Top notch Sha blind square flange manufacturer in India

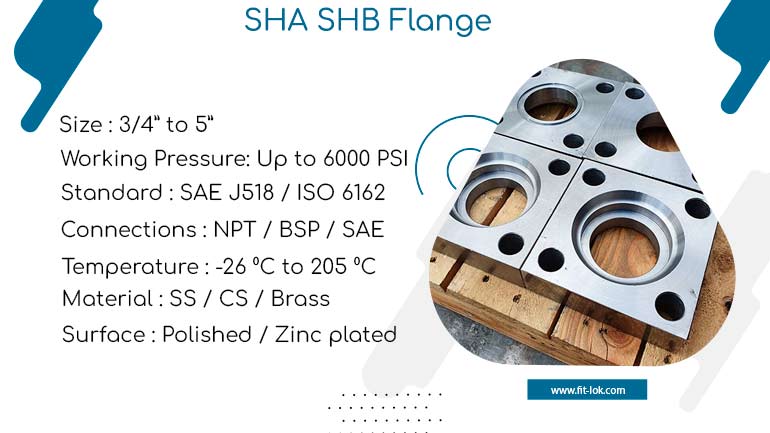

When it comes to the selection of Sha shb flange for their systems, buyers usually look at sizes, pressure ratings and thickness dimensions of the flanges. Meets the international quality standard, Sha blind square flange can be utilized in oil and gas production, construction, automobile manufacturing, and industries dealing with heavy machineries.

We stock and supply Ssa ssb square flange in wide range of sizes

SHA and SHB flanges come in numerous sizes to fit a variety of hydraulic and fluid transferring applications. Special request for non-standard flanges can be made to meet the specific needs of a project as customers are supplied with requested flanges. Different bolt-hole patterns and face diameter are also possible if the designer requires such design. All SHA and SHB flanges are suitable for high pressure hydraulic systems with pressure range normally from 3000 psi (207 bar) up to 6000 psi (414 bar). Although SHA and SHB flanges are designed with rather large safety margins which permit for occasional pressure spikes without jeopardizing overall system safety.

Ssa ssb square flange is designed with a higher thickness to provide greater strength and to accommodate much pressure. Flange face is precision machined to provide a very flat face that able to give adequate sealing with gasket. Designs of bolt-holes are made with precision in order to form a perfect match with the corresponding parts and therefore facilitate installation. Business people should ensure that they get an SHA or SHB flange that fits to the pipe diameter, pressure and system that they intend to serve.

Table of content

| Type | Sha shb flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

Sha shb flange

Sha blind square flange

Ssa ssb square flange

| Working Pressure Kg/cm2 | Size | A | B | C | D | E | F | G | H | L | Screws (Metric) | Screws (UNC) | Or Type | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 414 | 1/2″ | 21,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,24 |

| 414 | 1/2″ (3/8″) | 17,5 | 15.8 | 40,49 | 57 | 18,24 | 46 | 36 | 16 | 9 | M8x30 | 5/16×1″1/4 | 4075 | 0,22 |

| 414 | 3/4″ | 28,0 | 20.9 | 50,80 | 71 | 23,80 | 55 | 35 | 21 | 11 | M10x40 | 3/8×1″1/2 | 4100 | 0,48 |

| 414 | 1″ | 34,0 | 26.6 | 57,15 | 79 | 27,76 | 68 | 41 | 21 | 13 | M12x45 | 7/16×1″3/4 | 4131 | 0,64 |

| 378 | 1″1/4 | 42,8 | 35.1 | 66,68 | 93 | 31,75 | 78 | 44 | 25 | 15 * | M14x45 | 1/2×1″3/4 | 4150 | 1,00 |

| 320 | 1″1/2 | 48,6 | 40.9 | 79,38 | 112 | 36,50 | 94 | 55 | 30 | 17 | M16x50 | 5/8×2″ | 4187 | 1,68 |

| 250 | 2″ | 61,0 | 52.5 | 96,82 | 134 | 44,45 | 114 | 65 | 37 | 21 | M20x70 | 3/4×2″1/2 | 4225 | 2,86 |

| 230 | 2″1/2 | 76,6 | 62 | 123,80 | 180 | 58,70 | 152 | 80 | 45 | 26 | M24x80 | – | 4275 | 6,40 |

| 200 | 3″ | 90,0 | 77.9 | 152,40 | 208 | 71,40 | 178 | 90 | 55 | 33 | M30x100 | – | 4337 | – |

| Metric Size | Flange Size | Screw Thread | Screw Torque (NM) |

| 13 | 1/2″ | M8 | 32 |

| 19 | 3/4″ | M10 | 60 |

| 25 | 1″ | M12 | 60 |

| 32 | 1 1/4″ | M12 | 92 |

| 38 | 1 1/2″ | M16 | 150 |

| 51 | 2″ | M20 | 150 |

| 64 | 2 1/2″ | M24 | 150 |

| 75 | 3″ | M30 | 295 |

- Standardized Design

- High Pressure Capability

- Leakage Prevention

- Versatility

- Material Variety

- Agricultural Machinery

- Forestry Machinery

- Lifting and Material Handling Equipment

- Paper Processing

- Mobile Hydraulics

- Building Machinery