Leading 3000 PSI 90 deg buttweld flange manufacturer in India

SAE 90 degree buttweld flange are widely-used elements in assemblies of fluid and gases where it is necessary to change the direction by 90 degrees. These are some of the SAE Flanges taken from the series of many SAE flanges that are used in casing leak proof and strong connection in hydraulic, piping as well as mechanical sectors.

The most characteristic feature of these flanges is their capability of sharp orientation change in flow of fluid or gaseous media, which is achieved due to the 90-degree bend in the flange. This enables the product to be fitted in systems where space or position demands a right-angle connection. The structure of the flange is built such that it can be joined and welded perfectly to the pipe without the need for additional support. The butt weld process also guarantees a leak-proof connection system that would well suit high pressure applications.

3000 PSI 90 deg buttweld flange are widely employed in different industries such as, oil and gas industry, automotive industry, chemical industry, and water treatment industry. They are particularly suitable in applications where orientation is necessary, such as pipework, exhausts or in any other fluid or gaseous distribution networks. SAE 90 deg buttweld flange are normally bored with an agreed bevel or weld preparation whereby it can fit to be welded to pipes or other parts. This helps assure that the connection issequential and sound, which builds up a strong and sustainable technology.

For specific applications, Stainless steel 90 deg buttweld flange may be made in other sizes apart from those listed above by request. This is typical in systems that require different flange sizes than are obtainable in the market, the hydraulic or piping system will have its own dimensions. SAE 90-degree butt weld flanges are available in standard pressure classes of 150, 300, 400, 600, 900, 1500, 3000. These pressures can easily be accommodated by flanges manufactured from conventional materials such as carbon steel or stainless steel.

Table of content

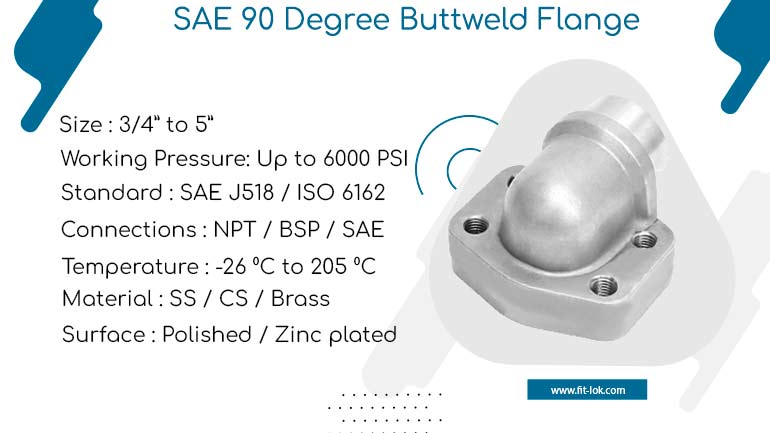

| Type | SAE 90 degree buttweld flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE 90 degree buttweld flange

3000 PSI 90 deg buttweld flange

Stainless steel 90 deg buttweld flange

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Standardized Design

- High Pressure Capability

- Leakage Prevention

- Versatility

- Material Variety

- Industrial Hydraulics

- Steel Mills

- Hydraulic Presses

- Injection Moulding Machinery

- Aluminium Die-Casting Machinery

- Sintering Machinery