SAE 6162 split flanges manufacturer in India

SAE Split Flange is one of the crucial elements of the fluid power system and offers excellent parameters of the connection in hydraulic and pneumatic systems. These SAE 6162 split flanges have been designed to the requirement of SAE J518 standards and these flanges are used widely in many sectors including construction, automotive, agricultural and in marine fields. They are very reliable, durable and have high rate of efficiency, characteristic that makes them suitable for use on areas of high pressure fluid transfer. We are one of the reliable SAE Split Flange manufacturer in India and can fulfill any small or large orders as per requirement of clients.

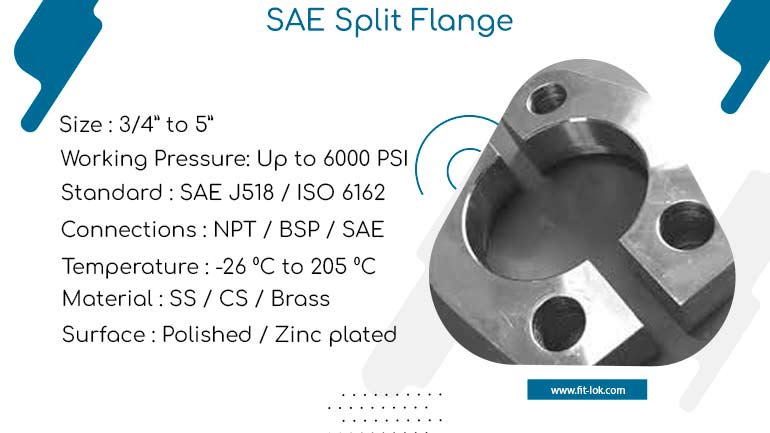

SAE Split Flange is a hydraulic fitting in which two halves are joined by bolts in order to clamp a hose, pipe or tube to a port or manifold. The flange halves hold an O-ring or sealing gasket, making sure that the bolts will be tightened down securely. These flanges are manufactured for usage in situations where pressure may be as high as 6,000 psi and boasts excellent results in challenging conditions. These constructions can be easily installed, maintained and substituted that makes them more preferable than welded or threaded ones.

We keep ready stock of SS split flange with adapter in wide range of sizes

Stainless steel split flange are produced to meet SAE J518 requirement hence they can fit most hydraulic system platforms. This simplifies the integration mechanism with the existing systems because of the applied standardization. Supported by high pressure hydraulic circuits, these flanges are capable to provide the comfort operating conditions in industrial mechanisms and vehicles.

The split design means both halves are easily separable for maintenance, repairs or replacement without having to do much disassembly. It compact structure and the O-ring groove designed in the flange can be ensured which makes that connection without gaps even at different pressure and temperature variations.

Table of content

| Type | SAE Split Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE Split Flange

SAE 6162 split flanges

SS split flange with adapter

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Standardized Design

- High Pressure Capability

- Leakage Prevention

- Versatility

- Material Variety

- Paper Processing

- Mobile Hydraulics

- Building Machinery

- Agricultural Machinery

- Forestry Machinery

- Lifting and Material Handling Equipment