Biggest Code 62 O Ring Flange manufacturer in India

O-Ring Face SAE flanges are manufactured to fine limits to guarantee that dimensions and tolerances are tightly controlled. It affords a safe and standardized coupling of pipes, valves, pumps, and almost any other hydraulic assemblies or part, thus reducing the likelihood of having leakage in the hydraulic system. O-Ring Face flanges are designed in such a way that guarantee interchangeability with hydraulic systems of many manufacturers.

Normally used in production of carbon steel, stainless steel or alloy steel, these flanges are highly resistant to tension, corrosion, and abrasion. This makes the construction strong to withstand the tough environments in order to have long lasting and efficient performance. Due perhaps to vibration, this O-ring design reduces cases of fluid leakage in hydraulic systems and increases their lifespan.

To guard against corrosion and environmental, Code 62 O Ring Flange can be finished with zinc plating, phosphate coating powder coating or other finishes that may enhance their protective coatings. In applications where flanges are welded the SAE O Ring Flange are available with beveled edges to enhance the weld depth and strength. This provides the firm and strong joint so much desirable for hydraulic system call high pressure hydraulic system.

O-ring Face SAE Flange are designed for pressure applications, more often up to 6 000 psi (400 bar). These compounds have a high pressure capability making them suitable for use in hydraulic systems where retaining a safe seal is important. It is important to note that the planed pressure rating of SAE O-Ring Face flanges is constant in temperature.

Table of content

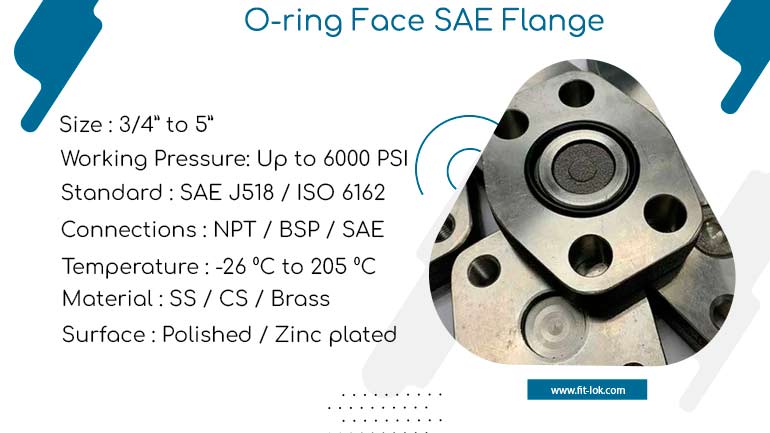

| Type | O-ring Face SAE Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

O-ring Face SAE Flange

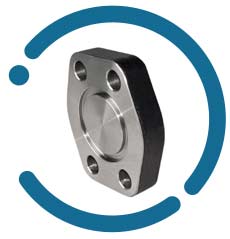

Code 62 O Ring Flange

SAE O Ring Flange

| SAE Flange Size | ID (Nominal) | ID (Actual) | OD (Nominal) | OD (Actual) | Section (Nominal) | Section (Actual) |

|---|---|---|---|---|---|---|

| 1/2 | 3/4 | .734 | 1 | 1.012 | 1/8 | .139 |

| 3/4 | 1 | .984 | 1 1/4 | .262 | 1/8 | .139 |

| 1 | 1 5/16 | 1.296 | 1 9/16 | 1.574 | 1/8 | .139 |

| 1 1/4 | 1 1/2 | 1.484 | 1 3/4 | 1.762 | 1/8 | .139 |

| 1 1/2 | 1 7/8 | 1.859 | 2 1/8 | 1.137 | 1/8 | .139 |

| 2 | 2 1/4 | 2.234 | 2 1/2 | 2.512 | 1/8 | .139 |

| 2 1/2 | 2 3/4 | 2.734 | 3 | 3.012 | 1/8 | .139 |

| 3 | 3 3/8 | 3.359 | 3 5/8 | 3.637 | 1/8 | .139 |

| 3 1/2 | 3 7/8 | 3.859 | 4 1/8 | 4.137 | 1/8 | .139 |

| 4 | 4 3/8 | 4.359 | 4 5/8 | 4.637 | 1/8 | .139 |

| 5 | 5 3/8 | 5.359 | 5 5/8 | 5.637 | 1/8 | .139 |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Corrosion Resistance

- Interchangeability

- Easy Installation

- Temperature Resistance

- Sealing Options

- Agricultural Machinery

- Forestry Machinery

- Paper Processing

- Mobile Hydraulics

- Building Machinery

- Lifting and Material Handling Equipment