Leading SAE T-Block Flange Connectors manufacturer in India

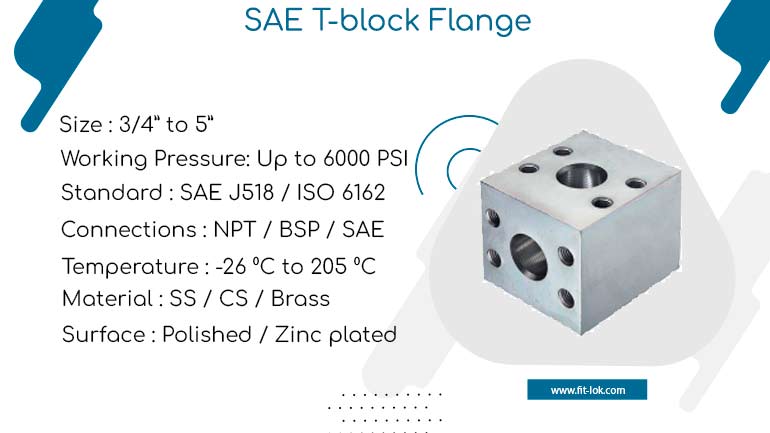

SAE T-block flanges are versatile and reliable components which are widely used for hydraulic and fluid systems to make branch connections. Design of these flanges makes the branched hydraulic systems possible through the T-shaped section. They allow closed and dense coupling where many lines have to be incorporated into a single system safely. These flanges are manufactured according to SAE J518 or ISO 6162 series and can work in conjunction with numerous hydraulic components. This minimize integration and make it easy to use the media in different parts of the world.

The external and internal surfaces of SAE T-Block Flange Connectors are accurately finished through machining. This improves the sealing capacity and minimize the possibilities for fluids seepage. In a stainless steel T-block flanges passivation process is applied to enhance resistance to rust and oxidation, which ensures reliable performance in corrosive environments. Depending on the application, flanges may be coated with specialized materials to enhance durability, such as PTFE coatings for chemical resistance or galvanization for additional protection.

Refer sizes and dimensions of 3000 PSI SAE T-Block Flange

As a manufacturer and supplier of SAE T Block Companion Flange, we can manufacture these flanges in any size that is appropriate for a particular project especially in areas of compatibility with especial hydraulic systems. Parts can be accurately produced to the required dimensions such as thickness, boring sizes and bolt circle dimensions to meet modern high performance system requirements. 3000 PSI SAE T-Block Flange are intended for hydraulic applications where high pressure values are expected, and operating pressures available are varied, and provided in a range of 3000 psi thru 6000 psi, with differences in reference to materials and sizes of the T-block flanges.

As a SAE T-block flanges manufacturer in India we strive to adhere to precision and functionality and ensure that we employ modern technologies and superior materials to ensure reliable flanges. This is made possible by the expertise whereby the flanges acquire the international standard for the intended use.

Table of content

| Type | SAE T-block Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE T-block Flange

SAE T-Block Flange Connectors

3000 PSI SAE T-Block Flange

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Standardized Design

- High Pressure Capability

- Material Variety

- Leakage Prevention

- Versatility

- Agricultural Machinery

- Forestry Machinery

- Lifting and Material Handling Equipment

- Paper Processing

- Mobile Hydraulics

- Building Machinery