Rely on us as a top-notch UNS S31254 Compression Union manufacturer in India

Fit-lok is a reliable manufacturer and provider of a wide range of goods required for industrial applications. To fulfil the unique needs of their clients, they manufacture a variety of components and products in a variety of alloys and specifications. SMO 254 stands out as a good material for manufacturing Compression Tube Fittings among the materials they work with.

SMO 254 is an Austenitic Stainless-Steel material that is very beneficial in the fabrication of SMO 254 Compression Tube Fittings. These fittings are of high quality and meet the needs of a variety of industries.

Obtain 254 SMO ferrule fittings at affordable prices from the stockist.

Fit-lok uses premium materials in their manufacturing procedures to assure the excellent quality of their goods. During the production of SMO 254 Compression Tube Fittings, they rigorously adhere to precise standard methods and rules. To maintain the quality of their products, they examine the quality of the raw materials before beginning the manufacturing process.

Quality testing is an important part in their manufacturing process that ensures the finished SMO 254 Compression Tube Fittings fulfil industry standards and client requirements. These fittings have outstanding mechanical features like strength, flexibility, and hardness, making them dependable and long-lasting for a variety of industrial applications. With a focus on quality, adherence to standards, and commitment to customer satisfaction, Fit-lok continues to deliver high-grade SMO 254 Compression Tube Fittings that meet the needs of their clients and various industries.

Table of content

- 254 SMO tube fittings Specification

- Types of SMO 254 compression fittings

- EN 1.4547 male connector chemical composition

- 254 SMO Super Duplex instrumentation fittings mechanical composition

- 254 SMO ferrule fittings equivalent grade

- Size chart of 1.4547 SMO hydraulic fittings

- SMO 254 flare fittings Pressure rating

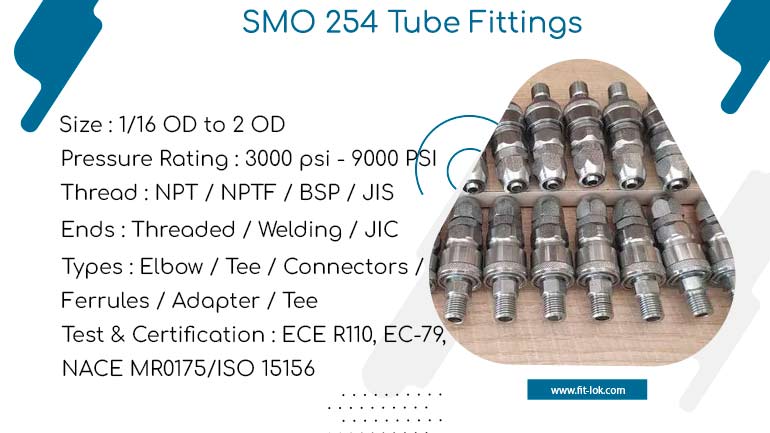

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

|---|---|

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

254 SMO ferrule fittings

1.4547 SMO hydraulic fittings

SMO 254 flare fittings

SMO 254 bulkhead union

Alloy 254 SMO compression tube fittings

UNS S31254 instrumentation tube fittings

| SMO 254 | C | Ni | Cr | Mn | Mo | Fe | Si | S | Cu | P |

| 0.002 maximum | 17.05 to 18.05 | 19.05 to 20.05 | 1 maximum | 6 to 6.05 | to | 0.08 maximum | 0.001 maximum | 0.05 to 1 | 0.003 maximum |

Our comprehensive range of 1.4547 SMO hydraulic fittings dimensions and sizes allows you to find the perfect fit for your specific application

| Melting Point | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 1320 to 1390 ℃ | 8.0 g/cm3 | 650 | 300 | 35 % |

| STANDARD | GOST | WERKSTOFF NR. | UNS | JIS | EN | AFNOR | SIS |

| SMO 254 | – | 1.4547 | S31254 | – | X1CrNiMoCuN20-18-7 | Z1 CNDU 20.18.06Az | 2378 |

