View sizes and dimensions of Cryogenic globe valve

We are stockist and exporter of pneumatic globe control valve

Globe valve is an instrument which is used to control the flow of fluids in pipeline. These valves are widely used in landfills, chemical handling and swimming pools. Main advantages of using pneumatic globe control valve are its ability to good throttling and shut-off capabilities and these valves are easier to maintain. Fit-lok is 10 years old Globe valve manufacturer in India in wide range of sizes and pressure rating.

Steam globe valve manufactured by us are goes through various destructive and non destructive tastings which makes sure that our valves are of high quality and can be used for longer duration. Stainless steel globe valve are suitable for frequent operation and flow regulation. These valves are known for their high performance, longer functional life and compact design. We are top notch Bellow seal globe valve supplier in India and maintain ready stock for any small or large requirements of clients.

Cryogenic globe valve are critical component in many industrial applications and provides reliable and precise control over the flow of fluids. We are manufacturing and exporting globe valves using high quality material which we test on various parameters before using it, we also provide all the test certificates and third party inspection reports with our products. We can also provide high pressure globe valve in custom sizes or as per drawing on demand of customers. If you are looking to buy globe control valve feel free to contact us. These valves are available in different connection types such as Male to Male, Male to Female or Female to Female. We deliver High temperature globe valve with proper packing at clients location within committed time.

Table of content

- Globe valve Specification

- Different types of high pressure globe valve

- Globe valve price list

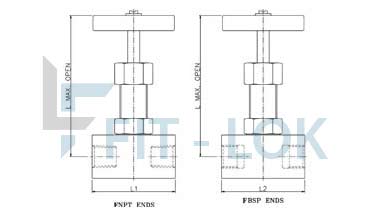

- Dimension of Globe Isolation Valves

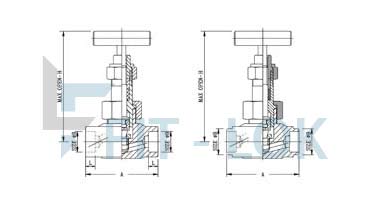

- Dimension of Globe Isolation Valve Single Ferrule Tube Ends

- Globe Shut off Valve Dimension

- What is the purpose of Globe control valve

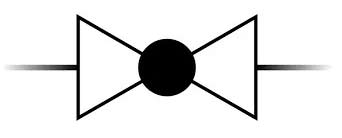

- Symbol of steam globe valve

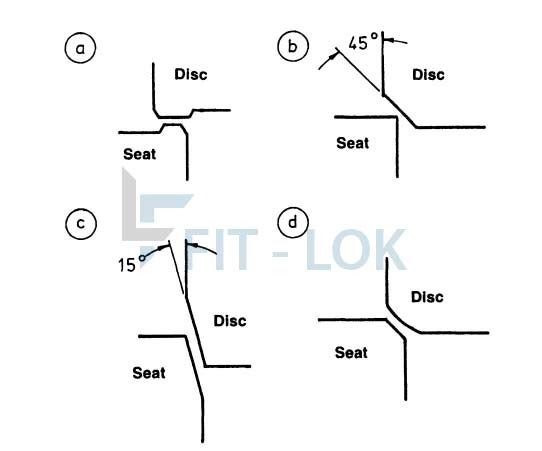

- Seating of SS globe valve

- Manufacturing standards of high temperature globe valve

- Parts and Material of construction of cryogenic globe valve

- Globe valve vs ball valve

- Globe valve advantages and disadvantages

- Quality and Testing of bellows globe valve

- Pneumatic globe control valve Applications

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Angle Globe Valve

Bellow Seal Globe Valve

Globe Control Valve

Cryogenic Globe Valve

Actuated Globe Valve

High Pressure Globe Valve

Price of High Pressure Globe Valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Cryogenic Globe Valve you can contact us on sales@fit-lok.com

