Count on us as a trusted UNS N02200 Bulk Head Union manufacturer in India

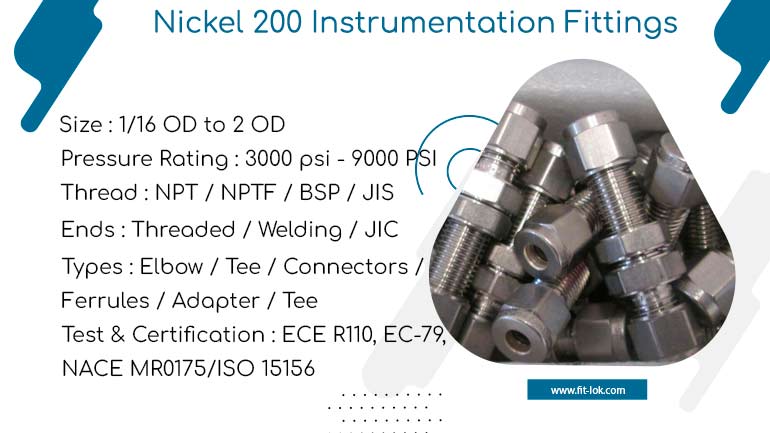

Nickel 200 Instrumentation Fittings are intended to offer dependable and precise connections in instrumentation systems. We provide a comprehensive choice of UNS N02200 Bulk Head Union in various sizes, types, and specifications as part of our dedication to providing great products. Our emphasis on quality and client satisfaction has made us a reliable source in the business.

We have been an effective choice for sectors that require precise and dependable instrumentation solutions due to our commitment to excellence and customer satisfaction. Our large selection of nickel alloy 200 compression fittings demonstrates our commitment to supplying high-quality goods.

You can purchase UNS N02200 hydraulic fittings and Ni200 flare fittings from the supplier at reasonable prices.

ASTM B160 UNS N02200 ferrule fittings are essential components of instrumentation systems in a variety of sectors. These Ni200 flare fittings are specifically engineered to form precise and leak-free connections, ensuri ng accurate fluid measurement and management. These fittings are intended for use in instrumentation systems to make precise connections. Ni 200 double ferrule fittings precise alignment and tight sealing contribute to the overall precision and reliability of instrumentation systems.

UNS N02200 pneumatic fittings have strong temperature stability, allowing them to function well in high-temperature applications. This property ensures that it can be used in a variety of industrial environments. Quality is prioritized at all stages of the manufacturing process. To ensure that our pure nickel 200 bulkhead union meets the highest quality standards, we adhere to severe quality control measures and industry standards. We are able to offer fittings of extraordinary quality and performance due to our cutting-edge production facilities and professional personnel.

Table of content

- Nickel 200 tube fittings Specification

- Types of Nickel alloy 200 compression fittings

- ASTM B160 N02200 male connector chemical composition

- Alloy 200 instrumentation fittings mechanical composition

- ASTM B160 UNS N02200 ferrule fittings equivalent grade

- Size chart of UNS N02200 hydraulic fittings

- Pure nickel 200 bulkhead union Pressure rating

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

|---|---|

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

Alloy 200 instrumentation fittings

ASTM B160 UNS N02200 ferrule fittings

UNS N02200 hydraulic fittings

Ni200 flare fittings

DIN 2.4066 single ferrule fittings

Ni 200 double ferrule fittings

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

High-performance DIN 2.4066 single ferrule fittings and pure nickel 200 bulkhead union manufacturer for medium pressure applications

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

We provide Ni 200 double ferrule fittings and nickel 200 pneumatic fittings suitable for a wide range of applications, including both instrumentation and industrial settings.

| Tube OD (in) | Thread Size (in) | Hex Flat (in) |

|---|---|---|

| 1/16 | 1/16 | 0.31 |

| 1/8 | 1/8 | 0.38 |

| 3/16 | 1/8 | 0.38 |

| 1/4 | 1/4 | 0.46 |

| 5/16 | 1/4 | 0.46 |

| 3/8 | 3/8 | 0.54 |

| 1/2 | 1/2 | 0.71 |

| 5/8 | 1/2 | 0.71 |

| 3/4 | 3/4 | 0.83 |

| 7/8 | 3/4 | 0.83 |

| 1 | 1 | 1.02 |

| Dash Size | Nominal Tube/Pipe Size | SAE100R2 | National Pipe Tapered Fuel (NPTF) | National Pipe Straight Mechanical (NPSM) | JIC 37° Flare Hydraulic SAE J514 | Flareless Compression SAE J514 | ||

| Male | Female | Female Swivel | Male | Female Swivel | ||||

| -02 | 1/8″ | 10000 | 5000 | 6000 | ||||

| -04 | 1/4″ | 5000 | 9500 | 4500 | 5000 | 8500 | 5500 | 6000 |

| -05 | 5/16″ | 4250 | 8500 | 5000 | ||||

| -06 | 3/8″ | 4000 | 8000 | 3500 | 4000 | 7000 | 4000 | 6000 |

| -08 | 1/2″ | 3500 | 6000 | 3500 | 3500 | 6000 | 4000 | 6000 |

| -10 | 5/8″ | 2750 | 5500 | 3000 | 5000 | |||

| -12 | 3/4″ | 2250 | 5000 | 3000 | 3500 | 4000 | 3000 | 4500 |

| -14 | 7/8″ | 2000 | 4000 | 3000 | ||||

| -16 | 1″ | 2000 | 4000 | 2500 | 3000 | 3500 | 2500 | 4000 |

| -20 | 1-1/4″ | 1625 | 3000 | 2000 | 2000 | 3500 | 2000 | |

| -24 | 1-1/2″ | 1250 | 2000 | 1500 | 1500 | 2000 | 1500 | |

| -32 | 2″ | 1125 | 2000 | 1400 | 1500 | 1250 | 1250 | |

Check out the impact resistance and flame retardant properties of our UNS N02200 compression fittings and alloy 200 tube fittings for added safety.

Application of ASTM B160 N02200 male connector

- Water treatment

- HVAC systems

- Automotive applications

- Aerospace industry

- Marine applications

Packaging of Alloy 200 instrumentation fittings

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What is the corrosion resistance of ASTM B160 N02200 male connector?

ASTM B160 N02200 male connector offer excellent resistance to a wide range of corrosive environments, including acids, alkaline solutions, and neutral salts.

Can Alloy 200 instrumentation fittings be used in high-temperature applications?

Yes, Alloy 200 instrumentation fittings can be used in high-temperature applications up to approximately 600°C (1112°F) due to their good thermal stability and low thermal expansion.

Are ASTM B160 UNS N02200 ferrule fittings suitable for cryogenic applications?

Yes, ASTM B160 UNS N02200 ferrule fittings can withstand extremely low temperatures and are commonly used in cryogenic applications such as liquefied gas storage and transportation.

What are the available sizes for UNS N02200 hydraulic fittings?

UNS N02200 hydraulic fittings are available in various sizes, including commonly used sizes such as 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, and 1″ among others, catering to different installation requirements.