Are you looking for SAE code 61 socket weld flange manufacturer in India

We are stockist and exporter of SAE 3000 socket weld flange in wide range of sizes and pressure rating

Table of content

- SAE socket weld flange Specification

- Different types of SAE code 61 socket weld flange

- Dimensions of SAE 3000 socket weld flange

- Dimensions of SAE 6000 socket weld flange

- Torque Table of SAE socket weld flange

- Features of SAE code 61 socket weld flange

- SAE 3000 socket weld flange Application

- SAE Code 61 Socket Weld Flange Surface condition

| Standard | ISO 6162 |

| Type | SAE socket weld flange |

| Size | 1/2″-5″ |

| Pressure Rating | 3000PSI / 6000PSI |

| Material | 20# / 45# / Q345 / Q345B / Q345D steel / Stainless steel 304 / Stainless steel 316 |

| Code | Code 61 and Code 62 |

| Manufacturing Process | Forging / Casting |

| Connection | Socket Weld |

| Body Type | Forged / Bar Stock |

| Flange Accessories | Bolt / Washer / Nut / O-ring |

| O-ring Materal | Nitrile / Buna 90 Shore / Viton 85-90 Shore |

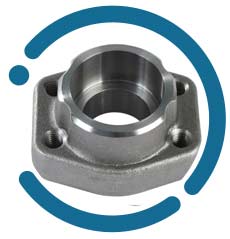

SAE socket weld flange

SAE code 61 socket weld flange

SAE 3000 socket weld flange

| Size (inch) | Dimension | Bolt | ||||||||||

| A | B | D | C | F | E | H | G | K | I | M | U | |

| 1/2″ | 21.6 | 13 | 54 | 38.1 | 46 | 17.48 | 16 | 36 | 9 | 19 | M8x30 | 5/16×11/4 |

| 3/4″ | 27.2 | 19 | 65 | 47.63 | 50 | 22.23 | 18 | 36 | 11 | 19 | M10x35 | 3/8×11/2 |

| 3/4″ | 25.3 | 19 | 65 | 47.63 | 5o | 22.23 | 18 | 36 | 11 | 19 | M10x35 | 3/8×11/2 |

| 1″ | 34 | 25 | 70 | 52.37 | 55 | 26.19 | 18 | 38 | 11 | 19 | M10x35 | 3/8×11/2 |

| 1 1/4″ | 42.8 | 32 | 79 | 58.72 | 68 | 30.18 | 21 | 41 | 11.5 | 22 | M10x40 | 7/16×11/2 |

| 1 1/4″ | 38.3 | 32 | 79 | 58.72 | 68 | 30.18 | 21 | 41 | 11.5 | 22 | M10x40 | 7/16×11/2 |

| 1 1/2” | 48.6 | 38 | 93 | 69.85 | 78 | 35.71 | 25 | 45 | 13.5 | 24 | M12x45 | 1/2×13/4 |

| 1 1/2″ | 50.5 | 38 | 93 | 69.85 | 78 | 35.71 | 25 | 45 | 13.5 | 24 | M12x45 | 1/2×13/4 |

| 2″ | 61 | 51 | 102 | 77.77 | 9o | 42.88 | 25 | 45 | 13.5 | 26 | M12x45 | 1/2×13/4 |

| 2 1/2″ | 76.6 | 63 | 114 | 88.9 | 105 | 50.8 | 25 | 50 | 13.5 | 30 | M12x45 | 1/2×13/4 |

| 3″ | 90.5 | 73 | 134 | 106.38 | 124 | 61.93 | 27 | 50 | 17 | 34 | M16x50 | 5/8×2 |

| 3 1/2″ | 103 | 89 | 152 | 120.65 | 136 | 69.85 | 27 | 48 | 17 | 34 | M16x50 | 5/8×2 |

| 4″ | 115.5 | 89 | 162 | 130.18 | 146 | 77.77 | 27 | 48 | 17 | 34 | M16x50 | 5/8×2 |

| 5″ | 142 | 120 | 184 | 152.4 | 180 | 92.08 | 29 | 50 | 17 | 28 | M16x55 | 5/8×2 |

| Size (inch) | Dimension | Bolt | ||||||||||

| A | D | B | C | E | H | F | G | K | I | M | U | |

| 1/2″ | 21.6 | 56 | 13 | 40.49 | 18.24 | 16 | 48 | 36 | 8 | 19 | M8x30 | 5/16×11/4 |

| 3/4″ | 27.2 | 71 | 19 | 50.8 | 23.8 | 21 | 55 | 35 | 11 | 22 | M10x35 | 3/8×11/2 |

| 1″ | 34 | 81 | 25 | 57.15 | 27.76 | 25 | 65 | 42 | 13 | 22 | M12x45 | 7/16×13/4 |

| 1 1/4″ | 42.8 | 95 | 32 | 66.68 | 31.75 | 27 | 78 | 45 | 15 | 25 | M14x50 | – |

| 1 1/4″ | 42.8 | 95 | 32 | 66.68 | 31.75 | 27 | 78 | 45 | 13.5 | 25 | – | 1/2×1 3/4 |

| 1 1/4″ | 38.3 | 95 | 32 | 66.68 | 31.75 | 27 | 78 | 45 | 15 | 25 | M14x50 | – |

| 1 1/2″ | 48.6 | 112 | 38 | 79.38 | 36.5 | 30 | 94 | 50 | 17 | 28 | M16x55 | 5/8×2 |

| 1 1/2″ | 50.5 | 112 | 38 | 79.38 | 36.5 | 30 | 94 | 50 | 17 | 28 | M16x55 | 5/8×2 |

| 2″ | 61 | 134 | 51 | 96.82 | 44.45 | 37 | 114 | 65 | 21 | 32 | M20x70 | 3/4×21/2 |

| 2 1/2″ | 76.6 | 18o | 63 | 123.83 | 58.73 | 45 | 152 | 80 | 25 | 30 | M24x85 | – |

| 3″ | 90.5 | 208 | 73 | 152.4 | 71.43 | 55 | 178 | 90 | 32 | 30 | M30x100 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Standardized Design

- Material Variety

- High Pressure Capability

- Versatility

- Leakage Prevention

- Paper Processing

- Mobile Hydraulics

- Lifting and Material Handling Equipment

- Building Machinery

- Agricultural Machinery

- Forestry Machinery

- Zinc coated (white)

- Phosphated (black)

- Blank + oiled

- Untreated oxidation

- Nickle plated

- Yellow Galvanized zinc