Top notch ASME SA213 TP304 Tube supplier in India

Fit-lok manufactures and supplies high-quality ASME SA 213 TP 304 Tube in a variety of types, wall thicknesses, dimensions, and specifications. Using high-quality raw materials supplied by our most trusted market vendors, as well as cutting-edge machinery. Our customers all over the world appreciate our high-quality Stainless Steel 304 Seamless Tubing. If you are interested in purchasing these UNS S30400 round tube, please contact us and request a free quotation.

304 SS ERW Tubing can withstand extreme thermal cycling

Because we are one of the largest suppliers of Seamless 304 SS Tubing, our 304 Stainless Steel Tube Price is very competitive in the market. The most common shape is round. And, while the Stainless Steel 304 Seamless Round Tube is designed for use in high-temperature applications, it can also be used in room temperatures and under normal atmospheric conditions. Under normal conditions, the 304 ss tubes are also resistant to natural acids. Our Stainless Steel 304 Seamless Tube is suitable for use in boilers, heat exchangers, condensers, and super heaters.

We adhere to a strict quality control system for 304 Stainless Steel Tube and provide test certificates in accordance with EN 10204 3.1. Our top priority is to maintain a strict quality control system and an excellent after-sales service system that can guarantee and track the quality of our products from raw material procurement to manufacturing processes, finished products, and after-sales service.

Table of content

- Stainless Steel 304 Tube Specification

- ASME SA 213 TP304 Tubing Size chart

- 304 Stainless Steel Welded Tube chemical composition

- SS 304 Seamless Tubes mechanical properties

- SS 304 Boiler Tube Equivalent grade

- UNS S30400 Tube Surface Finish

- DIn 1.4301 Tube Tolerance

- Various types of Stainless Steel 304 Tube

- Stock list of 304 SS Tube

- Packging and Marking of ASTM A213 TP304 Tube

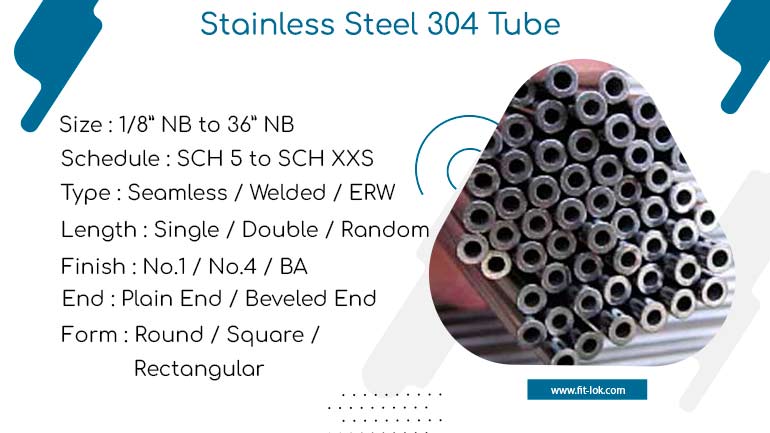

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 304 | min. | – | – | – | – | – | 18.0 | – | 8.0 | – |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||

UNS S30400 Round Tube and Stainless Steel 304 Welded Tube can have a thickness ranging from Schedule 5 to Schedule XXS.

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304 | 515 | 205 | 40 | 92 | 201 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

Stockist of SS 304 Seamless Tubes and DIN 1.4301 Welded Tube in sizes range from 1/2″ to 6″

| Surface Finish | Internal Surface(ID) | Exterbal Surface(OD) | |||

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μ inch | μm | μ inch | μm | ||

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

| Specification | Size OD Range Inches | Tolerances | |||

|---|---|---|---|---|---|

| O.D. | Wall | ||||

| Plus | Minus | Plus | Minus | ||

| ASTM-A-632 | Under 0.094 | .002″ | .000″ | 10% | 10% |

| Welded & Seamless | .094 to 0.187 | .003″ | .000″ | 10% | 10% |

| Cold Finished | .188 to 0.500 | .004″ | .000″ | 10% | 10% |

| ASTM-A-269 | Under 0.500 | .005″ | .005″ | 15% | 15% |

| Welded & Seamless | 0.500 to 1.499 | .005″(1) | 005″ | 10% | 10% |

| General Service | 1.500 to 3.499 | .010″(2) | .010″ | 10% | 10% |

| Cold Finished | 3.500 to 5.499 | .015″(3) | .015″ | 10% | 10% |

| Hot Finished | 5.500 to 8.000 | .030″ | .030″ | 10% | 10% |

304 Stainless Steel Tube

ASTM A213 Grade 304 tube

SA213 TP304 ERW Tube

SS 304 Seamless Tubes

UNS S30400 Round Tube

ASTM A213 TP304 Hydraulic Tubing

We sale ASTM A213 TP304 Hydraulic Tubing at most reasonable price in Mumbai

| Stainless Steel 304 Tube | 304 Stainless steel coil Tube |

| 304 Stainless Steel Oval Tube | Stainless Steel 304 Instrumentation Tube |

| SS 304 Tube | 304 Stainless Steel Round Tube |

| Tube Inox 304 | Mirror Welded 304 Stainless Steel Tube |

| 304 Stainless Steel Perforated Tube | hot dip galvanized stainless steel 304 Tube |

| 304 Ornamental Round Tube | 304 Stainless Rectangular Tube |

| 304 Stainless Steel Tube | 304 round square rectangular stainless steel Tube |

| Stainless Steel 304 Round Tube | 304 Stainless Steel Welded Tube |

| Alloy 304 Exhaust Tube | SS 304 Seamless Tube |

| ASTM A213 304 SS Tube | 304 stainless steel capillary Tube |

- Wooden Boxes

- Plastic Bags

- Steel Strips Bundled

Application of stainless steel 304 tubes

- Aerospace

- Food & Dairy Plants

- Paper Industries

- Chemical Industries

- Desalination Plant

- Thermal & Nuclear Power Plants

- Fertilizer Plant

- Oil & Gas Exploration

- Pharmaceutical Plant

Frequently asked questions

What are the common applications of stainless steel 304 tubes?

Stainless steel 304 tubes are commonly used in industries such as construction, automotive, and food processing.

How does the mechanical strength of SS 304 tubes compare to other grades?

SS 304 tubes exhibit good mechanical strength, making them suitable for various structural applications.

What is the average wall thickness available for AISI 304 welded tubes?

The wall thickness of AISI 304 welded tubes can vary, but it typically ranges from 0.5mm to 3mm.

Can 304 SS ERW Tubing be welded easily?

Yes, 304 SS ERW Tubing can be easily welded using conventional welding techniques.

What is the typical length range of ASME SA213 TP304 Tube?

ASME SA213 TP304 Tube are available in various lengths, typically ranging from a few feet to several meters.