Trust our expertise in SMO 254 flare fittings to fulfill the requirements of both instrumentation and industrial applications with precision.

| Tube OD (in) | Thread Size (in) | Hex Flat (in) |

|---|---|---|

| 1/16 | 1/16 | 0.31 |

| 1/8 | 1/8 | 0.38 |

| 3/16 | 1/8 | 0.38 |

| 1/4 | 1/4 | 0.46 |

| 5/16 | 1/4 | 0.46 |

| 3/8 | 3/8 | 0.54 |

| 1/2 | 1/2 | 0.71 |

| 5/8 | 1/2 | 0.71 |

| 3/4 | 3/4 | 0.83 |

| 7/8 | 3/4 | 0.83 |

| 1 | 1 | 1.02 |

| Dash Size | Nominal Tube/Pipe Size | SAE100R2 | National Pipe Tapered Fuel (NPTF) | National Pipe Straight Mechanical (NPSM) | JIC 37° Flare Hydraulic SAE J514 | Flareless Compression SAE J514 | ||

| Male | Female | Female Swivel | Male | Female Swivel | ||||

| -02 | 1/8″ | 10000 | 5000 | 6000 | ||||

| -04 | 1/4″ | 5000 | 9500 | 4500 | 5000 | 8500 | 5500 | 6000 |

| -05 | 5/16″ | 4250 | 8500 | 5000 | ||||

| -06 | 3/8″ | 4000 | 8000 | 3500 | 4000 | 7000 | 4000 | 6000 |

| -08 | 1/2″ | 3500 | 6000 | 3500 | 3500 | 6000 | 4000 | 6000 |

| -10 | 5/8″ | 2750 | 5500 | 3000 | 5000 | |||

| -12 | 3/4″ | 2250 | 5000 | 3000 | 3500 | 4000 | 3000 | 4500 |

| -14 | 7/8″ | 2000 | 4000 | 3000 | ||||

| -16 | 1″ | 2000 | 4000 | 2500 | 3000 | 3500 | 2500 | 4000 |

| -20 | 1-1/4″ | 1625 | 3000 | 2000 | 2000 | 3500 | 2000 | |

| -24 | 1-1/2″ | 1250 | 2000 | 1500 | 1500 | 2000 | 1500 | |

| -32 | 2″ | 1125 | 2000 | 1400 | 1500 | 1250 | 1250 | |

We take pride in being a trusted En 1.4547 single ferrule fittings supplier in India

Application of 254 SMO ferrule fittings

- Construction and architecture

- Industrial machinery

- Power generation

- Textile industry

- Brewing equipment

Packaging of 254 SMO Super Duplex instrumentation fittings

- Plastic or Paper Sleeves

- Wooden Crates

- Cardboard Boxes

- Palletizing

- Strapping

Frequently asked questions

What are the key features of EN 1.4547 male connector?

EN 1.4547 male connector are known for their exceptional corrosion resistance, high strength, and excellent resistance to chloride-induced stress corrosion cracking.

What is the temperature range in which 254 SMO Super Duplex instrumentation fittings can operate?

254 SMO Super Duplex instrumentation fittings can operate in a wide temperature range from cryogenic temperatures up to approximately 300°C (572°F).

How are 254 SMO ferrule fittings commonly manufactured?

254 SMO ferrule fittings are typically manufactured using processes such as seamless or welded tube production, followed by precision machining or forming to achieve the desired fitting shape.

What are the typical applications of 1.4547 SMO hydraulic fittings?

1.4547 SMO hydraulic fittings find applications in industries such as chemical processing, desalination plants, marine environments, and offshore oil and gas platforms, where corrosion resistance is critical.

Are SMO 254 flare fittings compatible with other materials?

SMO 254 flare fittings are compatible with a wide range of materials, including stainless steel, carbon steel, and various alloys, making them versatile for different piping systems.