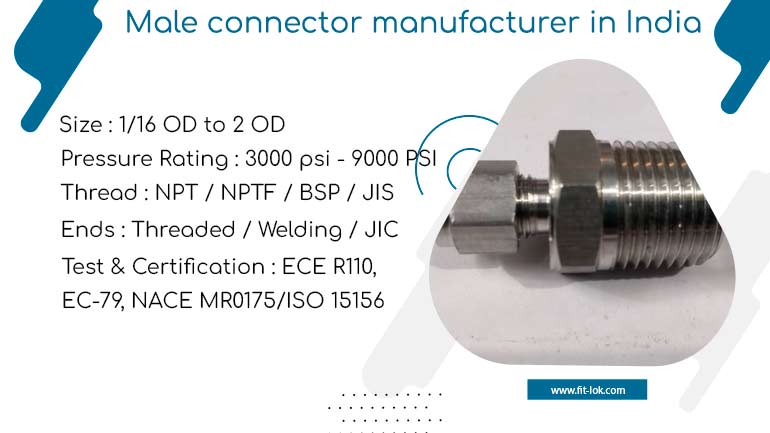

We take pride in being a leading Brass BSP male connector manufacturer in India

A male connector’s basic role is to safely link two components in a fluid system. By putting the connector’s male-threaded end into the female-threaded opening, a reliable connection is formed that avoids fluid leakage and provides smooth fluid flow. Male connections are critical in establishing a continuous and efficient fluid channel inside the system.

We are a renowned stockist of brass male connector

Reducing male connectors feature various diameters on each end, allowing them to join different-sized pipes or fittings. Male connectors are adaptable and can be used to join a variety of pipe types and fittings in fluid systems. Male connectors’ seamless connections reduce flow constraints and pressure drops, resulting in efficient fluid flow. Male connectors manufactured of high-quality materials are durable and resilient, making them appropriate for a variety of applications.

Table of content

| Types | NPT, ISO/BP, SAE/MS, AN, weld ends |

| Size | 1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm, High-Pressure – 1/8 to 9/16 in. |

| Pressure Ratings | Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar), High-Pressure – Up to 60 000 psig (4134 bar). |

| Temperature Ratings | Up to 1000°F (537°C) |

| Thread | Thread BSPT, UNF, NPT, BSP, |

Male Connector

bsp male connector

brass male connector

bulkhead male connector

din male connector

double male connector

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

Check our updated bulkhead male connector price list for competitive pricing and cost-effective solutions

- Food processing equipment

- Beverage industry

- Pharmaceutical equipment

- Chemical processing

- Petrochemical industry

We ensure timely delivery and excellent customer support for all your din male connector needs

- Pitting Resistance Test

- Micro and Macro Test

- Hardness Test

- Flaring Test

- IGC Test

- Flattening Test

- Chemical Analysis

Trust us as your preferred distributor of high-quality double male connector products

Packaging of Male connector

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is a Male connector and how does it function in a fluid or gas system?

A Male connector is a type of fitting used to join two components in a fluid or gas system, typically consisting of a male threaded end that mates with a corresponding female threaded connection to create a secure and leak-free connection.

What are the common types and sizes of Male connectors available in the market?

Male connectors come in various types and sizes, including straight connectors, elbow connectors, and tee connectors, with different thread sizes such as NPT (National Pipe Thread) or metric threads, allowing for compatibility with different systems and components.

What are the key considerations when selecting a Male connector for specific applications, such as material compatibility, pressure rating, and connection method?

When selecting a Male connector, key considerations include ensuring material compatibility with the fluid or gas being conveyed, checking the pressure rating of the connector to match the system requirements, and considering the connection method, such as compression, push-to-connect, or soldering, based on the specific application and installation preferences.