We are Aluminum camlock fittings Manufacturer in India

Camlock couplings are a form of quick connect coupling that is made up of two components: a male adapter and a female coupler. The grooved end of the male adapter is put into the female coupler, which features a cam arm that locks into place to provide a secure connection. Camlock couplings are designed to be simple to connect and disengage, making them excellent for applications requiring frequent hose or equipment changes.

DIN2828 camlock couplings are camlock couplings that meet the DIN 2828 standard. This standard specifies the dimensions and specifications for industrial camlock couplings. Brass Camlock Fittings are common in applications requiring corrosion protection, such as the marine and chemical industries.

Check Dimension and Size Chart of Brass camlock fittings

Male Camlock Fittings come in a variety of sizes and materials, such as stainless steel, aluminium, and brass. Banjo Camlock Fittings are typically utilised when a hose or pipe must be attached at an angle. Female camlock couplings have a cam arm that locks into place when the male adapter is inserted.

Table of content

- Specification of Camlock couplings

- Types of camlock couplings

- Dimensions of Camlock fittings

- Pressure rating of male camlock coupling

- Features of aluminum camlock fittings

- Size range of Camlock couplings

- Benefits of Camlock Fittings

- Various Configurations Of Camlock Fittings

- Application of female camlock fittings

- Maintenance and Care Of high pressure camlock fittings

- How do camlock fittings work

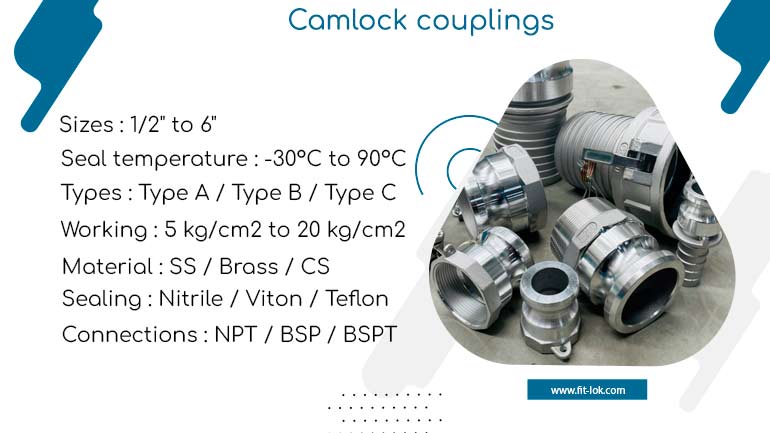

| Sizes | 1/2″, 3/4″,1″,1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″, 5″, 6″ |

| Working | 5 kg/cm2 to 20 kg/cm2 (working varies according |

| Pressure | to the size of coupling ) |

| Material | Aluminium,Bronze, Carbon Steel,S.S.304, S.S.316 PP / Cement,Fertilizers,Fire Fighting Equipment,Ink / Dye / |

| Paint Industries ,Petrochemical / Refineries / Process Industries, Mining, Oil Drilling Companies | |

| Application | (offshore / onshore ), Railways,Steel Plants, Military, Applications, Pneumatic Conveyors,Oil Blending Plants, |

| Automobile manufacturers, Chemical Industries and Furnaces. |

Camlock couplings

Aluminum camlock fittings

Brass camlock fittings

| Cam and Groove Gaskets | ||||||||||||

| Size (inch) | ½” | ¾” | 1” | 1 ¼” | 1 ½” | 2” | 2 ½” | 3” | 4” | 5” | 6” | |

| Material | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| Buna N | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| EPDM | √ | √ | √ | √ | √ | √ | √ | |||||

| Viton | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| WORKING PRESSURES, PSI | |||||||

| Material | ½” | ¾”- 2” | 2½” | 3” | 4” | 5” | 6” |

| Brass | 150 | 250 | 150 | 125 | 100 | 75 | 150 |

| Aluminum | 150 | 250 | 150 | 125 | 100 | 75 | 150 |

| Stainless Steel 316 | 150 | 250 | 225 | 200 | 100 | 100 | 200 |

| Polypropylene | 75 | 100 | – | 50 | – | – | – |

- Compact Design

- Pressure Rating

- Locking Mechanism

- Versatility

- Ease of Maintenance

| Size | 1/2″ | 3/4″ | 1″ | 11/4″ | 11/2″ | 2″ | 21/2″ | 3″ | 4″ | 5″ | 6″ |

| A | 14 | 14 | 24 | 28 | 35 | 51 | 58 | 72 | 98 | 122 | 145 |

| B | 52 | 52 | 64 | 72 | 73 | 80 | 90 | 94 | 101 | 102 | 118 |

| E | 32 | 32 | 40 | 48 | 49 | 54 | 59 | 60 | 62 | 32 | 72 |

| G | 53 | 53 | 60 | 78 | 85 | 96 | 110 | 127 | 156 | 185 | 220 |

- Easy to use

- Leak-resistant

- Versatile

- Durability and Longevity

- Cost-effective

- Can operate in dirty environments

- Type A

- Type B

- Type C

- Type D

- Type E

- Type F

- Type DC

- Type DP

- Oil and Gas Industry

- Manufacturing Industry

- Construction Industry

- Marine Industry

- Mining Industry

- Pharmaceutical Industry

- HVAC and Plumbing

If you want to maintain your camlock couplers in the installations that are best fitting, you need to understand how to do camlock fittings measurement. It is mandatory to have the appropriate size of the male/female pieces.

- Ensure that the camlock fittings are clean and dry before the storage is done.

- If you are going to store the Camlock coupler for a long time, paint the protective coating all over again.

- To facilitate easy storage, the male and female parts of camlock fittings should be disconnected.

- Do not expose them to direct sunlight, rain or cold as they will be affected. Avoid displaying the products outdoors as much as is possible.

- Avoid placing on top of each other the camlock couplers.

Camlock Fittings function essentially through a lever arm coupling mechanism that enables easy connection and disconnection. Before connecting a camlock fitting, the fitting’s arms of the female coupling should be in the open position. After that, screw the plug end of the male adapter to the female coupler end. To lock the two halves, clients must close both handles simultaneously to compress the gasket on the inner surface.