ASTM A213 TP310 Tube supplier in India

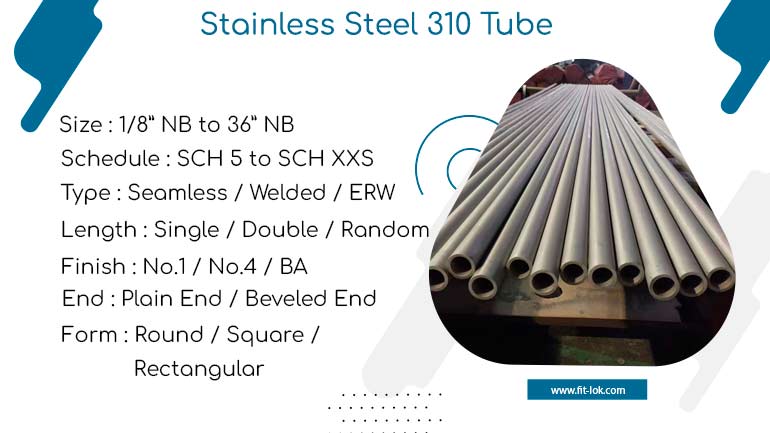

The Stainless Steel 310 Tube is comprised of austenitic stainless steel, which contains nickel and chromium. The Tubes are well-known for their durability. The ASTM A213 TP310 Tube has improved weldability and ductility, making it suitable for a wide range of applications. They operate well at high temperatures but have worse corrosion resistance qualities than other material classes. 310 Stainless Steel Tube is available in a variety of shapes and sizes from reputable manufacturers in India. Dimensions and surface treatments can also be changed. These tubes come in a variety of styles, including seamless, electric fusion welded, and electric resistance welded.

Hot rolled 310 Stainless Steel Square Tubing and SA 213 Tp 310 welded Tube exhibits excellent mechanical strength and durability.

SA 213 Tp 310 welded Tube is generally utilised in situations requiring less absolute toughness. They must also have excellent dimensional precision in order to do their job appropriately. The SA 213 Tp 310 welded Tube are capable of performing services in high temperature and low sulphur (mainly gas) conditions. In high temperature settings, the low carbon variant of the Aisi 310 Square Tubing does not give much resistance or strength.

Alloy 310 ERW Tube offer exceptional mechanical qualities, such as a minimum tensile strength of 520 MPa and a minimum high yield strength of 205 MPa. It also has a high hardness and a high elongation percentage. The DIN 1.4841 Cold Drawn Tube has a strong conductivity to electricity and is also heat resistant. Depending on the temperature at which it is used, the SS 310 Seamless Tubing is wear and tear resistant as well as corrosion resistant. The SS 310 tube material is machinable, but it must be done slowly and heavily since the oxide layer generated outside the material can become extremely hard. This work hardening issue must be treated with extreme caution.

Table of content

- 310 Stainless Steel Tubing Specification

- UNS S31000 seamless Tube Sizes

- ASME SA 213 TP 310 Tube Chemical Composition

- AISI 310 Welded Tubes Physical Properties

- DIN 1.4845 Round Tubes Mechanical Properties

- SS 310 boiler tubes Equivalent

- 310 SS tube stock list

- ASTM A213 310 Tube Dimensions

- SS 310 seamless tubes Tolerances

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

| Wall Thickness | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

We offer Aisi 310 Square Tubing and Alloy 310 ERW Tube that is cut to length in any size

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.0 | 1.00 | 0.045 | 0.03 | 26.0 | 21.0 | – | ||

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 310H | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Stainless Steel Type 310 Round Tube and DIN 1.4841 Cold Drawn Tube are often used in heat exchangers, condensers, furnace components

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310H | S31009 | – | – | – | – | – | – |

| Stainless Steel 310S Pipe | 4 inch 310H Stainless Steel Seamless Pipe |

| 310H Stainless Steel Pipes | ASME SA312 TP 310S Welded Pipes |

| SS A312 TP310H Seamless Steel Pipe | ASTM A312 TP 310H Cold Drawn Welded Pipes |

| 310H Stainless Steel Welded Pipe | UNS S31000 Cold Drawn Pipes |

| ASME SA312 TP 310S ERW Pipe | Schedule 5S Stainless Steel 1.4841 Seamless Pipes |

| UNS S31000 EFW Pipe | Schedule 40 310S SS Pipe |

| Stainless Steel 1.4841 Cold Drawn Seamless Pipes | ASME SA312 TP 310S Precision Pipe |

| Stainless Steel 310S Seamless Steel Precision Pipe | High pressure SS A312 TP310H Pipe |

| 310S SS Cold Drawn Seamless Pipes | Stainless Steel 1.4841 Electropolished Pipe |

| ASME SA312 TP 310S Custom Pipe | Stainless Steel 310S Cold Drawn Pipes |

Choose the perfect UNS S31000 Annealed Tube and 310 Stainless Steel Exhaust Tubing dimensions and sizes for your project requirements

