We are renowned SAE b blanking plate manufacturer in India

SAE blanking plate are very important in hydraulic systems and are used to plug hydraulic ports, passages, or connections for a specific amount of time or for ever. In maintenance, testing or for isolating a specific system, the blanking plates provide a leak-proof blanking which enables integrity of function of the fluid power systems in industries like oil and gas, construction, manufacturing and automotive.

SAE blanking plates are known also as SAE cover plates or blocking plates – these ones are flat and solid components used to block off the hydraulic ports or connections when they are not needed. While other flanges are used to interconnect system parts blanking plates are developed for the specific purpose of sealing hydraulic systems or equipment. They are normally secured on mating flanges or manifolds by a set of high tensile bolts and are usually used in conjunction with O-rings or sealing gasket to create a seal which is Liability free.

Are you looking for SAE c blanking plate supplier in Mumbai

These plates are manufactured as per SAE J518 international compatibility of hydraulic systems. SAE b blanking plate are produced in varied sizes and pressures and therefore can be used to meet specific hydraulic systems and needs.

The precision design and application of sealing elements guarantee a high-reliable leakage-tight connection to improve the safety performance and efficiency of hydraulic systems. SAE blanking plates can be employed for short term disablement of ports during maintenance, or used for port disablement for good for ports that are not required. These make them easy to install and dismantle thus minimizing time taken in removing the system so as to service it.

SAE c blanking plate are an inalienable component for sealing the unchecked hydraulic ports or disconnecting the system segments in service or modernization. The overall construction, high pressure compatibility, and conformity to the SAE standards clearly make them popular among hydraulic engineers.

Table of content

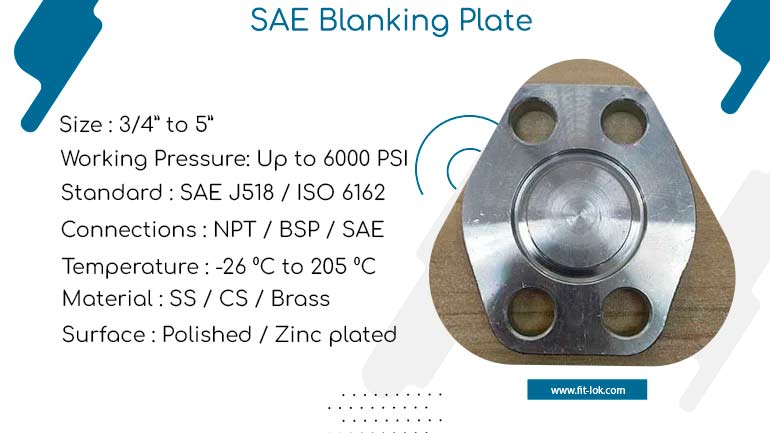

| Type | SAE blanking plate |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE blanking plate

SAE b blanking plate

SAE c blanking plate

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Corrosion Resistance

- Interchangeability

- Sealing Options

- Easy Installation

- Temperature Resistance

- Industrial Hydraulics

- Injection Moulding Machinery

- Steel Mills

- Hydraulic Presses

- Aluminium Die-Casting Machinery

- Sintering Machinery