Buy Gauge Isolator Valve from manufacturer at factory price

We are leading pressure gauge valve supplier in various pressure ratings

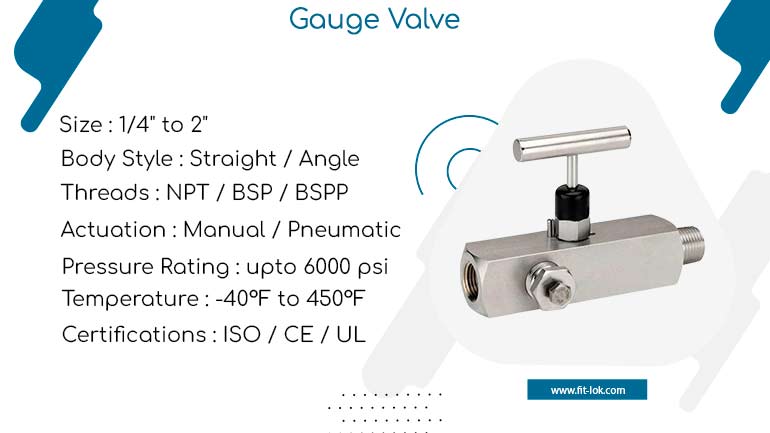

Gauge valves are designed for safe installations of Transmitter and Pressure gauges. It protects pressure gauge from damage caused due to pressure surge, hydraulic shock and vibrations. These valves comes in various designs which ranges from single isolation with bleed port to block and bleed valves with multiple connections. Pressure gauge valve are come in standard range of 413 bar but we can provide it upto 689 bar (10,000psi) in different materials. We are one of the leading Gauge valves manufacturer in India.

Gauge Isolator Valve are manufactured according to DIN 16270 standard. The body’s production occurs through a union bonnet pattern. A swivel female outlet at G 1/4 allows users to position Pressure gauges properly. The Bleed screw functions as the Vent for the device. Pressure Gauge Isolation Valve comes in different threads like NPT, BSP, BSPT and BSPP. Fit-Lok is reliable supplier of Gauge Snubber Valve in Mumbai.

If you are looking to purchase Gauge Root Valves in Qatar, Malaysia or Indonesia feel free to contact us as we have ready stock of these valves and can supply it within 7 to 10 days at your location. We conduct various destructive and non destructive tastings are performed on Gauge Snubber Valve to prevent any kind of failure in working conditions. To ensure complete satisfaction of buyers we have implemented quality control norms at our factory. While packaging we make sure that product should not get damaged during transit. Our team of professionals make sure that you get seamless service before and after purchasing a gauge valve.

