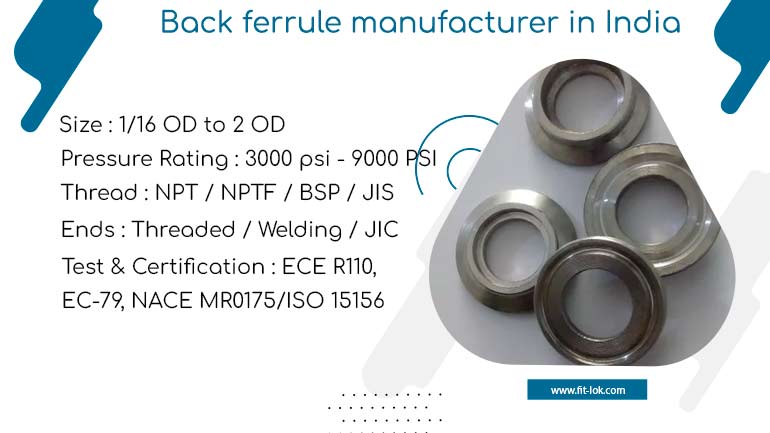

Stainless steel back ferrule manufacturer in India

A back ferrule is a small but important element of tube fittings that secures the tube within the fitting body and creates a reliable seal. Back ferrules, like front ferrules, are often made of tough materials such as stainless steel, brass, or other high-performance alloys that can endure high pressures and temperatures.

Explore the comprehensive dimensions and sizes available for Brass back ferrule

The use of front and back ferrules improves sealing integrity, resulting in leak-free connections in fluid systems. Back ferrules manufactured of strong materials can endure high pressures and temperatures, making them trustworthy in high-pressure applications. Back ferrules’ strong grip avoids fluid leaks, helping to the overall efficiency and safety of the fluid system.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

back ferrule compression fittings

stainless steel back ferrule

Stainless Steel 304 back Ferrule Tube Fitting

316 Stainless Steel back ferrule

Brass back ferrule

Incoloy Alloy 825 back ferrule

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

We offer Incoloy Alloy 825 back ferrule at the cheapest rates

- HVAC systems

- Water treatment

- Marine applications

- Aerospace industry

- Automotive applications

We are a reputable manufacturer specializing in medium-pressure back ferrule tube fittings

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Inconel 600 back ferrule are capable of withstanding pressures up to 22,500 psi

Packaging of back ferrule

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

How should a back ferrule be installed?

To install a back ferrule, slide it onto the tube after the front ferrule has been positioned. After inserting the tubing with the back ferrule into the fitting, tighten the fitting nut to compress both ferrules and produce a firm connection.

What are the benefits of utilising back ferrules in tube fittings?

Back ferrules offer various benefits, including increased tubing connection support and stability, resistance to vibration and pressure fluctuations, prevention of tubing disconnection under pressure, and improved sealing performance when used in conjunction with front ferrules.