Buy flushing ring for pressure gauge and diaphragm seals at factory price

A flushing ring is a pressure instrument accessory that prevents process material from accumulating in the pressure instrument. It’s usually put between the process connection and the pressure gauge. Depending on the use, flushing rings can be manufactured of various materials such as stainless steel, brass, or Hastelloy.

Top notch stockist and manufacturer of flush flange

A flush flange is a flushing ring that is intended for use with flanged pressure instruments. It’s positioned between the process and instrument flanges to create a flush surface for the pressure gauge. Flush flanges are frequently employed in applications where the process medium contains particles or viscous components that can clog the pressure instrument.

The usage of flushing rings has various advantages, including:

- Pressure measurement accuracy has been improved.

- Pressure instruments are less likely to clog.

- Pressure instrument lifespan is extended

- Lower maintenance expenses

- Process control has been improved.

Table of content

| BODY SIZE | 1/2″ NB TO 8″ NB |

| CLASS | 150#, 300#, 600#, 900#, 1500#, 2500# |

| SEALING FACE | AMSE B16.5 RAISED FACE (RF), RING TYPE JOINT (RTJ) |

| FLUSHING PORT SIZE | 1/2″ NPT (F) & 1/4″ NPT (F), BUTT WELD, SOCKETWELD |

| THREADS | NPT, BSPP, BSPT |

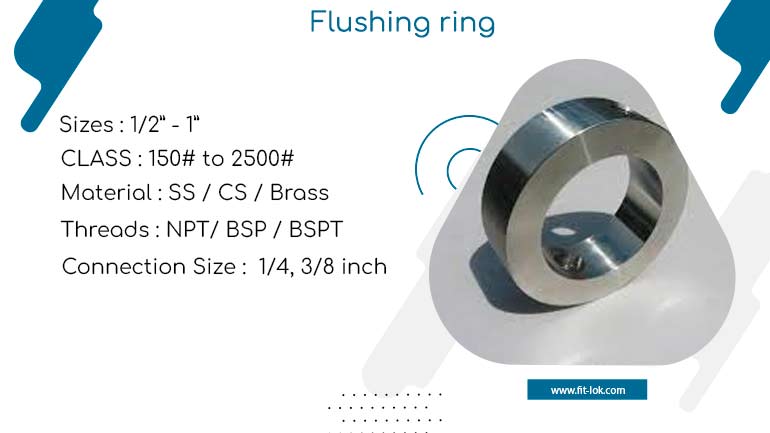

Flushing ring

Flushing ring for pressure gauge

Flush flange

| NPS | ID | OD by Pressure Class | ||||

| 150 | 300 | 600 | 900 | 1500 | ||

| 1 | 28.6 | 63.5 | 69.9 | 69.9 | 76.2 | 76.2 |

| 1½ | 41.3 | 82.6 | 92.1 | 92.1 | 95.3 | 95.3 |

| 2 | 54 | 101.6 | 108 | 108 | 139.7 | 139.7 |

| 2½ | 63.5 | 120.7 | 127 | 127 | 161.9 | 161.9 |

| 3 | 79.4 | 133.4 | 146.1 | 146.1 | 165.1 | 171.5 |

| 4 | 104.8 | 171.5 | 177.8 | 190.5 | 203.2 | 206.4 |

| 6 | 155.6 | 219.1 | 247.7 | 263.5 | 285.8 | 279.4 |

| 8 | 203.2 | 276.2 | 304.8 | 317.5 | 355.6 | 349.3 |

| 10 | 257.2 | 336.6 | 358.8 | 396.9 | 431.8 | 431.8 |

| 12 | 304.8 | 406.4 | 419.1 | 450.9 | 492.1 | 514.4 |