| OD MM | ID MM | WALL MM | OD INCHES | ID INCHES | WALL INCHES |

|---|---|---|---|---|---|

| 2.00 | 1.00 | 0.50 | 0.079 | 0.039 | 0.020 |

| 2.00 | 1.50 | 0.25 | 0.079 | 0.059 | 0.010 |

| 2.50 | 1.50 | 0.50 | 0.099 | 0.059 | 0.020 |

| 3.00 | 2.40 | 0.30 | 0.118 | 0.095 | 0.012 |

| 4.00 | 2.00 | 1.00 | 0.157 | 0.079 | 0.039 |

| 4.50 | 3.50 | 0.50 | 0.177 | 0.137 | 0.020 |

| 5.00 | 2.00 | 1.50 | 0.197 | 0.079 | 0.059 |

| 5.00 | 3.00 | 1.00 | 0.197 | 0.118 | 0.040 |

| 5.00 | 3.50 | 0.75 | 0.197 | 0.137 | 0.030 |

| 5.00 | 4.00 | 0.50 | 0.197 | 0.157 | 0.020 |

| 5.00 | 4.50 | 0.25 | 0.197 | 0.177 | 0.010 |

| 6.00 | 2.00 | 2.00 | 0.236 | 0.079 | 0.080 |

| 6.00 | 3.00 | 1.50 | 0.236 | 0.118 | 0.059 |

| 6.00 | 4.00 | 1.00 | 0.236 | 0.157 | 0.040 |

| 6.00 | 4.50 | 0.75 | 0.236 | 0.177 | 0.030 |

| 6.00 | 5.00 | 0.50 | 0.236 | 0.197 | 0.020 |

| 7.00 | 5.00 | 1.00 | 0.276 | 0.197 | 0.040 |

| 8.00 | 4.00 | 2.00 | 0.315 | 0.157 | 0.079 |

| 8.00 | 5.00 | 1.50 | 0.315 | 0.197 | 0.059 |

| 8.00 | 6.00 | 1.00 | 0.315 | 0.236 | 0.040 |

| 8.00 | 7.00 | 0.50 | 0.315 | 0.276 | 0.020 |

| 9.00 | 6.00 | 1.50 | 0.354 | 0.236 | 0.059 |

| 10.00 | 6.00 | 2.00 | 0.394 | 0.236 | 0.079 |

| 10.00 | 7.00 | 1.50 | 0.394 | 0.276 | 0.059 |

| 10.00 | 8.00 | 1.00 | 0.394 | 0.315 | 0.040 |

| 10.00 | 9.00 | 0.50 | 0.394 | 0.354 | 0.020 |

| 12.00 | 10.00 | 1.00 | 0.472 | 0.394 | 0.039 |

| 14.00 | 11.00 | 1.50 | 0.551 | 0.433 | 0.059 |

| 14.00 | 12.00 | 1.00 | 0.551 | 0.472 | 0.040 |

| 15.00 | 12.00 | 1.50 | 0.591 | 0.472 | 0.060 |

| 15.00 | 13.00 | 1.00 | 0.591 | 0.512 | 0.040 |

| 16.00 | 13.00 | 1.50 | 0.630 | 0.512 | 0.059 |

| 18.00 | 14.00 | 2.00 | 0.709 | 0.551 | 0.079 |

| 20.00 | 17.00 | 1.50 | 0.787 | 0.669 | 0.060 |

| 20.00 | 18.00 | 1.00 | 0.787 | 0.709 | 0.039 |

| ASTM-A-632 | Under 0.094 | .002″ | .000″ | 10% | 10% |

| Welded & Seamless | .094 to 0.187 | .003″ | .000″ | 10% | 10% |

| Cold Finished | .188 to 0.500 | .004″ | .000″ | 10% | 10% |

Application of ASTM A213 TP310 Tube

- Dairy equipment

- Automotive manufacturing

- Aerospace industry

- Marine applications

- Brewing equipment

Packaging of SA 213 Tp 310 welded Tube

The packaging approach for steel tubes is tailored to each pipe’s type and dimensions. Our packaging methods cater to the standard pipe types, but added precautions are advised during sealift handling and transportation to prevent damages related to movement and bending.

Frequently asked questions

What are the key characteristics of SA 213 TP310 Seamless Tube?

SA 213 TP310 Seamless Tube exhibit excellent high-temperature strength, oxidation resistance, and corrosion resistance.

What is the chemical composition of 310 Stainless Steel Square Tubing?

The chemical composition of 310 Stainless Steel Square Tubing typically includes around 25% chromium and 20% nickel, with small amounts of other elements like iron, manganese, and silicon.

Are SA 213 Tp 310 welded Tube suitable for high-temperature applications?

Yes, SA 213 Tp 310 welded Tube are specifically designed for high-temperature applications, with a maximum operating temperature of approximately 1150°C (2100°F).

What is the maximum operating temperature for Aisi 310 Square Tubing?

The maximum operating temperature for Aisi 310 Square Tubing is around 1150°C (2100°F), making them suitable for high-temperature environments.

How does the corrosion resistance of Alloy 310 ERW Tube compare to SS 304 tubes?

Alloy 310 ERW Tube offer superior corrosion resistance compared to SS 304 tubes, particularly in high-temperature and oxidizing environments.