One of the biggest ASTM A213 TP304l Tube supplier in India

The letter L in 304L Stainless Steel Tube denotes extremely low carbon. Because of the reduced carbon content, 304L tubing solutions have greater corrosion resistance than SS 304 tube. SA 213 TP304L superheater and reheater tubes can withstand high temperatures and pressures. The primary distinction between reheater and superheater ASTM A213 TP304L tubes is their steam pressure.

The SS 304L Seamless Tube has a higher pressure capacity and strength than the SS 304L welded tubes. As a result, seamless 304L Tubing solutions are widely utilised in high-pressure equipment, as well as in the thermal and boiler industries. The welded seam of the SS 304L Welded Tube is often a weak place that may have an impact on its overall performance quality.

The dimensional accuracy and surface finish of UNS S30400 Welded Tubes and Cold redrawn SS 304l Tubes are important factors to consider when evaluating their price and quality.

The 304L SS ERW Tubing solutions are created by rolling the metal first and then welding it across the length (longitudinally). Extruding the material to the necessary length produces the seamless 304L Stainless Steel Square Tubing options. Thus, ERW pipes have seams or joints that run parallel to their length, whereas seamless pipes do not.

They are stronger since there are no weak seams in the seamless Inox 1.4306 Tube. As a result, seamless tubes are chosen in a variety of high-pressure applications. It covers services in hydrocarbon refineries and industries, among other things. ASTM A554 TP 304L ERW tubes are intended for use in low to medium pressure applications. They are mostly used for the transfer of water, oil, and other liquids.

Table of content

- Specification of Stainless Steel 304L Tube

- ASTM A213 Grade 304L Round Tube chemical composition

- SS 304L Welded Tube Mechanical properties

- SA213 TP304L tubing Physical properties

- AISI 304L Tube Equivalent grade

- Different types of ASME SA 213 TP 304L Tube

- Size chart of 304L SS Erw tubing

- Stock list of SS 304l tube

- SS 304L Cold Drawn Tube dimensions

- Testing of ASTM A213 TP 304L Polished Tube

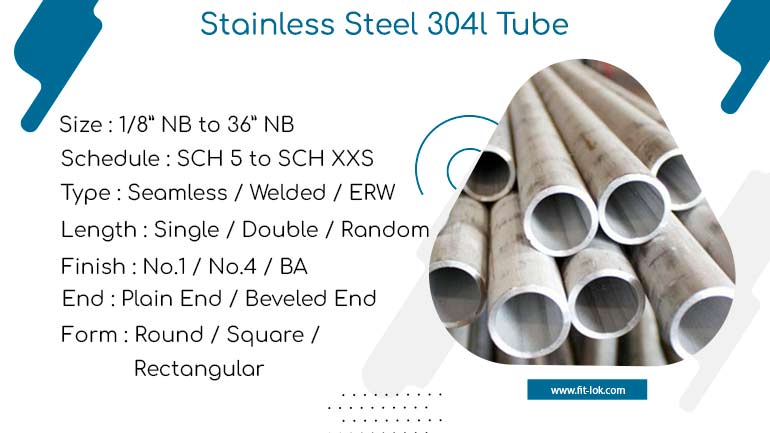

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304l | min. | – | – | – | – | – | 18.0 | – | 8.00 | – |

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.00 | 0.10 | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304l | 485 | 170 | 40 | 92 | 201 |

Buy ASME SA 213 TP 304L tubing and 304l Stainless Steel Tubing in a variety of sizes ranging from 12mm to 260mm

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 304L | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | GOST | ||

|---|---|---|---|---|---|---|---|---|

| BS | En | No | Name | |||||

| 304l | S30403 | 304S31 | 58E | 1.4306 / 1.4307 | X5CrNi18-10 | 2332 | SUS 304L | 03Х18Н11 |

The thickness of WNR 1.4306 ERW Tube can fall anywhere between Schedule 5 and Schedule XXS.

304l Stainless Steel Tubing

WNR 1.4306 ERW Tube

UNS S30400 Welded Tubes

Cold redrawn SS 304l Tubes

SA213 304L SS Thin Wall Tubing

ASTM A213 Grade 304L Seamless Tube

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

| ASTM A249 TP 304L Electropolished Tubing | 304L Stainless Steel Rectangular Tube |

| UNS S30403 Square Tubing | Stainless Steel 1.4306 Polished Tube |

| ASME SA249 TP 304L Tubing | Stainless Steel 304L Fabricated Tube |

| 304L Stainless Steel 12mm Tube | ASME SA249 TP 304L Seamless Tubing |

| SS A249 TP304L High Pressure Tube | 304L SS Thin Wall Tubing |

| Stainless Steel 1.4306 Electropolished Tubes | ASME SA249 TP 304L Cold Drawn Seamless Tube |

| Stainless Steel 304L Hydraulic Tubing | 304L SS Coiled Tube |

| ASTM A249 TP 304L ERW Tube | SS A249 TP304L Electropolished Tube |

| 304L Stainless Steel Rectangular Tubing | Stainless Steel 1.4306 CDW Tube |

| ASME SA249 TP 304L Electropolish Tube | UNS S30403 Capillary Tubing |

Do you have trouble locating the best SA213 304L SS Thin Wall Tubing distributors with prompt delivery

