Contact us if you are looking for Hydraulic pressure gauge snubber Manufacturer in India

A pressure gauge snubber is a device used to minimize sharp force or motion by regulating the force or rate of an engine. Also called Dead ends, Pressure snubbers help to calm pressure pulses and spikes so as to increase the service life, and ease pressure gauge readings in rough environments. Available in porous, piston or throttling styles, these units can processes a wide variety of media including air and other gaseous media, water, steam, gasoline and oils. Fit-Lok is leading Pressure Gauge Snubber manufacturer in India in wide range of sizes.

They help to shield pressure measurements instruments from the influences of vibrations in a system which is pressurized with pulsations for example positive displacement utility such as pump or compressors. The pressure snubber functions with the goal of regulating variations in pressure. Snubbers do not change the pressure of the process, but decrease the pulsation in the line and therefore, increases the stability of the gauge reading, and in addition, expends the working life of the gauge.

Ask for latest Price list of Bsp Threaded Pulsation Snubber

A fluid filled gauge can do the same thing but with some pressure systems, they are so intense that a snubber has to be incorporated. Special attention should be made when it comes to the measurement on high frequency and short duration pressure surges; and one should avoid having snubbers because they always slow the operation of the safety systems.

Table of content

- Pressure Gauge Snubber specification

- Different types of Gauge Snubber

- Npt Thread Pulsation Snubber dimensions

- Types of gauge snubbers

- Price list of pressure gauge snubber

- Pressure rating of Hydraulic pressure gauge snubber

- How to select and operate pressure gauge snubber

- Temperature Rating of adjustable gauge snubber

- How does a pressure gauge snubber work

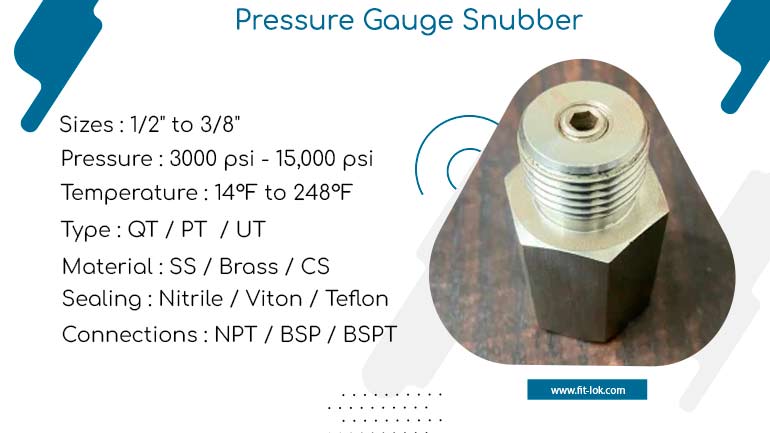

| SIZE | 1/8″ TO 3/4″ (STANDARD SIZE- 1/2″ M X F ) |

| CONNECTION | THREADED |

| THREADS | NPT, BSPP, BSPT, METRIC |

| BODY SHAPE | HEXAGON |

| SEAL | VITON, PTFE, BUNA |

| PRESSURE RATING | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI |

| MEDIA | HYDRAULIC OIL, AIR, WATER, GAS, STEAM, HOT WATER , COLD WATER , SEA WATER , CHEMICAL |

| MEDIA TEMPERATURE | (-50* C TO 350*C ) RANGE AS PER PRESSURE |

| BODY TYPE | BAR STOCK |

| MATERIAL | SS 316, SS 304, BRASS, SS 316 TI, CS, COPPER, DUPLEX, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L & TITANIUM, ALL OTHER ALLOYS |

Pressure Gauge Snubber

Hydraulic pressure gauge snubber

Bsp Threaded Pulsation Snubber

| Pressure Rating | B – Length | A – Length | C – Length | HEX | D – Hex |

|---|---|---|---|---|---|

| 60000 psi 4137 bar |

2.50 in 63.50 mm |

3.36 in 85.34 mm |

0.50 in 12.70 mm |

1.19 in 30.15 mm |

0.63 in 16.00 mm |

| 60000 psi 4137 bar |

2.50 in 63.50 mm |

4.05 in 102.87 mm |

0.50 in 12.70 mm |

1.19 in 30.15 mm |

0.63 in 16.00 mm |

| 60000 psi 4137 bar |

2.13 in 54.1 mm |

3.68 in 93.47 mm |

1.50 in 38.10 mm |

1.19 in 30.15 mm |

0.75 in 19.05 mm |

- Porous disc type snubber

- Adjustable pressure gauge snubber

- Piston-type snubber

- Liquid filled pressure gauges and snubbers

| Product | Price |

| Brass pressure gauge snubber, 1/4 in NPT, Filter, 1,500 psi | $15.74 Per piece |

| Stainless Steel Pressure Gauge Snubber, 1/2 in NPT, 15,000 psi | $160.48 Per piece |

| Copper Alloys | Stainless Steel | |||

|---|---|---|---|---|

| Thread | Bar | PSI | Bar | PSI |

| G ⅛ | 400 | 6000 | 400 | 6000 |

| G ¼ | 600 | 8600 | 1000 | 15000 |

| G ⅜ | 600 | 8600 | 1000 | 15000 |

| G ½ | 1000 | 15000 | 2500 | 36000 |

| M10 X 1 | 400 | 6000 | 400 | 6000 |

| M12 X 1.5 | 400 | 6000 | 400 | 6000 |

| M20 X 1.5 | 1000 | 15000 | 2500 | 36000 |

| ⅛ NPT, R ⅛ | 400 | 6000 | 400 | 6000 |

| ¼ NPT, R ¼ | 600 | 8600 | 1000 | 15000 |

| ⅜ NPT, R ⅜ | 600 | 8600 | 1000 | 15000 |

| ½ NPT, R ½ | 1000 | 15000 | 1600 | 23000 |

| 7/16-20 UNF | 400 | 6000 | 800 | 12000 |

- Construction material

- Snubber chemical compatibility

- Dynamic load cycles

- Temperature

- Pressure suitability

- Price

| Temperature Rating | 14°F to 248°F (-10°C to 120°C) |

The snubber reduces the rate at which the fluid or the gas gets to the gauge. This minimizes the impact of pressure fluctuations and pulsations. The snubber is intended to permit through only quasi-static pressure changes. This orderly manner of reading results to a more stable reading as was observed when comparing the two devices.