Reliable Alloy C276 Inline Check Valve Manufacturer in India

Hastelloy C22 Threaded Check Valve comes in wide range of threads such as NPT, BSPT, BSPP, JIC and UNF

Fit-lok is renowned Hastelloy Check Valve manufacturer in India which is known for its excellent corrosion resistance properties in the acidic medium. These valves are mainly contains nickel and molybdenum which are known for high temperature resistant materials. Alloy C276 Inline Check Valve are widely used in seawater, offshore drilling and petrochemical industries.

We are one of the leading Hastelloy C22 Threaded Check Valve supplier in India, which are manufactured with utmost precision using latest technology and machineries. These valves are available in different sizes, dimensions, specification, pressure rating and threads. Hastelloy Poppet Check Valve exhibit excellent durability, high tensile strength, superior surface finish and dimensional accuracy.

Fit-lok is stocking and supplying Alloy B2 One Way Check Valve to countries like USA, South Korea, Germany and UAE in different sizes and pressure rating as per demand of customers. We can manufacture these valves in custom sizes or dimensions on special demand. ASTM B574 UNS N10276 Non Return Check Valves can be hardened by heat treatment, and they are easily available in different finishes. Each Nickel C22 Instrumentation Check Valve are 100% tested on various destructive and non destructive test and are manufactured as per international standards.

We use high quality raw material to manufacture Hastelloy C276 Check Valve which are sourced from trusted suppliers, MTC and third party specification certificates are provided with these valves to ensure the quality and standards. Packaging of DIN 2.4819 Socket Weld Check Valve are done as per set packaging methods so that it should not get damaged in transportation.

Table of content

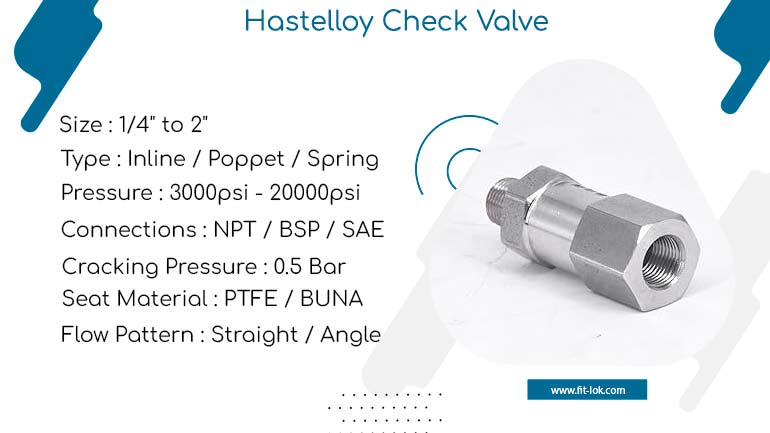

- Hastelloy Check Valve specification

- Alloy C276 Instrumentation Check Valve price list

- Various types of Hastelloy Check Valve

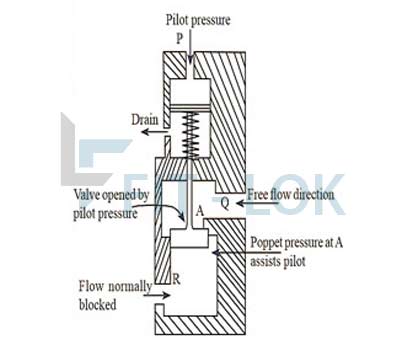

- Diagram of Hastelloy C276 Check Valve

- Hastelloy inline Check Valve chemical composition

- Hastelloy Spring Check Valve mechanical properties

- Hastelloy Poppet Check Valve equivalent grade

- Dimension of Hastelloy C22 Threaded Check Valve

- Alloy C22 Male to Male Check valve dimensions

- Average oxidation data of Nickel C276 Hydraulic Check Valve

- Features of DIN 2.4819 Socket Weld Check Valve

- Alloy C276 High Pressure Check Valve Applications

- Testing of Hastelloy B2 Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Price of Hastelloy Check Valve depends on several factors such as pressure rating, sizes, design type and grades. It normally range between 15$ to 80$ per piece. For updated price list of Alloy C276 Check Valve contact us at sales@fit-lok.com

