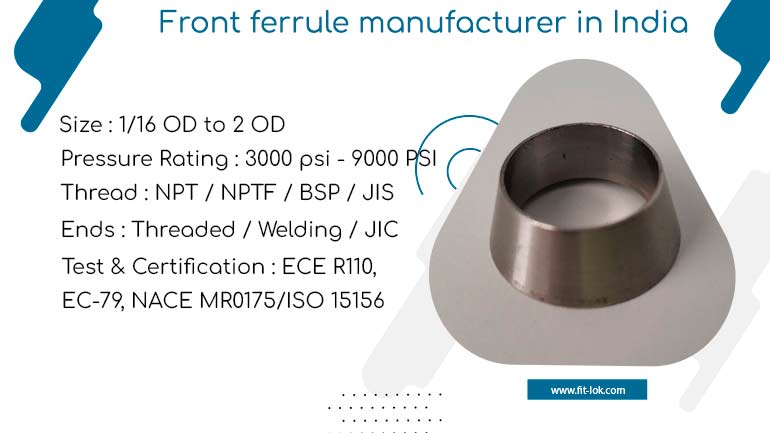

One of the best Stainless steel m1a front ferrule manufacturer in India

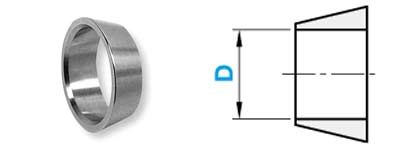

A front ferrule is a small but important component used in tube fittings to form a tight and leak-proof connection between two tubes or between a tube and a fitting. Front ferrules are typically made of strong materials such as stainless steel, brass, or other high-performance alloys. They are designed to endure high pressures and temperatures while preserving structural integrity.

Trust us as your dependable exporter of front brake hose ferrule

The principal function of the front ferrule is to hold and seal the tube when it is crushed against the fitting body. The front ferrule of a tube fitting is positioned at the leading edge of the fitting’s nut when it is assembled. The front ferrule compresses against the tube as the nut is tightened, forming a firm seal between the tube and the fitting. This mechanism avoids any potential leakage, maintaining the efficiency and safety of the fluid system.

Why choose fit-lok to purchase front ferrules?

We are one the leading and known brand who is manufacturer of front ferrule in India. These are widely used in gas systems, instrumentation, and process control. Below are the some prominent reasons makes us suitable supplier for your front ferrules needs.

- High-Quality Materials

- Reliable Performance

- Versatility

- Precision Engineering

- Cost-Effective

- Ease of Installation

- Leak-Free Connections

- Strong Reputation

- Compliance with Industry Standards

- Customer Support & Warranty

Table of content

| Front Ferrules sizes in Inch | M1a front ferrule sizes in mm | Front ferrule manufacturing techniques |

|---|---|---|

|

|

|

| Stainless steel Front ferrule Tensile Strength | SS Front ferrule temperature range | Equivalent To |

|

|

|

| Ends | Pressure Rating | Nickel Front ferrule connection type |

|

|

|

| Front ferrule thread specification | Medium | Standard tagging & marking on m1a front ferrule |

|

|

|

| Quality compliance & inspection | Front ferrules Seal Type | Features |

|

Are you looking for front ferrule suppliers who have supplied globally including Saudi Arabia, USA, Oman, South Africa, Egypt & Qatar |

|

front ferrule fitting

m1a front ferrule

front brake hose ferrule

1/2 front ferrule

stainless steel front ferrule

carbon steel front ferrule

| Stainless Steel Front ferrule |

|

| Duplex / Super Duplex m1a front ferrule |

|

| Titanium Front ferrule |

|

| Hastelloy m1a front ferrule |

|

| Nickel Alloys Front ferrule |

|

| Inconel m1a front ferrule |

|

| Metric tubing | Imperial tubing |

| Tube Outside Diameter mm | Tube Outside Diameter inch |

| 3 | 1/16 |

| 4 | 1/8 |

| 6 | 3/16 |

| 8 | 1/4 |

| 10 | 5/16 |

| 12 | 3/8 |

| 16 | 1/2 |

| 18 | 5/8 |

| 20 | 3/4 |

| 25 | 7/8 |

Leading 1/2 front ferrule supplier in India, we prioritize offering the lowest rates without compromising on the quality of our products

- Aerospace industry

- Dairy equipment

- Marine applications

- Automotive manufacturing

- Brewing equipment

Get detailed information on the dimensions and sizes of our carbon steel front ferrule

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Choose us as your reliable exporter of 316 Stainless Steel Front Ferrule

Packaging of front ferrule fitting

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is the purpose of a front ferrule?

A front ferrule is used to provide a seal and grip on the tubing when it is inserted into a fitting, which ensures a secure and leak-free connection.

How does a front ferrule work?

The front ferrule is compressed against the fitting body when the tubing is inserted into a fitting. This compression causes the ferrule to deform and bite into the tubing, creating a solid seal and preventing leakage.

What are the common materials used for front ferrules?

Front ferrules are typically made from stainless steel, brass, or plastic (such as PTFE or nylon). The choice of material depends on the application requirements, compatibility with the fluid being transported, and the desired level of strength and durability.