ASTM A105 Poppet Check Valve Manufacturer in India

Carbon steel swing check valve are available in different threads such as NPT, BSP and BSPT

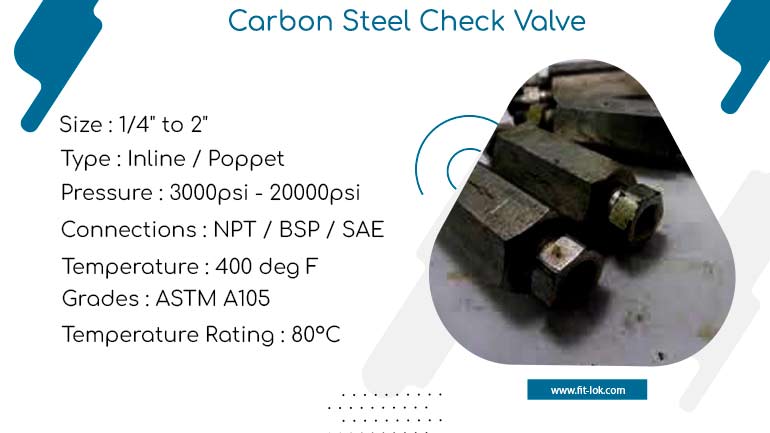

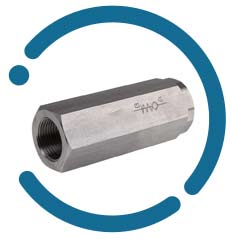

We are manufacturer, exporter and supplier of Carbon steel check valve in size range of 1/2″ to 2″. These valves contain upto 2% carbon content and can withstand temperature range of − 29°C to 400°C. ASTM A105 Poppet Check Valve requires a minimum pressure differential between the inlet and the outlet to open, which allows media to flow through it. This minimum pressure at which valves opens is known as cracking pressure.

Correct installation orientation is important while installing Carbon steel swing check valve because it is a one way valve. These valves shuts off the flow in case of backflow. When we compare to other hard materials ASME SA105 Spring Check Valve has more strength and hardness due to its carbon content. To prevent failure of these valves routine checkup, proper installation and maintenance is must.

Fit-lok is leading Carbon steel check valve manufacturer in India, We Stock and supply these valves to more than 30 countries worldwide. We make sure that quality of products are always maintained. Our testing facility eliminate any damaged Carbon Steel Poppet Check Valve from manufacturing batch to ensure every valve can work in high temperature and pressure condition for longer duration. Carbon Steel Piston Check Valve comes in socket weld and threaded connections.

Table of content

- Carbon steel check valve specification

- CS instrumentation check valve types

- ASTM A105 Check Valve price list

- Carbon Steel Spring Check Valve Chemical compostion

- Carbon Steel Piston Check Valve Physical properties

- Size chart of A105 Spring Check Valve

- ASME SA105 hydraulic check valve dimensions

- Material of construction of Carbon steel check valve

- How Carbon Steel Instrumentation Check Valves Work

- Advantages of Carbon steel A105 Instrument Control Valve

- Factor to consider while buying CS check valve

- Applications of Mild Steel Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Carbon Steel Hydraulic Check Valve

ASTM A105 Inline Check Valve

Low Carbon Steel Nrv Valve

SA 105 Instrument Air Check Valve

High Carbon Steel Non Return Valve

A105 Spring Check Valve

ASME SA105 Instrumentation Check Valve

Carbon steel A105 Poppet Check Valve

CS Instrument Control Valve

Purchase Carbon Steel Poppet Check Valve at factory price in 3000 PSI to 15000 PSI pressure rating range

Price of CS instrumentation check valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Carbon Steel Spring Check Valve you can contact us on sales@fit-lok.com

| Carbon | Copper | Sulphur | Phosphorus | Silicon |

| 0.0026 | 0.020 | 0.005 | 0.004 | 0.04 |

| MECHANICAL PROPERTIES | METRIC |

| Tensile Strength, Ultimate | 540 MPa |

| Tensile Strength, Yield | 415 MPa |

| Modulus of Elasticity | 200 GPa |

Refer sizes and dimensions of ASME SA105 Spring Check Valve

| END CONNECTIONS | DIMENSIONS in MM | PRESSURE RATING 100°F (37°C) PSIG | Cv | ||

| INLET / OUT LET | L | A/F | |||

| MALE x MALE NPT | 1/8″ | 60 | 19 | 6000 | 0.82 |

| 1/4″ | 68 | 22 | 6000 | 1.40 | |

| 3/8″ | 70 | 25 | 6000 | 1.52 | |

| 1/2″ | 82 | 27 | 6000 | 1.70 | |

| 3/4″ | 85 | 36 | 6000 | 4.85 | |

| 1″ | 92 | 45 | 6000 | 8.30 | |

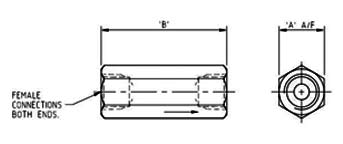

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| Name | Part No. |

|---|---|

| Body | A105 |

| Nut | A194 Gr 8 |

| Seat | A276 410 |

| Disc | A276 420+STL |

| Bonnet | ASTM A105 |

| Bolt | ASTM A193 B8 |

| Arm | A182 F304 |

| Gasket | SS304+Graphite |

A carbon steel instrumentation check valve operates by allowing fluid to flow only in one direction, It automatically closes when the flow reverses due to a movable disc or ball mechanism within the valve body, effectively preventing backflow

- Strength and Durability

- Cost-Effective

- Good Weldability

- High-Temperature Resistance

- Good Impact Resistance

- Ease of Maintenance

- Available in Multiple Configurations

- Pressure Rating

- Temperature Range

- Material Strength

- Fluid Type

- Size and Flow Capacity

- Type of Check Valve

- Design and Construction

- Backflow Prevention

Carbon Steel Piston Check Valve widely used in industrial process and utility applications

- Pharmaceutical Industries

- Food and Beverage Industry

- Automotive Systems

- HVAC Systems

- Oil and Gas Industry

- Offshore Applications

- Petroleum industry