Table of content

- Gauge valve Specification

- Types of pressure gauge valve

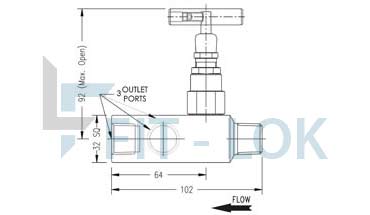

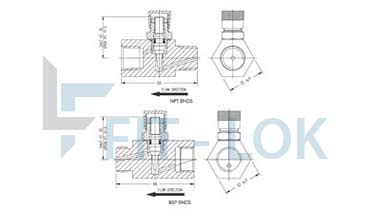

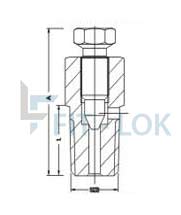

- Diagram of Gauge Root Valves

- Design features of Gauge Snubber Valve

- Parts and material of construction of Gauge Isolator Valve

- Pressure Gauge Isolation Valve pressure temperature rating

- Multi port Gauge Valve sizes

- Size chart of Adjustable Pressure Gauge Snubber Valve

- Dimensions of Drain Valve

- Quality and testing of Pressure Reducing Valve With Gauge

- Application of Gauge Root Valves

| Size Range |

|

| Connection |

|

| Body Shape | Hexagon |

| Threads |

|

| Pattern Flow | Straight |

| Equivalent Brands |

|

| Orifice Size | 2 MM – 40 MM |

| Pressure Rating |

|

| Type |

|

| Body Type | Forged, Bar Stock |

| Media |

|

| Packing Details |

|

Check sizes and dimensions of Pressure Gauge Isolation Valve

Gauge Root Valves

High pressure valve

Pressure gauge valve

Gauge Isolator Valve

Gauge Snubber Valve

Pressure Gauge Isolation Valve

Gauge Snubber Valve used to regulate the flow of fluids

- Compact Design

- Self aligning metal seats

- Non-rotating spindle tip

- Bonnet Locking pins

- 100% pressure tested

Gauge Root Valves are available in various threads like NPT, BSPP and BSPT

| Component | Material Grade/ ASTM Specification |

|---|---|

| Handle pin, set screw | S17400 SS/A564 |

| Packing bolt | 416 SS/A582 |

| Packing supports (2) | Reinforced PTFE |

| Packing | PTFE/D1710, D1708, D792 |

| Seat (plug‑tip design) | Acetal/D6778, PEEK, or PFA/D3307 |

| Handle, gland, lock nut, washer, lock plate, cap screw (3/16 in. hex key) |

316 SS |

| Stem (ball‑ and plug‑ tip design), ball (ball‑tip design) |

316 SS/A276 |

| Body, bonnet | 316 SS/A479 |

| Lubricants | Fluorinated‑, PTFE, and tungsten disulfide‑based, nickel antiseize in a hydrocarbon carrier, and hydrocarbon‑ based (all packing materials); molybdenum disulfide‑based (PEEK packing material) |

| Stem Design | Ball Tip | Plug Tip | |||

| Seat Material | 316 SS | PFA | Acetal① | PEEK | |

| Packing Material | PTFE | Grafoil® | PTFE | PEEK | |

| Temperature, °F (°C) | Working Pressure, psig (bar) | ||||

| –65 (–53) to 100 (37) 200 (93) 250 (121) 300 (148) 350 (176) |

6000 (413) 5160 (355) 4910 (338) 4660 (321) 4470 (307) |

6000 (413) 5160 (355) 4910 (338) 4660 (321) 4470 (307) |

750 (51.6) 625 (43.0) 450 (31.0) 300 (20.6) 200 (13.7) |

6000 (413) 2650 (182) 1000 (68.9) — — |

6000 (413) 3000 (206) 1600 (110) 1300 (89.5) 1200 (82.6) |

| 400 (204) 450 (232) 500 (260) 550 (287) 600 (315) |

4280 (294) 4130 (284) — — — |

4280 (294) 4130 (284) 3980 (274) 3870 (266) 3760 (259) |

100 (6.8) — — — — |

— — — — — |

1000 (68.9) 800 (55.1) 600 (41.3) 400 (27.5) 200 (13.7) |

| 650 (343) 700 (371) 750 (398) 800 (426) |

— — — — |

3700 (254) 3600 (248) 3520 (242) 3460 (235) |

— — — — |

— — — — |

— — — — |

| 850 (454) 900 (482) 950 (510) 1000 (537) |

— — — — |

3380 (232) 3280 (225) 3220 (221) 3030 (208) |

— — — — |

— — — — |

— — — — |

| 1050 (565) 1100 (593) 1150 (621) 1200 (648) |

— — — — |

3000 (206) 2685 (184) 2285 (157) 1715 (118) |

— — — — |

— — — — |

— — — — |

| (Inlet x Outlet) |

| 1/2″ MNPT x 1/2″ FNPT |

| 1/2″ FNPT x 1/2″ FNPT |

| 3/4″ MNPT x 1/2″ FNPT |

| (Inlet x Outlet) |

| 1/4″ MNPT x 1/4″ FNPT |

| 3/8″ MNPT x 3/8″ FNPT |

| 1/2″ MNPT x 1/2″ FNPT |

| 3/4″ MNPT x 3/4″ FNPT |

| 1/4″ MBSP x 1/4″ FBSP |

| 3/8″ MBSP x 3/8″ FBSP |

| 1/2″ MBSP x 1/2″ FBSP |

| 3/4″ MBSP x 3/4″ FBSP |

| Size | A | L |

|---|---|---|

| 1/4″ NPT | 37.3 | 14.3 |

| 3/8″ NPT | 37.3 | 14.3 |

| 1/2″NPT | 42.1 | 19.1 |

| 3/4″ NPT | 42.1 | 19.1 |

- Leak Testing

- Material Quality Testing

- Hydrostatic Testing

- Pilot Leakage Test

- Pilot Pressure Sensitivity

- Burst Pressure Testing

- Seat Leakage Test

- Pressure Measurement and Monitoring

- Safety and Protection

- Oil and Gas Industry

- Petrochemical Plants

- Power Generation

- HVAC Systems