Hastelloy Hydraulic Check Valve

Alloy C276 Inline Check Valve

Hastelloy C22 Nrv Valve

Nickel B2 Instrument Air Check Valve

Hastelloy C276 Non Return Valve

DIN 2.4819 Spring Check Valve

Alloy C22 Instrumentation Check Valve

Nickel C276 Poppet Check Valve

UNS N10276 Instrument Control Valve

| Grade | Ni | C | Mn | S | Co | Si | P | Fe | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| C22 | 50.015 min* | 0.010 max | 0.50 max | 0.02 max | 2.50 max | 0.08 max | 0.02 max | 2.00 – 6.00 | 20.00 – 22.50 | 12.50 – 14.50 |

| C276 | 50.99 min* | 0.010 max | 1.00 max | 0.03 max | 2.50 max | 0.08 max | 0.04 max | 4.00 – 7.00 | 14.50 – 16.50 | 15.00 – 17.00 |

| B2 | Bal | 0.02 max | 1.0 max | 0.03 max | 1.0 max | 0.1 max | 0.04 max | 2.0 max | 1.0 max | 26 – 30 |

| Element | Melting Point | Density | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| Hastelloy C22 | 1399 °C (2550 °F) | 8.69 g/cm3 | Psi – 45000 , MPa – 310 | Psi – 1,00,000 , MPa – 690 | 45 % |

| Hastelloy C276 | 1370 °C (2500 °F) | 8.89 g/cm3 | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

| Hastelloy B2 | 1370 °C (2500 ºF ) | 9.2 g/cm3 | Psi – 51000 , MPa – 350 | Psi – 1,10,000 , MPa – 760 | 40 % |

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS | GOST | OR |

|---|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | NiCr21Mo14W | NW 6022 | – | – |

| Hastelloy C276 | N10276 | 2.4819 | NiMo16Cr15W | NW 0276 | ХН65МВУ | ЭП760 |

| Hastelloy B2 | N10665 | 2.4617 | – | – | – | – |

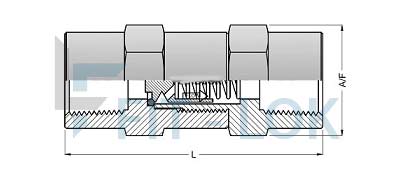

Leading stockist and supplier of Hastelloy Poppet Check Valve, Check dimensions of Alloy B2 One Way Check Valve

| Inlet End Connection | A/F (mm) | L (mm) | |

|---|---|---|---|

| Inlet | Outlet | ||

| 1/8″ | 1/8″ | 19.0 | 50 |

| 1/4″ | 1/4″ | 19.0 | 60 |

| 3/8″ | 3/8″ | 22.0 | 60 |

| 1/2″ | 1/2″ | 32.0 | 84 |

| 3/4″ | 3/4″ | 35.0 | 84 |

| 1″ | 1″ | 40.5 | 99 |

Nickel C22 Instrumentation Check Valve are manufactured in size range of 1/8″ to 2″

| Inlet End Connection | A/F (mm) | L (mm) | |

|---|---|---|---|

| Inlet | Outlet | ||

| 1/8″ | 1/8″ | 19.0 | 54 |

| 1/4″ | 1/4″ | 19.0 | 63 |

| 3/8″ | 3/8″ | 19.0 | 63 |

| 1/2″ | 1/2″ | 22.0 | 73 |

| 3/4″ | 3/4″ | 32.0 | 99 |

| 1″ | 1″ | 35.0 | 115 |

Hastelloy C276 Check Valve have excellent corrosion resistance properties, Reliable dealer of DIN 2.4819 Socket Weld Check Valve in wide range of sizes

| Test Temperature, °F(°C) |

Average Oxidation Rate per 100-hour test period | |||

|---|---|---|---|---|

| 100 hours,intermittent mils mm |

100 hours,continuous mils mm |

|||

| 2000 (1093) | 2.88 | 0.073 | 1.62 | 0.041 |

| 1900 (1038) | 0.18 | 0.005 | 0.22 | 0.006 |

| 1800 (982) | 0.11 | 0.003 | 0.11 | 0.003 |

- Resistance to Chlorides

- Ability to Withstand High Temperatures

- Prevents Backflow

- Long Service Life

- High Strength

- Compatibility with Aggressive Chemicals

- Easy to Weld and Fabricate

- Chemical Processing

- Oil & Gas Industry

- Power Generation

- Water Treatment Plants

- Marine Applications

- Pulp and Paper Industry

- Refineries

- Food and Beverage Industry

- Hydrostatic Pressure Testing

- Leakage Testing

- Backflow Testing

- Seat Tightness Test

- Functional Testing

- Visual Inspection

- Corrosion Resistance Testing

- Vibration Testing

- Hardness Testing