Class 3000 SAE Butt Weld On Flange manufacturer in India

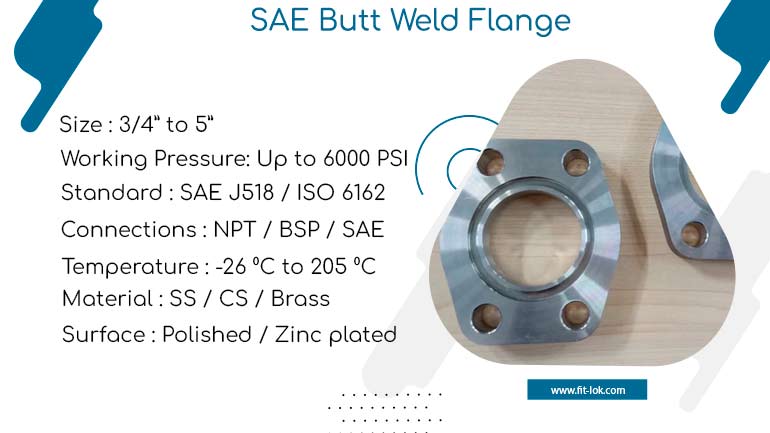

SAE Butt Weld Flanges are vital attributes of high pressure hydraulic systems due to their capability of forming strong and long lasting joint for pipes or tubes. These flanges have also been designed in compliance with the SAE standards such that they would be able to offer a reliable performance, together with the ability to last longer in the given operating conditions. Fit-lok is one of the trusted SAE Butt Weld Flanges manufacturer in India in size range of 1/4 ” NB up to 5 ” NB. Because the SAE Butt Weld Flange can easily fit into the numerous types of fluid power systems, construction, marine, oil and gas, automobile, and manufacturing industries are the most common users of the SAE Butt Weld Flanges.

This design reduces trailing edge turbulence and pressure drop to provide best usable hydraulic system. Class 3000 SAE Butt Weld On Flange are manufactured to conform to SAE J518 specifications, due to which they can fit most hydraulic systems. Butt weld design is ideal for services that are necessitating high degrees of pressure and need an airtight sealing technique. We are exporting Class 3000 Buttweld Flange in Nigeria, Indonesia, Malaysia and UAE.

Buy Hydraulic SAE Butt Weld Flange directly from supplier in Mumbai

Hydraulic SAE Butt Weld Flange is not mechanically fastened to the pipe or tube, instead it is welded to the pipe and forms a reinforce ring with the pipe, capable of supporting high pressure and mechanical loads. These flanges are of high pressure that will suit hydraulic systems up to 6,000 psi and even more. The correspondence of the SAE Butt Weld Flanges possesses the great wearing, corrosive and fatigue resistance that makes them suitable for long term usage.

Despite the benefits of SAE Butt Weld Flanges there is a need to ensure that they are installed rightly and the right material is used. The type and size of the flange depends on pressure and temperature in the operation, type of fluid that will be subject to the flange and working environment. Also, welding process is required for correct joint and it must be done with professional to avoid the problem like a crack or leakage.

Table of content

| Type | SAE Butt Weld Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE Butt Weld Flange

Class 3000 SAE Butt Weld On Flange

Hydraulic SAE Butt Weld Flange

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Versatility

- Standardized Design

- Leakage Prevention

- Material Variety

- High Pressure Capability

- Agricultural Machinery

- Forestry Machinery

- Paper Processing

- Mobile Hydraulics

- Building Machinery

- Lifting and Material Handling Equipment