Leading supplier of stainless steel globe valve in size range of DN 15 to DN 250

| SIZE | L1 | L | SIZE | L2 | L |

|---|---|---|---|---|---|

| 1/8″ FNPT | 46 | 90 | 1/8″ BSP | 46 | 90 |

| 1/4” FNPT | 58 | 95 | 1/4″ BSP | 50 | 95 |

| 3/8”FNPT | 60 | 88 | 3/8″ BSP | 60 | 88 |

| 1/2”FNPT | 75 | 94 | 1/2″ BSP | 75 | 94 |

| 3/4”FNPT | 84 | 104 | 3/4″ BSP | 84 | 104 |

| 1” FNPT | 135 | 129 | 1″ BSP | 135 | 129 |

| 1-1/4” FNPT | 150 | 161 | 1-1/4″ BSP | 150 | 161 |

| 1-1/2” FNPT | 166 | 187 | 1-1/2″ BSP | 160 | 187 |

| 2”FNPT | 225 | 220 | 2″ BSP | 225 | 220 |

| Series | Tube O.D. | L1 | L2 | L |

|---|---|---|---|---|

| PN 250 | 6 | 66 | 92 | 92 |

| 8 | 66 | 86 | 92 | |

| 10 | 66 | 90 | 92 | |

| 12 | 58 | 82 | 95 | |

| 15 | 84 | 114 | 95 | |

| 18 | 83 | 112 | 35 | |

| 22 | 79 | 112 | 95 | |

| 28 | 115 | 140 | 130 | |

| 35 | 129 | 164 | 166 | |

| 42 | 128 | 166 | 163 | |

| PN 400 | 6 | 66 | 96 | 92 |

| 8 | 66 | 90 | 92 | |

| 10 | 65 | 94 | 92 | |

| 12 | 65 | 94 | 93 | |

| 14 | 84 | 116 | 95 | |

| 16 | 83 | 118 | 95 | |

| 20 | 79 | 118 | 112 | |

| 25 | 106 | 146 | 130 | |

| 30 | 103 | 156 | 168 | |

| 38 | 147 | 197 | 161 |

| PIPE | B SIZE | L | A | H OPEN HT. |

|---|---|---|---|---|

| 1/2″ | 21.7 | 10.0 | 76 | 121 |

| 3/4″ | 27.0 | 13.0 | 85 | 125 |

| 1″ | 33.8 | 14.0 | 95 | 125 |

- Flow Regulation

- Throttling Control

- Pressure Control

- Maintaining Desired Temperature

- Flow Direction Control

- Preventing Overflows or Leaks

View diagram, symbol and working principle of steam globe valve

- ASME B16.34

- ASME B16.10

- API 6D / API 598

- MSS SP-25

- MSS SP-55

- BS 1868

- ASME B16.5

| Description | Material |

|---|---|

| Body Seat Ring | ASTM A182 Gr. F6a+HF |

| Disc Washer | 13% Cr. Steel |

| Body | ASTM A216 Gr. WCB |

| Disc | ASTM A216 Gr. WCB + 13% Cr. Steel |

| Stem | ASTM A182 Gr. F6a |

| Stud Nut | ASTM A194 Gr. 2H |

| Stud | ASTM A193 Gr. B7 |

| Disc Stem Nut | 13% Cr. Steel |

| Bonnet | ASTM A216 Gr. WCB |

| Gasket | ASTM A308 |

| Back-seat Bush | 13% Cr. Steel |

| Packing | Graphite with braided end rings |

| Eye Bolt | Cr. – Mo Steel |

| Gland Flange | ASTM A105 / ASTM A216 Gr. WCB |

| Gland | 13% Cr. Steel |

| Eye Bolt Nut | ASTM A194 Gr. 2H |

| Groove Pin | Steel |

| Washer | Steel |

| Yoke Bush | ASTM A439 Type D2 |

| Handwheel | Steel / Ductile Iron / Malleable Iron |

| Handwheel Nut | ASTM A563 Gr. B |

| Globe Valve | Ball Valve |

|---|---|

| Used for flow regulation | Used for isolation or on/off control |

| Provides more resistance to flow | Offers minimal flow resistance |

| Precise control of the flow rate | Provides quick and efficient on/off control |

Advantages

- Efficient and precise throttling

- Accurate flow control

Disadvantages

- High pressure

- More expensive

- Relatively low coefficient of flow

Bellow seal globe valve are more durable and less susceptible to damage

- Hydrostatic Testing

- Pilot Leakage Test

- Burst Pressure Testing

- Leak Testing

- Material Quality Testing

- Seat Leakage Test

- Pilot Pressure Sensitivity

- Petrochemical Plants

- Oil and Gas Industry

- Water Treatment Plants

- HVAC Systems

- Power Generation

- Food Industries