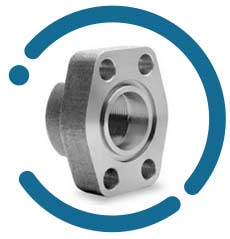

Biggest Stainless Steel High Pressure SAE Flange manufacturer in India

Hydraulic systems rely heavily on High Pressure SAE flange connections. To create a full flange connection you need a flange with an O-ring groove and a flat flange component. Bolts made of Metric or UNC standards attach the flanges while O-rings or SAE profile rings make the seal.

Specialized designs help these flanges bear significant pressure levels. Specialized carbon steel stainless steel and titanium materials form these flanges to withstand stress and prevent failure under extreme pressure levels. High pressure SAE flanges need gaskets O-rings and metal seals to keep a watertight seal when under strong pressure.

Top notch supplier of Ermeto Original High Pressure Hydraulic Flanges

High-pressure SAE flanges have two main purposes in addition to their core function as pipe connectors. These components help protect system components and operations run better overall. The oil and gas sector plus aerospace and chemical processing depend on high-pressure flanges that need to perform reliably while maintaining safety requirements. These standards help the flange handle all the operational challenges including pressure, vibrations, thermal growth, and mechanical strain. Inspection of materials and production processes helps ensure high-pressure SAE flanges avoid failure.

Table of content

- High Pressure SAE Flange Specification

- Different types of Stainless Steel High Pressure SAE Flange

- Dimensions of Ermeto Original High Pressure Hydraulic Flanges

- Torque Table of High Pressure SAE Flange

- Features of Stainless Steel High Pressure SAE Flange

- Ermeto Original High Pressure Hydraulic Flanges Application

| Type | High pressure SAE Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

High Pressure SAE Flange

Stainless Steel High Pressure SAE Flange

Ermeto Original High Pressure Hydraulic Flanges

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Leakage Prevention

- Versatility

- Standardized Design

- High Pressure Capability

- Material Variety

- Steel Mills

- Hydraulic Presses

- Industrial Hydraulics

- Injection Moulding Machinery

- Aluminium Die-Casting Machinery

- Sintering Machinery