Choose us as your Female brass tee fitting manufacturer in India

A female run tee, also known as a female branch tee or female tee, is a three-hole pipe fitting. It is made up of a female-threaded connection at one end and two female-threaded connections at the other, making a “T” shape. The female run tee enables the insertion of a branch line perpendicular to the main pipeline, allowing fluids to be distributed to multiple places.

Leading stockist in Mumbai for high-quality female run tee fitting products, ensuring quick availability for your project needs.

A female run tee’s principal function is to connect branches in a fluid system. It allows fluids to travel to numerous destinations by connecting the main pipeline to one end and branching off with two auxiliary pipelines. This branching feature is extremely useful in a variety of applications, including irrigation systems and pneumatic circuits.

Table of content

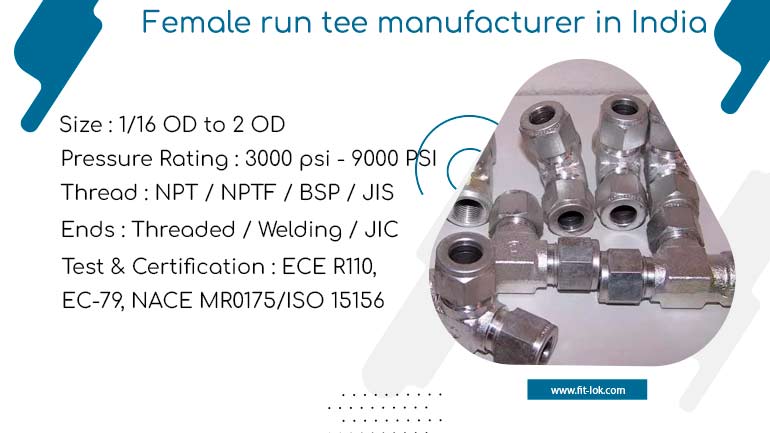

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

female run tee fitting

stainless steel female run tee

female brass tee fitting

female branch tee fitting

female pipe fittings tee

female compression tee

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

Stay updated with the latest stainless steel female run tee and female branch tee fitting price list to make informed purchasing decisions for your business

- Brewing equipment

- Marine applications

- Aerospace industry

- Dairy equipment

- Automotive manufacturing

As a trusted supplier in Asia, we offer a wide range of female pipe fittings tee products with various dimensions to suit your specific requirements

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Reliable distributor of female compression tee and Female Branch Tee products, specializing in serving the offshore platform industry with top-notch solutions

Packaging of Female Branch Tee

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is the purpose of a Female run tee in a fluid or gas system, and how does it facilitate the branching of flow?

The purpose of a Female run tee in a fluid or gas system is to facilitate the branching of flow by providing a female threaded end for connection to another component or branch line.

What are the common sizes and thread types available for Female run tees, and how do they ensure compatibility with various system components?

Female run tees are available in various common sizes and thread types, such as NPT (National Pipe Thread) or metric threads, ensuring compatibility with different system components and facilitating easy installation.

What considerations should be taken into account when selecting a Female run tee

When selecting a Female run tee, key considerations include ensuring material compatibility with the fluid or gas being conveyed, checking the pressure rating to match the system requirements, and following installation requirements such as proper thread sealing and torque specifications for a secure and leak-free connection.