Refer Swing Check Valve Sizes and Dimensions

Leading supplier and exporter of pilot operated check valve in 10000 PSI rating

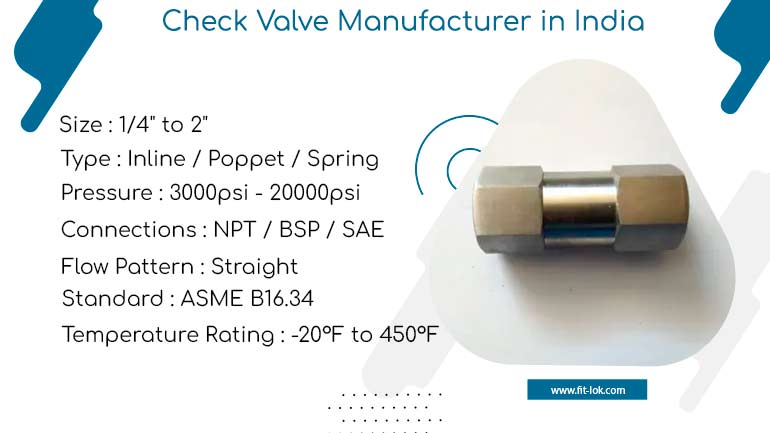

Check valve is basically a type of direction control valve which primarily used to control the direction of the fluid in hydraulic system. It is a unidirectional valve it only allows liquid to flow in one direction. Fit-lok is trusted Check valve manufacturer in India in size range of 1/2″ to 2″. We don’t compromise in terms of quality of material while manufacturing Swing Check Valve, Raw material is sourced from trusted and certified suppliers.

Pilot operated check valve inexpensive and easy solution for the potential issue which media backflow can cause. Backflow of media can cause contamination of upstream media, it can cause damage to equipment, it could increase a maintenance costs and system inefficiency.

Flow of media in Hydraulic check valve remain steady as long as the pressure is sufficient to keep the disc open, once the pressure drops, the disc automatically returns to its seat, which shut off the flow. The pressure required to open the high pressure check valve is known as cracking pressure which typically ranges between 3 psi to 350 psi depending on the size of valve. These valves create a tight seals to prevent any leaks.

Female X Female Check Valve has threads on both the ends. These valve can withstand pressure upto 15000 PSI. We are one of the leading double check valve supplier in India and can supply it to countries like Nigeria, UAE and South Africa. We keep ready stock of female non return valve in pressure range of 3000 PSI to 20000 PSI. These valves are tested using various destructive and non destructive methods to ensure the quality of products.

Table of content

- Check valve Specification

- Different types of Non return valve

- Check valve price list

- Check valve cracking pressure

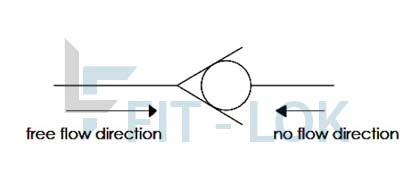

- Hydraulic check valve symbols

- Pressure and Temperature rating of Female X Female Check Valve

- Dimensions of Pneumatic check valve

- Working Temperature of Check valves

- Flow type and recommendation of check valve

- Manufacturing standards of female threaded check valve

- Inline check valve functions

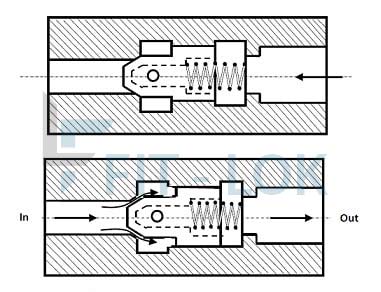

- Diagram of Poppet check valve

- Applications of compressor check valve

- How to select right Air compressor check valve

- Can non return valve stop water hammer?

- Advantages and Disadvantages of Compressor check valve

Hydraulic check valve can withstand temperatures from -25 °C to 200 °C

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Hydraulic Check Valve

Inline Check Valve

Nrv Valve

Instrument Air Check Valve

Non Return Valve

Spring Check Valve

Instrumentation Check Valve

Poppet Check Valve

Instrument Control Valve

Get updated price list of high pressure check valve

Price of Hydraulic check valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Instrument Control Check Valve you can contact us on sales@fit-lok.com

