Top notch 4 bolt sae threaded flange manufacturer in India

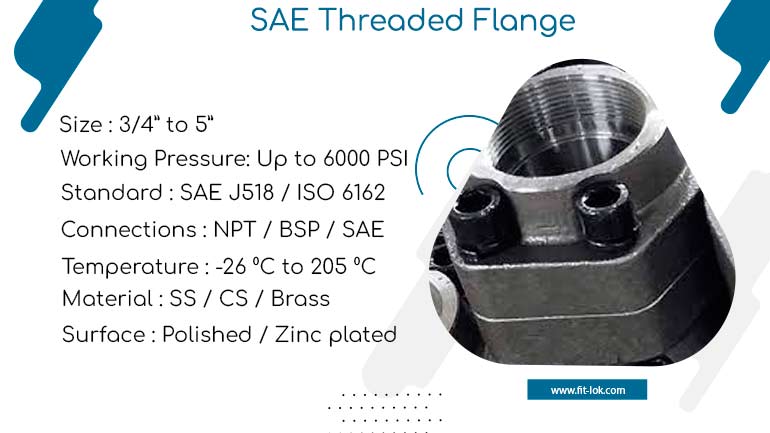

SAE Threaded Flanges exhibit high reliability due to their adherence to the specifications set down by the SAE, They are compatible for use in a wide range of operations. With their threaded design and ability to handle high-pressure conditions. Fit-Lok is SAE Threaded Flange manufacturers in India specialize in producing high-quality, precision-engineered flanges.

4 bolt sae threaded flange are those hydraulic fittings that have internal threaded to enable the direct screwing on the pipe or tube without welding. PerPage connection screwing allows for a tight fitting, whereas an O-ring groove is provided to make it non-leaking. SAE Threaded Flanges are made up of different variety of materials, sizes and pressure ratings and thus it act as a useful component in hydraulic systems. We are one of the leading exporter of SAE Threaded Flanges in countries like UAE, Nigeria and USA.

We keep ready stock of SAE J518 threaded flange in 3/4” to 3”

Internal threading of low voltage elements also saves welding complexities during installation and for maintenance. Mainly used carbon steel, stainless steel and alloy steel make SAE J518 threaded flange highly durable with resistance to corrosion, wearing and mechanical endurances. The threaded design mean that it is very easy to install or swap out, especially in any system where it is likely to be needed as part of an assembly line or as part of a machine where fittings and disconnections are required.

SAE Threaded Flanges serve to be perfect for hydraulic systems where there is a need to join parts with super reinforced threads and no sign of leakage, all without having to weld. They conform to SAE standards to fit present parts; and though specializing in high performance, they are well built to endure heat. These flanges are suitable for use within facilities of the oil & gas industry such as pipelines, industrial machines, and hydraulic systems in marine vessels and equipment.

Table of content

| Type | SAE Threaded Flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE Threaded Flange

4 bolt SAE threaded flange

SAE J518 threaded flange

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 70 |

| 25 | 1″ | M10 | 70 |

| 32 | 1 1/4″ | M10 | 70 |

| 38 | 1 1/2″ | M12 | 130 |

| 51 | 2″ | M12 | 130 |

| 64 | 2 1/2″ | M12 | 130 |

| 76 | 3″ | M16 | 295 |

| 89 | 3 1/2″ | M16 | 295 |

| 102 | 4″ | M16 | 295 |

| 127 | 5″ | M16 | 295 |

- Easy Installation

- Temperature Resistance

- Corrosion Resistance

- Interchangeability

- Sealing Options

- Steel Mills

- Industrial Hydraulics

- Injection Moulding Machinery

- Aluminium Die-Casting Machinery

- Sintering Machinery

- Hydraulic Presses