Are you looking for stainless steel hexagon reducing nipple manufacturer in India

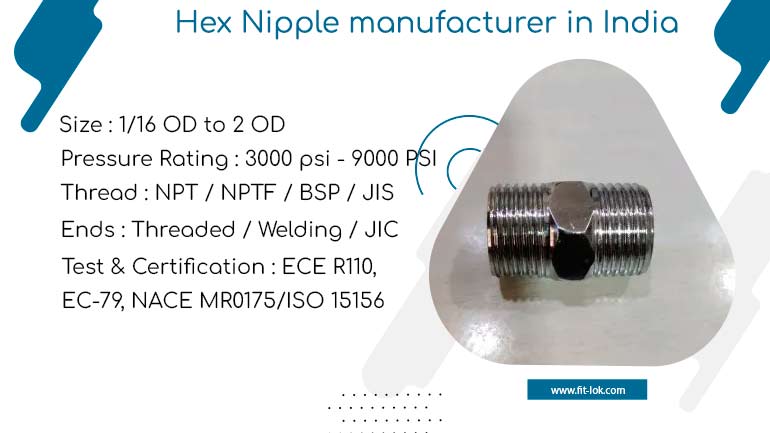

A hex nipple is a type of pipe fitting used to connect two identically sized pipes or fittings. It has a hexagonal body in the centre and male threads on both ends. The hexagonal form of the “hex nipple” provides a convenient surface for tightening with a wrench. Hex nipples come in a variety of sizes and materials to meet the needs of diverse fluid systems.

Reducing hex nipple provide a convenient solution for joining two pipes of the same diameter

The hex nipple’s male threads on both ends allow it to screw into the female threads of the pipes or fittings, essentially linking them together. The hexagonal body allows for simple installation and tightening with a wrench, resulting in a dependable and efficient connection. Long hex nipples are longer in length, giving more threads for a more secure connection in some applications. Hex nipples connect pipes or fittings of the same size quickly and efficiently, easing fluid system construction.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

reducing hex nipple

npt hex nipple

bsp hex nipple

ss 304 hex nipple

hexagon reducing nipple

brass hexagon nipple

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

When sourcing bsp hex nipple and galvanized hex nipple, it’s crucial to partner with reputable suppliers who offer a wide selection of sizes and materials to meet your specific project requirements

- Power generation

- Textile industry

- Brewing equipment

- Industrial machinery

- Construction and architecture

NPT reducing nipple are typically specified by the pipe thread sizes at both ends

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

We keep ready stock of brass hexagon nipple

Packaging of Hex Nipple

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

How does a Hex Nipple facilitate the connection between two threaded pipes or fittings, and what advantages does it offer in terms of ease of installation and disassembly?

A Hex Nipple is a pipe fitting used to connect two threaded pipes or fittings together, providing a secure and reliable connection that can be easily installed or disassembled using a wrench on the hexagonal surfaces.

What are the common applications for Hex Nipples, and how do they contribute to the efficient flow of fluids or gases in various industries?

Hex Nipples have various applications in industries such as plumbing, oil and gas, chemical processing, and HVAC systems, where they enable the seamless flow of fluids or gases between pipe sections or components.

What factors should be considered when selecting a Hex Nipple

When selecting a Hex Nipple, important factors to consider include ensuring material compatibility with the fluid or gas being conveyed, matching the thread type and size to the existing pipe fittings, and considering the pressure rating and temperature requirements of the application to ensure a proper and durable connection.