SAE blank flange manufacturer in India

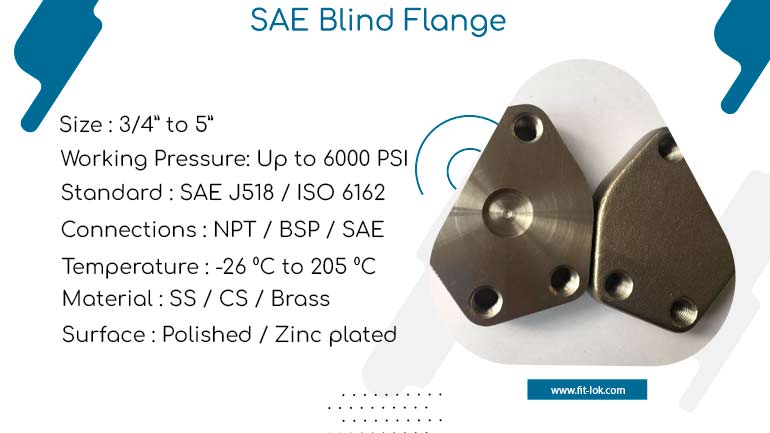

SAE Blind Flange is a flanged fitting without a central, through hole to accommodate a member to be connected, and provides a closure to the end of a hydraulic line or pipe. SAE Blind Flanges are different from other flanges that connect the pipes because it serves as termination or closure where the hydraulic system becomes closed. These flanges are generally screwed on other compatible flanges or some hydraulic accessory, while O-ring groove is planned for provisions of sealing members to prevent leakage. SAE Blind Flanges are available in carbon, stainless, and alloy grade giving a high pressure holding capability.

Fit-Lok is reliable SAE Blind Flange manufacturer in India in wide range of sizes and pressure rating. There is no central bore in the SAE blank flange and is best used to seal hydraulic lines. With an O-ring groove it is possible to guarantee a maximum of tightness and minimal leakage, either for high pressure applications. These flanges are easy to site and release; making it easier to maintain the pipe systems and also for altering the system as well.

SAE code 61 blind flange are available between DN 13 (1/2”) and DN 127 (5”) and operating pressures up to 350 bar

SAE code 61 blind flange are specifically useful because they close the ends of a hydraulic system, thus, are useful whenever the system needs to be split in certain sections for repair, inspection or expansion. The mechanical features of this product include the manufacture from materials that provide strong construction and sealing making the connection leak proof to enhance system efficiency and safety. Specialised for withstanding pressures these flanges are perfect to use in hydraulic services. We are supplying SAE code 61 blind flange in different countries such as Kuwait, Colombia and Algeria.

Although Class 3000 SAE Blind Flanges come with multiple benefits for car manufacturing, its material and size should be chosen carefully. There are few important things which should be taken into consideration for selecting a blind flange like operating pressure, temperature, type of fluid in services and OR environment condition. To ensure a tight and leak-free seal, a proper fit of the mating faces and use of suitable gaskets or O-rings are of paramount importance.

Table of content

| Type | SAE blind flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE blind flange

SAE blank flange

SAE code 61 blind flange

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Easy Installation

- Temperature Resistance

- Interchangeability

- Sealing Options

- Corrosion Resistance

- Injection Moulding Machinery

- Aluminium Die-Casting Machinery

- Sintering Machinery

- Industrial Hydraulics

- Steel Mills

- Hydraulic Presses