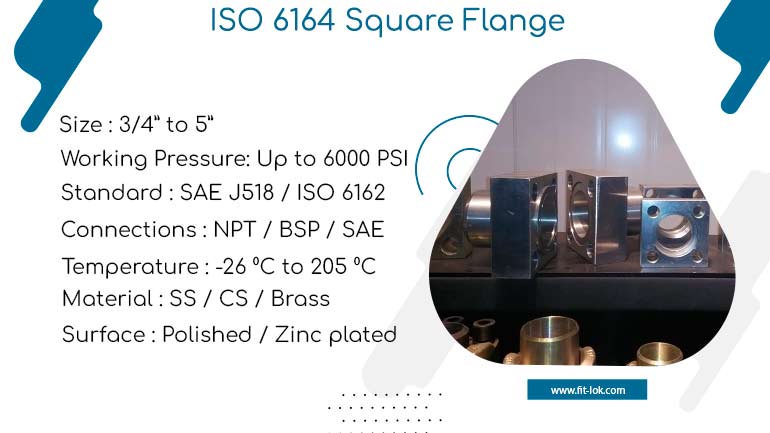

Leading ISO 6164 Square Flange manufacturer in India

ISO 6164 Flanges are made according to the ISO 6164 norms that define dimension and performance for hydraulic systems up to operating pressures of 400 bar or 5800 psi. ISO 6164 Square Flange are highly recommended due to their non-corrosive, easy to install, and guaranteed long life nature the products are demanded in construction industries, mining industries, oil and gus industries and power industries.

ISO 6164 Sch 160 flanges are a special design to enable easy removal and addition to avoid necessitating dismantling during maintenance or replacement. They provide a bolt hole and mounting that will give a secure connection and will not easily come loose. ISO 6164 flanges are accurately computed and passed through through a machining process that makes the surface of the flanges smooth in design hence provoking enhanced sealing performance, especially when in union with O-rings or other sealing devices. To enhance the protection measures, these flanges are mostly covered with zinc plating, phosphate or powder coating. This finish also gives better protection against corrosion therefore makes the flanges appropriate for external and marine use.

We are supplier and stockist of ISO 6164 Sch 160 flanges in Mumbai

ISO 6164 400 Bar flanges are produced in various standard to suit the different hydraulic systems used in organizations. Standard sizes include from DN13 (1/2 inch) to DN76 (3 inches) or greater depending upon the capacity of the system it serves. The bolt hole configurations also meet IS016164 to implement better tendons and compatibility with other pieces. These patterns enable one to attach and align to other segments safely. These ISO 6164 flanges are made for the hydraulic apparatus used in low and high pressure reaching up to 400 bar or 5800 psi. This makes them ideal for high stress applications where machinery is frequently in use such as; Construction equipment, mining machinery, and industrial hydraulics.

The ISO 6164 Square Flange are used in industries that demand pressure hydraulic systems essential in operations. We ensure that ISO 6164 flanges are readily available in standard sizes and sizes that clients specifically ask for in the market. Fit-Lok is ISO 6164 Flanges manufacturer and employs modern technology and superior quality materials for creating long-lasting and high efficient flanges for ISO.

Table of content

| Type | ISO 6164 Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

ISO 6164 Flange

ISO 6164 Sch 160 flanges

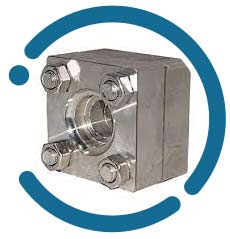

ISO 6164 Square Flange

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Versatility

- Material Variety

- Standardized Design

- High Pressure Capability

- Leakage Prevention

- Building Machinery

- Agricultural Machinery

- Forestry Machinery

- Paper Processing

- Mobile Hydraulics

- Lifting and Material Handling Equipment