine, smoothness, and resistance to corrosion.

Are A554 Grade Mt 316L Rectangular Tube available in different grades of stainless steel to meet specific application requirements?

Yes, A554 Grade Mt 316L Rectangular Tube are available in various grades of stainless steel, such as 304, 304L, 316, and 316L, allowing for selection based on the desired properties and environmental conditions of the application.

What are the quality control measures implemented during the manufacturing process of A554 Ornamental Tubing to ensure consistent and reliable product performance?

The manufacturing of A554 Ornamental Tubing involves rigorous quality control measures, including material inspection, dimensional checks, welding integrity tests, and surface finish evaluation, ensuring consistent and reliable product performance.