We take pride in being a leading Ni male / female elbow manufacturer in India

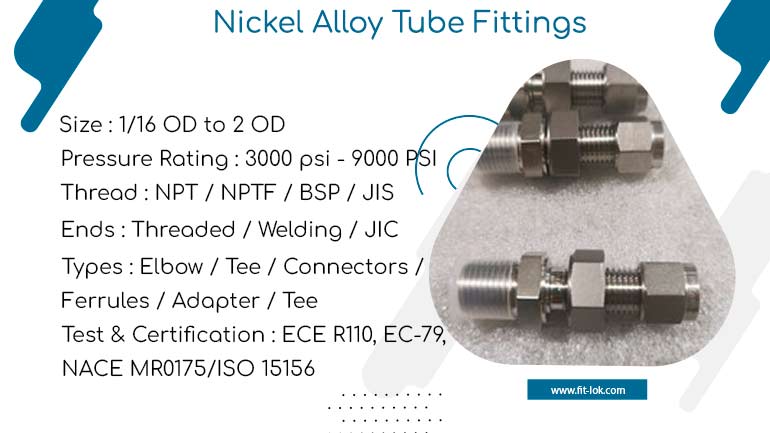

Fit-lok is a reliable manufacturer and supplier of Nickel Compression Tube Fittings. We meet the needs of our valued customers by offering both customized and non-customized Fittings. Our high-quality nickel alloy tube fittings can be used in a variety of industrial applications. These fittings, which have exceptional corrosion resistance and great mechanical strength, play an important role in vital industrial activities. They provide long-lasting support and efficiency throughout wide temperature ranges, making them a dependable solution for a variety of industrial applications.

Efficient exporter of nickel alloy bulkhead union with easy installation and enhanced cost efficiency

These high nickel alloy male connectors have exceptional corrosion resistance, making them appropriate for usage in a variety of settings, including acidic and alkaline conditions. Nickel alloy ferrule fittings corrosion resistance ensures their lifespan and dependability in important industrial applications. Furthermore, Ni alloy flare fittings have a high mechanical strength, which adds to their longevity and robustness. The fittings are excellent for rigorous industrial activities since they can tolerate high-pressure situations while maintaining structural integrity.

Pure nickel alloy pneumatic fittings are well-known for their durability across a wide temperature range. They can operate reliably in both high- and low-temperature applications, ensuring constant performance in a variety of industrial conditions. They are suitable for important operations in various industries due to their exceptional corrosion resistance, mechanical strength, and efficiency over a wide temperature range. They ensure dependable fluid and gas transmission, which improves the overall performance and safety of industrial systems.

Table of content

- Nickel alloy tube fittings Specification

- Types of Nickel compression fittings

- high nickel alloy male connector chemical composition

- Nickel based alloy instrumentation fittings mechanical composition

- Nickel alloy ferrule fittings equivalent grade

- Size chart of High nickel hydraulic fittings

- Ni alloy flare fittings Pressure rating

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

|---|---|

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

nickel alloy ferrule fittings

high nickel hydraulic fittings

Ni alloy flare fittings

super nickel alloy single ferrule fittings

pure nickel double ferrule fittings

pure nickel alloy pneumatic fittings

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

With our comprehensive range of nickel alloy compression tube fittings, we cater to the diverse requirements of both instrumentation and industrial applications.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Learn about the water absorption and UV resistance properties of our Ni alloy flare fittings for extended lifespan.

| Tube OD (in) | Thread Size (in) | Hex Flat (in) |

|---|---|---|

| 1/16 | 1/16 | 0.31 |

| 1/8 | 1/8 | 0.38 |

| 3/16 | 1/8 | 0.38 |

| 1/4 | 1/4 | 0.46 |

| 5/16 | 1/4 | 0.46 |

| 3/8 | 3/8 | 0.54 |

| 1/2 | 1/2 | 0.71 |

| 5/8 | 1/2 | 0.71 |

| 3/4 | 3/4 | 0.83 |

| 7/8 | 3/4 | 0.83 |

| 1 | 1 | 1.02 |

| Dash Size | Nominal Tube/Pipe Size | SAE100R2 | National Pipe Tapered Fuel (NPTF) | National Pipe Straight Mechanical (NPSM) | JIC 37° Flare Hydraulic SAE J514 | Flareless Compression SAE J514 | ||

| Male | Female | Female Swivel | Male | Female Swivel | ||||

| -02 | 1/8″ | 10000 | 5000 | 6000 | ||||

| -04 | 1/4″ | 5000 | 9500 | 4500 | 5000 | 8500 | 5500 | 6000 |

| -05 | 5/16″ | 4250 | 8500 | 5000 | ||||

| -06 | 3/8″ | 4000 | 8000 | 3500 | 4000 | 7000 | 4000 | 6000 |

| -08 | 1/2″ | 3500 | 6000 | 3500 | 3500 | 6000 | 4000 | 6000 |

| -10 | 5/8″ | 2750 | 5500 | 3000 | 5000 | |||

| -12 | 3/4″ | 2250 | 5000 | 3000 | 3500 | 4000 | 3000 | 4500 |

| -14 | 7/8″ | 2000 | 4000 | 3000 | ||||

| -16 | 1″ | 2000 | 4000 | 2500 | 3000 | 3500 | 2500 | 4000 |

| -20 | 1-1/4″ | 1625 | 3000 | 2000 | 2000 | 3500 | 2000 | |

| -24 | 1-1/2″ | 1250 | 2000 | 1500 | 1500 | 2000 | 1500 | |

| -32 | 2″ | 1125 | 2000 | 1400 | 1500 | 1250 | 1250 | |

Buy super nickel alloy single ferrule fittings at affordable rates from the stockist.

Application of pure nickel double ferrule fittings

- Aerospace industry

- Marine applications

- Water treatment

- HVAC systems

- Automotive applications

Packaging of Ni alloy flare fittings

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What are the common types of Nickel Alloy tube fittings available?

Common types of Nickel Alloy tube fittings include compression fittings, flare fittings, and bite-type fittings, among others, catering to different system requirements.

Are nickel alloy ferrule fittings suitable for high-temperature applications?

Yes, nickel alloy ferrule fittings exhibit excellent high-temperature strength and resistance to thermal expansion, making them suitable for demanding high-temperature environments.

What are the advantages of using Ni compression fittings in corrosive environments?

Ni compression fittings offer exceptional corrosion resistance to a wide range of corrosive media, including acids, alkalis, and seawater.

Can pure nickel double ferrule fittings be used in cryogenic applications?

Yes, pure nickel double ferrule fittings have good cryogenic properties and can operate at extremely low temperatures, making them suitable for cryogenic applications.

What industries commonly utilize Ni alloy flare fittings?

Ni alloy flare fittings find applications in industries such as chemical processing, oil and gas, aerospace, and power generation, where corrosion resistance, high-temperature strength, and reliability are crucial.