One of the best Stainless steel ferrule nut manufacturer in India

A ferrule nut is a type of nut that is used to secure and tighten tube fitting assemblies. It is often used in conjunction with a front and rear ferrule to form a strong and leak-proof connection between the tube and the fitting body. The ferrule nut is essential for compressing the ferrules against the tube, ensuring a tight seal and preventing leakage.

Stockist of ferrule nut fitting in Mumbai

A ferrule nut’s principal role is to generate the force required to compress the front and back ferrules against the tube during assembly. Tightening the ferrule nut puts pressure on the ferrules, causing them to hold the tube tightly and produce a secure seal. This device ensures that there are no leaks in the fluid system, which contributes to its overall efficiency and safety.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

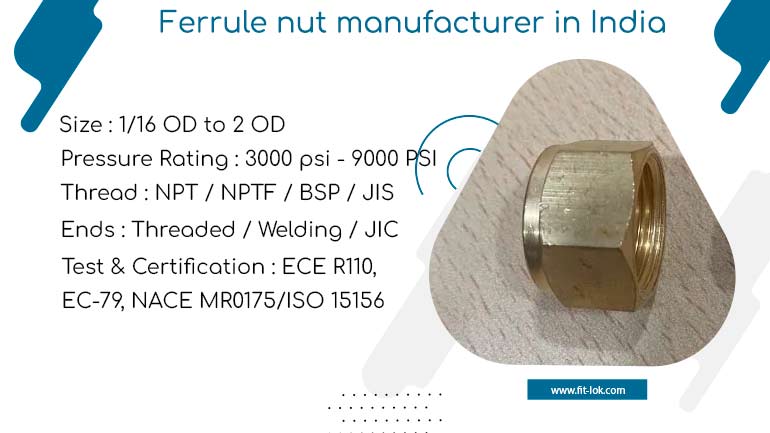

ferrule nut fitting

brass ferrule nut

stainless steel ferrule nut

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

check brass ferrule nut price list

- Marine applications

- Brewing equipment

- Automotive manufacturing

- Aerospace industry

- Dairy equipment

Supplier of compression nut and ferrule in Asia, check carbon steel ferrule nut fitting dimensions

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Distributor of hastelloy ferrule nut and Alloy steel ferrule nut for offshore platform

Packaging of compression nut and ferrule

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is a Ferrule nut, and how is it used in tube fittings to create a secure and leak-tight connection?

A Ferrule nut is a component used in tube fittings to create a secure and leak-tight connection by compressing the ferrule against the tubing and forming a seal.

What are the common sizes and materials available for Ferrule nuts, and how do they ensure compatibility with various tubing materials and system requirements?

Ferrule nuts are available in various common sizes and materials, such as stainless steel or brass, ensuring compatibility with different tubing materials (e.g., stainless steel, copper) and meeting specific system requirements.

What considerations should be taken into account when selecting a Ferrule nut

When selecting a Ferrule nut, considerations include the fitting design (single or double ferrule), pressure rating to match system requirements, and following proper installation procedures (e.g., appropriate torque, alignment) to ensure reliable performance in fluid or gas systems.