| Types | Cracking Pressure |

| Poppet Check Valves | 1/3 to 25 psig |

| One-Piece Check Valves | 1/3 to 25 psig |

| Lift Check Valves | 3 to 600 psig |

Buy Female X Female Check Valve at factory price from stockist in Mumbai

| Material | 316 SS | Brass |

| Temperature, °F (°C) | Working Pressure, psig (bar) | |

| –10 (–23) to 100 (37) | 2000 (137) | 1500 (103) |

| 200 (93) | 1715 (118) | 1300 (89.5) |

| 250 (121) | 1630 (112) | 1200 (82.6) |

| 300 (148) | 1545 (106) | — |

| 375 (190) | 1450 (99.9) | — |

| End Connections | Dimensions, in. (mm) | |||

| Inlet/Outlet | Size | A | B | C |

| Fractional tube fittings | 1/8 in. | 2.14 (54.3) | 5/8 | 7/16 |

| 1/4 in. | 2.35 (59.7) | 9/16 | ||

| 3/8 in. | 3.17 (80.5) | 7/8 | 11/16 | |

| 1/2 in. | 3.42 (86.9) | 7/8 | ||

| 3/4 in. | 4.32 (110) | 1 1/4 | 1 1/8 | |

| 1 in. | 4.74 (120) | 1 3/8 | 1 1/2 | |

| Metric tube fittings | 6 mm | 2.36 (59.9) | 5/8 | (14) |

| 10 mm | 3.32 (84.3) | 7/8 | (19) | |

| 12 mm | 3.42 (86.9) | (22) | ||

| Female NPT | 1/8 in. | 1.89 (48.0) | 5/8 | — |

| 1/4 in. | 2.15 (54.6) | 3/4 | ||

| 3/8 in. | 2.98 (75.7) | 7/8 | ||

| 1/2 in. | 3.58 (90.9) | 1 1/16 | ||

| 3/4 in. | 4.08 (104) | 1 1/4 | ||

| 1 in. | 4.84 (123) | 1 5/8 | ||

| Male NPT | 1/8 in. | 1.71 (43.4) | 5/8 | |

| 1/4 in. | 2.09 (53.1) | |||

| 3/8 in. | 2.78 (70.6) | 7/8 | ||

| 1/2 in. | 3.16 (80.3) | |||

| 3/4 in. | 4.08 (104) | 1 1/4 | ||

| 1 in. | 4.52 (115) | 1 5/8 | ||

| Male NPT/ tube fitting | 1/4 in. | 2.22 (56.4) | 5/8 | 9/16 |

| Male VCR fittings | 1/4 in. | 2.21 (56.1) | 5/8 | — |

| 1/2 in. | 3.56 (90.4) | 15/16 | ||

| 3/4 in. | 4.64 (118) | 1 5/8 | ||

| 1 in. | 4.76 (121) | |||

| Working Temperature | -23°C to 190°C |

|---|

| Type Flow | Recommended Check Valve | Media Type | Velocity Range FPS(m/s) |

|---|---|---|---|

| Uniform With Insignificant Reversal | Swing Check w/ Lever and ctrl wt. | Water Or Oil | 1 to 6 (0.3 to 2) |

| Simple Swing | Steam, Water, Gas | 7 to 100 (2 to 30) | |

| Pulsating | In-line Guided Disc w/Cushion Chamber | Air Or Gas | 5 to 10 Max (a.5 to 3) |

| Uniform | In-line Guided Disc | Water Or Oil | 5 to 10 Max (a.5 to 3) |

| Uniform With Severe Reversal | Swing w/ Dashpot | Water Or Oil | 7 to 10 (2 to 3) |

| Uniform With Normal Reversal | Swing w/ Spring Assist To Close | Water Or Oil | 7 to 10 (2 to 3) |

| Uniform Or Pulsating (Severe Revesal) | Tee- Pattern Lift w/ Dashpot | Steam, Water, Or Gas | 10 to 160 (3 to 50) |

| Uniform Or Pulsating | Tee- Or Inclined- Pattern Lift | Steam, Water, Or Gas | 8 to 160 (2.5 to 50) |

| Uniform Or Pulsating | Wye-Pattern Lift | Steam, Water, Or Gas Or Oil | 20 to 250 (6 to 75) |

| Uniform | Tilting Disc | Steam, Water, Or Gas | 12 to 250 (4 to 75) |

- ASME B16.10

- BS 1868

- ASME B16.5

- API 6D / API 598

- MSS SP-55

- ASME B16.34

- MSS SP-25

- Preventing Backflow

- Maintaining System Pressure

- Protecting Pumps and Equipment

- Maintaining Fluid Quality

- Preventing Water Hammer

- Flow Direction Control

- Ensuring Process Efficiency

- Preventing Damage from Flow Loss

- Refineries

- Food and Beverage Industry

- Water Treatment Plants

- Marine Applications

- Chemical Processing

- Oil & Gas Industry

- Power Generation

- Pulp and Paper Industry

- Material Selection

- Performance Requirements

- Type and Size

- Maintenance

- Cracking pressure

- Flow direction

- Fluid density

Water hammer can be avoided by employing check valves that close rapidly, thus avoiding pressure surges and shock waves. Silent check valves are one of the effective solutions to this problem.

Advantages

- Prevent backflow

- Self-actuated

- Prevent water hammer

- Reduce sudden valve failure

- Lower maintenance costs

- Few moving parts

- Smaller footprint

- Do not require power to operate

Disadvantages

- Do not operate in pulsating systems

- Noise from slamming discs

- Reverse flow problems

- Operate in a completely enclosed system

- Internal parts cannot be checked