We are one of the biggest manufacturer of Alloy 625 manifold control valve in India

Get in touch for assistance for buying UNS N06625 manifold tuning valves

What is Inconel Manifold Valve

Inconel manifold valve is manufactured from inconel alloys and designed to use for regulating, controlling, or isolating the flow of fluids or gases within a piping system. These valves are highly corrosion-resistant and can withstand higher temperatures which makes them suitable choice for demanding industrial applications.

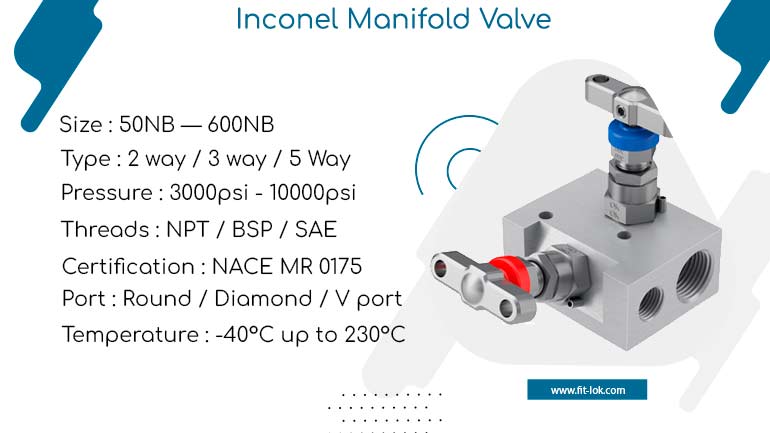

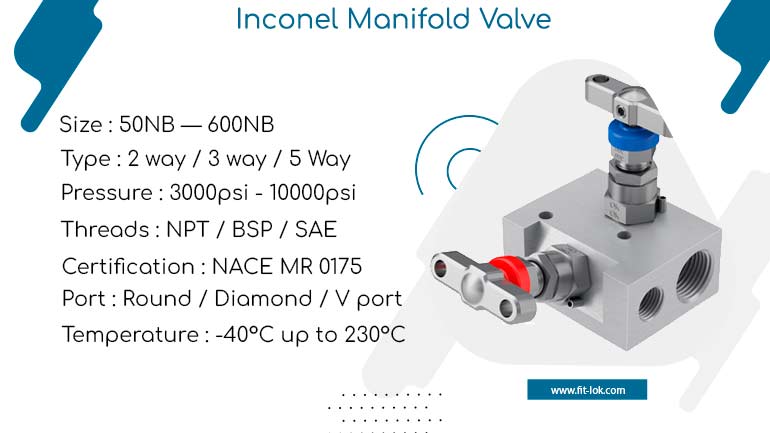

Inconel manifold valve specification

| Size |

50NB — 600NB |

| Pressure |

150PS1 |

| Temperature |

0 Deg C – 1200 Deg C. |

| Body , Chest |

Solid One piece casting of Cast Iron Fg 260, Cast Steel Gr WCB ,CF8,CF8M. |

| Seat |

Integral to Body, Soft, Optional. |

| Gate |

AISI SS 304,316,316L,317,317L |

| Screw Spindle |

AISI SS 410,304,316. |

| Nut |

Brass |

| Yoke |

Plate type of MS . |

| Gland Follower |

Cast Iron , Cast steel , Ductile Iron ,CF8,CF8M. |

| Hand Wheel |

Cast Iron , Cast steel , Ductile Iron |

| Gland Packing |

PTFE , PTFE Impregnated |

| Ends |

Lugged |

| Port |

STANDARD [Round], Optional V Port, Diamond Port,. |

Inconel manifold heat control valve chemical composition

| Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

Cr |

| Inconel 600 |

0.15 max |

1.00 max |

0.50 max |

0.015max |

0.50 max |

6.00 – 10.00 |

72.00 min |

14.00 – 17.00 |

| Inconel 601 |

0.10 max |

1.0 max |

0.5 max |

0.015 max |

1.0 max |

Balance |

58.0 – 63.0 |

21.0 – 25.0 |

| Inconel 625 |

0.10 max |

0.50 max |

0.50 max |

0.015 max |

– |

5.0 max |

58.0 min |

20.0 – 23.0 |

| Inconel 718 |

0.08 max |

0.35 max |

0.35 max |

0.015 max |

0.30 max |

– |

50.00 – 55.00 |

17.00 – 21.00 |

Inconel alloy manifold control valve Mechanical properties

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Inconel 600 |

8.47 g/cm3 |

1413 °C (2580 °F) |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

40 % |

| Inconel 601 |

8.1 g/cm3 |

1411 °C (2571 °F) |

Psi – 80,000 , MPa – 550 |

Psi – 30,000 , MPa – 205 |

30 % |

| Inconel 625 |

8.4 g/cm3 |

1350 °C (2460 °F) |

Psi – 1,35,000 , MPa – 930 |

Psi – 75,000 , MPa – 517 |

42.5 % |

| Inconel 718 |

8.2 g/cm3 |

1350 °C (2460 °F) |

Psi – 1,35,000 , MPa – 930 |

Psi – 75,000 , MPa – 482 |

45 % |

Equivalent grade of Inconel manifold tuning valves

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

| Inconel 600 |

2.4816 |

N06600 |

NCF 600 |

NA 13 |

МНЖМц 28-2,5-1,5 |

NC15FE11M |

NiCr15Fe |

| Inconel 601 |

2.4851 |

N06601 |

NCF 601 |

NA 49 |

XH60BT |

NC23FeA |

NiCr23Fe |

| Inconel 625 |

2.4856 |

N06625 |

NCF 625 |

NA 21 |

ХН75МБТЮ |

NC22DNB4M |

NiCr22Mo9Nb |

| Inconel 718 |

2.4668 |

N07718 |

– |

– |

– |

– |

– |

Pressure Rating Of Inconel 600 manifold valve

| Operating pressure |

Max.: 700 bar (10,153 psi) |

Size Chart of Alloy 625 manifold check valve

| Connections |

C |

End Connection |

LG |

THK |

Top/Bottom Connection |

Width |

| 4 |

1.38 |

HF9 |

5.26 |

1.5 |

HF6 |

2.63 |

| 6 |

1.38 |

HF9 |

7.76 |

1.5 |

HF6 |

2.63 |

| 8 |

1.38 |

HF9 |

10.26 |

1.5 |

HF6 |

2.63 |

| 10 |

1.38 |

HF9 |

12.76 |

1.5 |

HF6 |

2.63 |

| 14 |

1.38 |

HF9 |

17.76 |

1.5 |

HF6 |

2.63 |

Inconel 625 manifold valves typically ranges between $200 to $1,500 USD per valve, For specific size and up to date price you can contact us on sales@fit-lok.com.