Trust us as one of the finest Nickel Alloy 800 Male Run Tee manufacturers in India

Incoloy 800 Tube Fittings are available in wide range of sizes from a leading manufacturer and supplier. We manufacture these fittings in various specifications, keeping in mind the changing needs of industries, as part of our dedication to meeting customer requirements. Our commitment to meeting national, international, and predefined quality requirements enables the production of high-quality Nickel Alloy 800 Male Run Tee.

To ensure the highest quality standards, we manufacture UNS N08800 high pressure compression fittings in accordance with national, international, and established quality norms. We can make fittings with precise dimensions and excellent tolerances thanks to our cutting-edge technology and modern machinery. These innovative production procedures ensure that Nickel Alloy 800 male connectors are standardised and perfect.

Competitive pricing for reliable UNS N08800 high pressure compression fittings supply in India

These fittings have a high tensile strength and are extremely mechanically stable and durable. ASTM B564 UNS N08800 flare fittings strength allows them to endure high-pressure conditions, assuring consistent performance.

800 Incoloy double ferrule fittings have a good resistance to chloride stress corrosion cracking. As a result, they are suited for applications involving chloride-rich conditions.

The ASTM SB 564 UNS N08800 bulkhead union are designed to provide exceptional corrosion resistance in sulphur-containing and acidic environments. This characteristic ensures their usefulness for essential industrial applications involving exposure to harsh conditions.

Table of content

- Incoloy 800 tube fittings Specification

- Types of Incoloy 800 compression fittings

- Alloy 800 instrumentation fittings chemical composition

- UNS N08800 high pressure compression fittings mechanical composition

- DIN 1.4876 ferrule fittings equivalent grade

- Size chart of Nickel Alloy 800 male connector

- Incoloy Alloy 800 hydraulic fittings Pressure rating

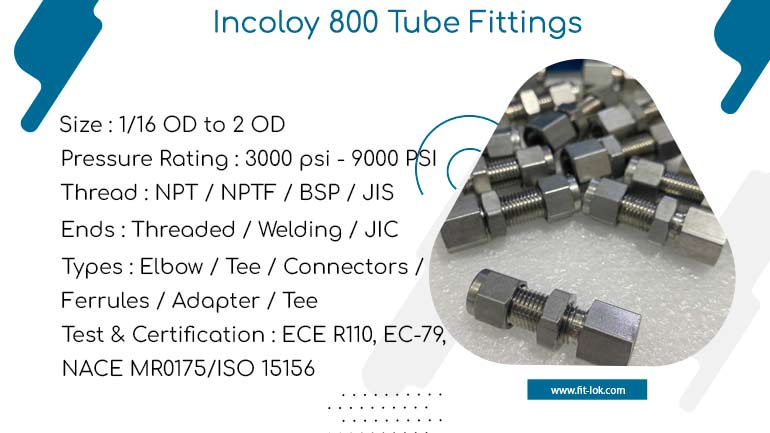

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

|---|---|

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

DIN 1.4876 ferrule fittings

Nickel Alloy 800 male connector

Incoloy Alloy 800 hydraulic fittings

ASTM B564 UNS N08800 flare fittings

Inconel 800 pneumatic fittings

Alloy 800 instrumentation tube fittings

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60? | 0.15 – 0.60? |

We are proud to offer DIN 1.4876 ferrule fittings that serve the needs of both instrumentation and industrial sectors.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | – | X8NiCrAlTi32-21 | XH32T |

Source Nickel 800 male connector at competitive prices from the exporter.

| Tube OD (in) | Thread Size (in) | Hex Flat (in) |

|---|---|---|

| 1/16 | 1/16 | 0.31 |

| 1/8 | 1/8 | 0.38 |

| 3/16 | 1/8 | 0.38 |

| 1/4 | 1/4 | 0.46 |

| 5/16 | 1/4 | 0.46 |

| 3/8 | 3/8 | 0.54 |

| 1/2 | 1/2 | 0.71 |

| 5/8 | 1/2 | 0.71 |

| 3/4 | 3/4 | 0.83 |

| 7/8 | 3/4 | 0.83 |

| 1 | 1 | 1.02 |

| Dash Size | Nominal Tube/Pipe Size | SAE100R2 | National Pipe Tapered Fuel (NPTF) | National Pipe Straight Mechanical (NPSM) | JIC 37° Flare Hydraulic SAE J514 | Flareless Compression SAE J514 | ||

| Male | Female | Female Swivel | Male | Female Swivel | ||||

| -02 | 1/8″ | 10000 | 5000 | 6000 | ||||

| -04 | 1/4″ | 5000 | 9500 | 4500 | 5000 | 8500 | 5500 | 6000 |

| -05 | 5/16″ | 4250 | 8500 | 5000 | ||||

| -06 | 3/8″ | 4000 | 8000 | 3500 | 4000 | 7000 | 4000 | 6000 |

| -08 | 1/2″ | 3500 | 6000 | 3500 | 3500 | 6000 | 4000 | 6000 |

| -10 | 5/8″ | 2750 | 5500 | 3000 | 5000 | |||

| -12 | 3/4″ | 2250 | 5000 | 3000 | 3500 | 4000 | 3000 | 4500 |

| -14 | 7/8″ | 2000 | 4000 | 3000 | ||||

| -16 | 1″ | 2000 | 4000 | 2500 | 3000 | 3500 | 2500 | 4000 |

| -20 | 1-1/4″ | 1625 | 3000 | 2000 | 2000 | 3500 | 2000 | |

| -24 | 1-1/2″ | 1250 | 2000 | 1500 | 1500 | 2000 | 1500 | |

| -32 | 2″ | 1125 | 2000 | 1400 | 1500 | 1250 | 1250 | |

Explore the thermal expansion and scratch resistance properties of our Alloy 800 hydraulic fittings for long-lasting performance.

Application of 800 Incoloy double ferrule fittings

- HVAC systems

- Water treatment

- Marine applications

- Aerospace industry

- Automotive applications

Packaging of DIN 1.4876 ferrule fittings

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is the temperature range for Incoloy 800 tube fittings?

Incoloy 800 tube fittings can typically operate in temperatures ranging from cryogenic (-423°F/-253°C) up to 1800°F (982°C), providing excellent high-temperature strength and oxidation resistance.

Are DIN 1.4876 ferrule fittings suitable for corrosive environments?

Yes, DIN 1.4876 ferrule fittings exhibit excellent resistance to corrosion in various acidic and aqueous environments, making them suitable for applications involving corrosive media.

Can 800 Incoloy double ferrule fittings be used in high-pressure applications?

Yes, 800 Incoloy double ferrule fittings have good mechanical properties and can withstand high-pressure conditions, making them suitable for demanding industrial applications.

What sizes are available for ASTM B564 UNS N08800 flare fittings?

ASTM B564 UNS N08800 flare fittings are available in various sizes, including commonly used sizes such as 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, and 1″ among others, catering to different installation requirements.

What are the common applications of Alloy 800 instrumentation fittings?

Alloy 800 instrumentation fittings are commonly used in industries such as chemical processing, power generation, and heat exchangers, where resistance to corrosion, high temperatures, and pressure is crucial.