| OD MM | ID MM | WALL MM | OD INCHES | ID INCHES | WALL INCHES |

|---|---|---|---|---|---|

| 2.00 | 1.00 | 0.50 | 0.079 | 0.039 | 0.020 |

| 2.00 | 1.50 | 0.25 | 0.079 | 0.059 | 0.010 |

| 2.50 | 1.50 | 0.50 | 0.099 | 0.059 | 0.020 |

| 3.00 | 2.40 | 0.30 | 0.118 | 0.095 | 0.012 |

| 4.00 | 2.00 | 1.00 | 0.157 | 0.079 | 0.039 |

| 4.50 | 3.50 | 0.50 | 0.177 | 0.137 | 0.020 |

| 5.00 | 2.00 | 1.50 | 0.197 | 0.079 | 0.059 |

| 5.00 | 3.00 | 1.00 | 0.197 | 0.118 | 0.040 |

| 5.00 | 3.50 | 0.75 | 0.197 | 0.137 | 0.030 |

| 5.00 | 4.00 | 0.50 | 0.197 | 0.157 | 0.020 |

| 5.00 | 4.50 | 0.25 | 0.197 | 0.177 | 0.010 |

| 6.00 | 2.00 | 2.00 | 0.236 | 0.079 | 0.080 |

| 6.00 | 3.00 | 1.50 | 0.236 | 0.118 | 0.059 |

| 6.00 | 4.00 | 1.00 | 0.236 | 0.157 | 0.040 |

| 6.00 | 4.50 | 0.75 | 0.236 | 0.177 | 0.030 |

| 6.00 | 5.00 | 0.50 | 0.236 | 0.197 | 0.020 |

| 7.00 | 5.00 | 1.00 | 0.276 | 0.197 | 0.040 |

| 8.00 | 4.00 | 2.00 | 0.315 | 0.157 | 0.079 |

| 8.00 | 5.00 | 1.50 | 0.315 | 0.197 | 0.059 |

| 8.00 | 6.00 | 1.00 | 0.315 | 0.236 | 0.040 |

| 8.00 | 7.00 | 0.50 | 0.315 | 0.276 | 0.020 |

| 9.00 | 6.00 | 1.50 | 0.354 | 0.236 | 0.059 |

| 10.00 | 6.00 | 2.00 | 0.394 | 0.236 | 0.079 |

| 10.00 | 7.00 | 1.50 | 0.394 | 0.276 | 0.059 |

| 10.00 | 8.00 | 1.00 | 0.394 | 0.315 | 0.040 |

| 10.00 | 9.00 | 0.50 | 0.394 | 0.354 | 0.020 |

| 12.00 | 10.00 | 1.00 | 0.472 | 0.394 | 0.039 |

| 14.00 | 11.00 | 1.50 | 0.551 | 0.433 | 0.059 |

| 14.00 | 12.00 | 1.00 | 0.551 | 0.472 | 0.040 |

| 15.00 | 12.00 | 1.50 | 0.591 | 0.472 | 0.060 |

| 15.00 | 13.00 | 1.00 | 0.591 | 0.512 | 0.040 |

| 16.00 | 13.00 | 1.50 | 0.630 | 0.512 | 0.059 |

| 18.00 | 14.00 | 2.00 | 0.709 | 0.551 | 0.079 |

| 20.00 | 17.00 | 1.50 | 0.787 | 0.669 | 0.060 |

| 20.00 | 18.00 | 1.00 | 0.787 | 0.709 | 0.039 |

- Dimension size inspect

- Visual Test

- Nondestructive Test

Application of 304L SS tubes

- Oil mills

- Compressed air distribution

- Dairies

- Radiator heating

- Metal and chemical industries

- Paper industries

Packaging of Alloy 304L Tubing

- Protective Wrapping

- Bundle Formation

- End Caps or Plugs

- Padding and Cushioning

- Outer Packaging

- Labelling and Identification

- Moisture Protection

Frequently asked questions

What is the composition of ASME SA 213 TP 304L tubing?

The composition of ASME SA 213 TP 304L tubing typically includes 18% chromium and 8% nickel.

What is the melting point of ASTM A213 Grade 304L Seamless Tube?

The melting point of ASTM A213 Grade 304L Seamless Tube is approximately 1400-1450°C (2552-2642°F).

Are 304l Stainless Steel Tubing magnetic?

Yes, 304l Stainless Steel Tubing are generally magnetic due to the presence of iron in their composition.

Can WNR 1.4306 ERW Tube be used for structural applications?

Yes, WNR 1.4306 ERW Tube are commonly used for structural applications due to their strength and durability.

What is the weight of UNS S30403 Welded Tubes?

The weight of UNS S30403 Welded Tubes depends on their dimensions. The weight per unit length can be calculated using the specific density of stainless steel.